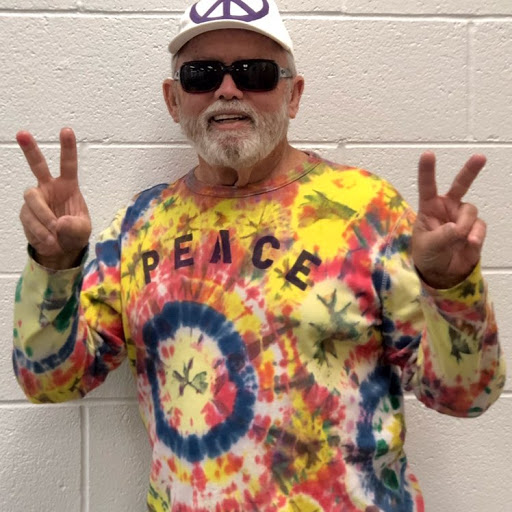

Bobby Don Morris

age ~87

from Greer, SC

- Also known as:

-

- Bobby D Morris

- Robert W Morris

Bobby Morris Phones & Addresses

- Greer, SC

- West Columbia, SC

- Columbia, SC

Work

-

Company:Person 2 person

-

Address:651 Turner Rd, Glympville, SC 29126

-

Phones:(803)4613339

-

Position:Ceo

-

Industries:Testing Laboratories

License Records

Bobby Joe Morris Jr.

License #:

MA.001522 - Active

Issued Date:

Aug 18, 2011

Expiration Date:

Sep 14, 2017

Type:

Medication Administration (V)

Bobby Joe Morris Jr.

License #:

PIC.018512 - Active

Issued Date:

Aug 6, 2008

Expiration Date:

Dec 31, 2017

Type:

Pharmacist-in-Charge (V)

Bobby Joe Morris Jr.

License #:

PNT.041140 - Expired

Issued Date:

Oct 19, 1998

Expiration Date:

May 15, 2000

Type:

Pharmacy Intern

Bobby Joe Morris Jr.

License #:

PST.018512 - Active

Issued Date:

Aug 6, 2008

Expiration Date:

Dec 31, 2017

Type:

Pharmacist

Bobby L Morris

Phone:

(832)8676692

License #:

291683 - Expired

Category:

Apprentice Electrician

Expiration Date:

Jan 27, 2016

Bobby G Morris

License #:

19403 - Active

Category:

Dual Towing Operator(IM)/VSF Employee

Expiration Date:

Feb 10, 2018

Us Patents

-

Air Conditioner

view source -

US Patent:52953700, Mar 22, 1994

-

Filed:Nov 6, 1992

-

Appl. No.:7/972818

-

Inventors:Bobby D. Morris - Greer SC

-

International Classification:F25D 900

-

US Classification:62403

-

Abstract:An air conditioner comprises a compressing and expanding apparatus which includes a compressing system for compressing air taken into compression chambers in one of two cylinder blocks through an inlet aperture and discharging the air from an outlet aperture, and an expanding system for taking in the compressed air through an entrance aperture into expansion chambers in the other cylinder block and expanding the air therein. The air conditioner further comprises a heat exchanger for cooling positioned in the air flow between an outlet aperture of the compressing system and an entrance aperture of the expanding system. Since air is utilized as the cooling medium for the air conditioner, no air pollution or other problem is caused even if it is released into the atmosphere. Moreover, since multiple chambers are provided to process a large amount of air and since the compressing system and the expanding system are arranged compactly, the compressing and expanding apparatus can be compact.

-

Apparatus For Vapor Compression Distillation

view source -

US Patent:57728500, Jun 30, 1998

-

Filed:May 11, 1995

-

Appl. No.:8/439303

-

Inventors:Bobby D. Morris - Greer SC

-

International Classification:B01D 112

B01D 304 -

US Classification:202237

-

Abstract:A vapor compression distillation process and apparatus is provided wherein the apparatus includes a container having a generally vertical longitudinal center axis and bottom and top end caps, a plurality of generally vertical tubes spacedly disposed within the container, the tubes being fixedly held in position by opposing top and bottom tube sheets defining a condensing chamber therebetween wherein the condensing chamber has an upper, partially sectioned off chamber, an evaporation chamber within the container between the top tube sheet and a top end cap, a vapor compressor communicating with an upper area of the evaporation chamber and with the upper chamber of the condensing chamber, heat input communicating with the container, and a plurality of passages for passing a liquid into or out of the container. The process involves passing a liquid upwardly through the tubes, boiling the liquid to cause evaporation and create vapor, passing the vapor through a vapor compressor, passing the compressed vapor into the upper chamber of the condensing chamber and then to a remainder of the condensing chamber where condensation occurs and a distillate is formed. Movement of the tubes within the container provides a self-cleaning feature wherein scale build-up and potential is automatically reduced.

