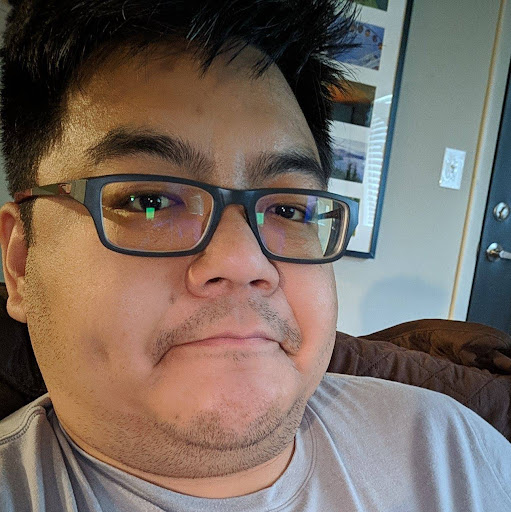

Kevin Ma

age ~53

from Diamond Bar, CA

- Also known as:

-

- Shaoxiang Ma

- Ma Shaoxiang

- Xiang Shao

- Shao A

Kevin Ma Phones & Addresses

- Diamond Bar, CA

- Pasadena, CA

- Corona, CA

- Eastvale, CA

Name / Title

Company / Classification

Phones & Addresses

Sales, Vice President

Vancouver Bullion & Currency Exchange Ltd

Foreign Currency Exchange Broker. Currency Exchange. Stamps For Collectors. Coin Dealers. Supplies. Etc.

Foreign Currency Exchange Broker. Currency Exchange. Stamps For Collectors. Coin Dealers. Supplies. Etc.

120 800 W Pender St, Vancouver, BC V6C 2V6

(604)6851008, (604)6857923

(604)6851008, (604)6857923

President

NRG MOTORTREND, INC

Ret Auto/Home Supplies

Ret Auto/Home Supplies

818 E Edna Pl, Covina, CA 91723

President

TIANYU, INC

9668 Milliken Ave #104-167, Rancho Cucamonga, CA 91730

10970 Arrow Rte, Rancho Cucamonga, CA 91730

10970 Arrow Rte, Rancho Cucamonga, CA 91730

Manager

M & L Farms, LLC

Sales, Vice President

Vancouver Bullion & Currency Exchange Ltd

Foreign Currency Exchange Broker · Currency Exchange · Stamps For Collectors · Coin Dealers · Supplies · Etc.

Foreign Currency Exchange Broker · Currency Exchange · Stamps For Collectors · Coin Dealers · Supplies · Etc.

(604)6851008, (604)6857923

President

Hi-Q Flooring LLC

Wholesale of Floor · Wholesale of Flooring · Business Services at Non-Commercial Site · Ret Floor Covering

Wholesale of Floor · Wholesale of Flooring · Business Services at Non-Commercial Site · Ret Floor Covering

