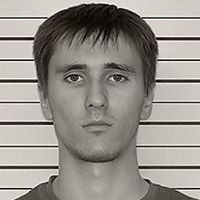

Andrew B Witkowski

age ~76

from Oakbrook Terrace, IL

- Also known as:

-

- Andrew D Witkowski

- Andrew B Witowski

- Adrew Witkowski

- Barbara Witkowski

- Julie Witkowski

Andrew Witkowski Phones & Addresses

- Oakbrook Terrace, IL

- Apollo Beach, FL

- Los Angeles, CA

- 1S616 Macarthur Dr #S, Oakbrook Terrace, IL 60181

Resumes

Andrew Witkowski

view sourceUs Patents

-

Energy Absorbing Lift Bracket

view source -

US Patent:20090095860, Apr 16, 2009

-

Filed:Oct 16, 2007

-

Appl. No.:11/872976

-

Inventors:Timothy Yoon - Des Plaines IL, US

Andrew B. Witkowski - Oakbrook Terrace IL, US

Martin R. Zielke - Homer Glen IL, US

Steven C. Bielaga - Naperville IL, US

Tyler R. Vincer - Elmhurst IL, US

Thomas G. Grotto - Winfield IL, US -

Assignee:International Engine Intellectual Property Company , LLC - Warrenville IL

-

International Classification:E02D 27/44

-

US Classification:24822511

-

Abstract:A lift bracket () includes a topmost portion () having an opening () arranged for engagement with an engagement portion of a lifting apparatus. The topmost portion () is substantially flat and defines a first plane (A-A). A base portion () of the lift bracket () has at least one fastener opening () for fastening the base portion to the engine. The base portion () also lies in the first plane (A-A). A yield structure () is disposed between the topmost portion () and the base portion (), and includes a mid-portion () that defines at least one second plane (B-B) that is spaced and parallel to the first plane (A-A). When a tensile force is applied to the topmost portion (), the yielding structure () yields, the topmost portion displaces away from the base portion (), and the second plane (B-B) displaces towards the first plane (A-A).

-

Crankcase And Main Bearing Cap Construction

view source -

US Patent:20110048367, Mar 3, 2011

-

Filed:Sep 2, 2009

-

Appl. No.:12/552555

-

Inventors:Martin R. Zielke - Lockport IL, US

Andrew B. Witkowski - Oakbrook Terrace IL, US

Roger C. Kenitz - Chicago IL, US -

Assignee:International Engine Intellectual Property Company LLC - Warrenville IL

-

International Classification:F02F 7/00

F16C 35/00

B23P 15/00 -

US Classification:123195 R, 384433, 2988801

-

Abstract:A method for manufacturing an engine includes the steps of: casting a side skirt having first and second opposing sidewalls and casting a transverse wall of the cast material connecting the sidewalls. The transverse wall will form a bulkhead and a main bearing cap. A first void and a second void are cast into the transverse wall on opposite lateral sides of a main bearing journal location, each void adjacent to one of the sidewalls. A main bearing journal hole is then machined into the transverse wall. Cast material is removed along a first removal path from the edge of the transverse wall and ending into the first void, and along a second removal path from the edge of the transverse wall and ending into the second void. A tool exerts an opening force within the circular bore to fracture the cast material along the first and second fracture planes to separate the main bearing cap from the bulkhead. Before fracturing the cast material along the first and second fracture planes, main bearing bolt holes and cross bolt holes can be machined into the bulkhead and the bearing cap. A spacer piece can be fit into the removal paths when reassembling the bearing cap to the bulkhead.

-

Automotive Engine With Improved Multifilter Lubrication System

view source -

US Patent:45122997, Apr 23, 1985

-

Filed:Dec 12, 1983

-

Appl. No.:6/560762

-

Inventors:John J. Egan - Wheaton IL

Andrew B. Witkowski - Oakbrook Terrace IL -

Assignee:International Harvester Company - Chicago IL

-

International Classification:F01M 100

-

US Classification:123196A

-

Abstract:An automotive engine is provided with an improved multifilter oil lubrication system. At least two filters are provided wherein the majority of the oil flow is through a primary coarse filter. At least one fine secondary filter is provided to filter the oil not going to the coarse filter. The oil from the fine filter is delivered directly to the engine. The improved system may be used with a smaller pump using less horsepower than previously possible by multifilter bypass systems. The addition of the fine filtration increases engine life.

Classmates

Andrew Witkowski

view sourceSchools:

St. Boniface School Peoria IL 1993-1997

Community:

John Stromberger, Tony Maggio, Christina Jordan, Dana Gulley, Christina Simpson, Cari Coons, Loren Farris, Frank Hubble, John Dempsey, Paul Moreno

St. Boniface School, Peor...

view sourceGraduates:

Christina Simpson (1989-1993),

Andrew Witkowski (1993-1997),

David Matranga (1948-1952),

Larry Rutherford (1971-1975),

Robert Terlep (1952-1956)

Andrew Witkowski (1993-1997),

David Matranga (1948-1952),

Larry Rutherford (1971-1975),

Robert Terlep (1952-1956)

Andrew Witkowski

view source

Andrew Witkowski

view source

Andrew Witkowski

view source

Andrew Witkowski

view source

Andrew Witkowski

view source

Andrew Witkowski

view source

Andrew Witkowski

view source

Andrew Witkowski

view sourceMyspace

Youtube

Googleplus

Andrew Witkowski

Work:

Parks and Recreation - Maintenance (2010)

DeFazios Pizzeria - Dishwasher (2009)

DeFazios Pizzeria - Dishwasher (2009)

Education:

LaSalle Institute - High School

Tagline:

My names Andrew, I go to LaSalle Institute and am on the drill team.

Andrew Witkowski

Flickr

Get Report for Andrew B Witkowski from Oakbrook Terrace, IL, age ~76