-

Process And Apparatus For Vapor Compression Distillation

view source -

US Patent:56456948, Jul 8, 1997

-

Filed:Mar 31, 1993

-

Appl. No.:8/040767

-

Inventors:James M. Stewart - Greenville SC

Bobby D. Morris - Greer SC -

Assignee:Vacom II, L.P. - Atlanta GA

-

International Classification:B01D 128

-

US Classification:203 22

-

Abstract:An improved vapor compression distillation process and apparatus are provided having a container with a substantially horizontal longitudinal center axis, two opposing end plates closing each end of the container, a first and second passage area defined within and on opposing ends of the container, each adjacent one of the end plates, a collecting chamber defined within the container between the first and second passage areas, a plurality of generally horizontal tubes spacedly exposed within the collecting chamber generally parallel to the longitudinal axis of the container, each of the tubes having two opposing ends which open into the first and second passage areas respectively, two opposing plates positioned on opposite ends of the horizontal tubes, each plate engaging similar ends of the horizontal tubes, a vapor compressor attached to the container such that the vapor compressor communicates with an upper area of the collecting chamber and communicates with the first passage area, at least one passage for passing a liquid into or out of the collecting chamber at a bottom thereof, and first and second conduits for passing a liquid into or out of the first and second passage areas at bottom areas thereof.

-

Process And Apparatus For Vapor Compression Distillation Using Plate And Frame Heat Exchanger

view source -

US Patent:58581774, Jan 12, 1999

-

Filed:Aug 7, 1996

-

Appl. No.:8/693421

-

Inventors:Bobby D. Morris - Greer SC

-

International Classification:B01D 300

-

US Classification:203 26

-

Abstract:An improved process and apparatus for vapor compression distillation is provided comprising a heat exchanger, a vapor compressor, and a liquid-vapor separator. The heat exchanger is preferably of the plate and frame type, with the plate faces being spaced apart to allow for the microscopic movement of the plates during the distillation process. This movement aids in the breaking off of hard scale which has accumulated on the plates. The process involves passing pressurized vapor and liquid into the heat exchanger, the pressurized vapor condensing to form a distillate, the liquid being heated to form a heated liquid and a non-pressurized vapor, the heated liquid and non-pressurized vapor being passed into a liquid-vapor separator where they are separated, the heated liquid being passed back into the heat exchanger and the non-pressurized vapor being passed into a vapor compressor for passage back into the heat exchanger.

Name / Title

Company / Classification

Phones & Addresses

CEO

Person 2 Person

Testing Laboratories

Testing Laboratories

651 Turner Rd, Glympville, SC 29126

Owner

VAPOR ENERGY, LLC

Mfg Service Industry Machinery

Mfg Service Industry Machinery

103 Lk Frst Dr, Greer, SC 29651

103 Lakeforest Dr, Greer, SC 29651

(864)8793305

103 Lakeforest Dr, Greer, SC 29651

(864)8793305

Director

T. G. COMMUNITY DEVELOPMENT CORPORATION

Wikipedia

Bob Morris (racing driver)

view sourceRobert Morris (born 4 October 1948) is an Australian former racing driver. Morris was one of the leading touring car drivers during the 1970s and continued ...

Plaxo

Bobby Morris

view sourceContractor at Sapphire Technologies

Bobby Morris

view sourceBoston

Robert W Morris Jr.

view source

Bobby J. Morris

view source

Bobby Morris

view source

Bobby Morris

view source

Bobby Morris

view sourceGoogleplus

Bobby Morris

Work:

McDonald's

Education:

Broome Community College - Communications & Media Arts

Bragging Rights:

Do i even have stuff to brag about

Bobby Morris

Work:

Kroger - Bagger (2006)

Bobby Morris

Work:

RETIRED

Bobby Morris

Work:

Valenti's Ristorante - General Manager

Bobby Morris

Bobby Morris

Bobby Morris

Bobby Morris

Youtube

Get Report for Bobby Don Morris from Greer, SC, age ~87