1005 E Las Tunas Dr, San Gabriel, CA 91776

9133 Garvey Ave, Rosemead, CA 91770

9133 Garvey Ave, Rosemead, CA 91770

President

WULF WATCH CORPORATION

9668 Miliken Ave #104-167, Rancho Cucamonga, CA 91730

9668 Milliken Ave, Rancho Cucamonga, CA 91730

9446 Sunglow Ct, Rancho Cucamonga, CA 91730

9668 Milliken Ave, Rancho Cucamonga, CA 91730

9446 Sunglow Ct, Rancho Cucamonga, CA 91730

President

PASSION HEART PRODUCTION, INC

2421 S 3 Ave, Arcadia, CA 91006

Medicine Doctors

Kevin Ma

view sourceUs Patents

-

High Power, High Luminous Flux Light Emitting Diode And Method Of Making Same

view source -

US Patent:7193245, Mar 20, 2007

-

Filed:Jan 28, 2005

-

Appl. No.:11/044714

-

Inventors:Yongsheng Zhao - Monterey Park CA, US

William W. So - Walnut CA, US

Kevin Y. Ma - Arcadia CA, US

Chyi S. Chern - Arcadia CA, US

Heng Liu - Arcadia CA, US

Eugene J. Ruddy - Claremont CA, US -

Assignee:Lumei Optoelectronics Corporation - El Monte CA

-

International Classification:H01L 33/00

-

US Classification:257 91, 257 98, 257 99, 257100

-

Abstract:A high power, high luminous flux light emitting diode (LED) comprises a substrate, a light-emitting structure, a first electrode and a second electrode. The LED has a top surface layout design in which the first electrode has a number of legs extending in one direction, and the second electrode has a number of legs extending in the opposite direction. At least portions of the legs of the first electrode are interspersed with and spaced apart from portions of the legs of the second electrode. This provides a configuration that enhances current spreading along the length of the legs of both electrodes.

-

High Power, High Luminous Flux Light Emitting Diode And Method Of Making Same

view source -

US Patent:7642183, Jan 5, 2010

-

Filed:Jun 13, 2005

-

Appl. No.:11/150155

-

Inventors:Yongsheng Zhao - Monterey Park CA, US

William W. So - Walnut CA, US

Kevin Y. Ma - Arcadia CA, US

Chyi S. Chern - Arcadia CA, US

Heng Liu - Sunnyvale CA, US

Eugene J. Ruddy - Claremont CA, US -

Assignee:Dalian Meiming - Dalian

-

International Classification:H01L 33/00

-

US Classification:438609, 438 22, 257 91, 257 99

-

Abstract:A high power, high luminous flux light emitting diode (LED) comprises a substrate, a light-emitting structure, a first electrode and a second electrode. The LED has a top surface layout design in which the first electrode has a number of legs extending in one direction, and the second electrode has a number of legs extending in the opposite direction. At least portions of the legs of the first electrode are interspersed with and spaced apart from portions of the legs of the second electrode. This provides a configuration that enhances current spreading along the length of the legs of both electrodes.

-

Three-Dimensional Light-Emitting Devices And Method For Fabricating The Same

view source -

US Patent:8476652, Jul 2, 2013

-

Filed:Jul 30, 2010

-

Appl. No.:12/848053

-

Inventors:Chunhui Yan - El Monte CA, US

Jianping Zhang - El Monte CA, US

Ying Liu - El Monte CA, US

Fanghai Zhao - El Monte CA, US

Kevin Ma - El Monte CA, US -

Assignee:InvenLux Corporation - El Monte CA

-

International Classification:H01L 33/00

-

US Classification:257 89, 257 88, 257E33047

-

Abstract:A three-dimensional LED structure with vertically displaced active-region includes at least two groups of vertically displaced surfaces on a non-planar substrate. The first group of surfaces are separated from the second group of surfaces by a vertical distance in the growth direction of the LED structure. The first group of surfaces are connected to the second group of surfaces by sidewalls, respectively. The sidewalls can be inclined or vertical and have a sufficient height so that a layer such as an n-type layer, an active-region, or a p-type layer in a first LED structure deposited on the first group of surfaces and a corresponding layer such as an n-type layer, an active-region, or a p-type layer in a second LED structure deposited on the second group of surfaces are separated by the sidewalls. The two groups of surfaces may be vertically displaced from each other in certain areas of an LED chip, while merge into an integral surface in other areas. A method for fabricating the three-dimensional LED structure is also provided.

-

High Power, High Luminous Flux Light Emitting Diode And Method Of Making Same

view source -

US Patent:20030218176, Nov 27, 2003

-

Filed:May 24, 2002

-

Appl. No.:10/155001

-

Inventors:Yongsheng Zhao - Monterey Park CA, US

William So - Walnut CA, US

Kevin Ma - Arcadia CA, US

Chyi Chern - Arcadia CA, US

Heng Liu - Arcadia CA, US

Eugene Ruddy - Claremont CA, US -

International Classification:H01L027/15

-

US Classification:257/081000

-

Abstract:A high power, high luminous flux light emitting diode (LED) comprises a substrate, a light-emitting structure, a first electrode and a second electrode. The LED has a top surface layout design in which the first electrode has a number of legs extending in one direction, and the second electrode has a number of legs extending in the opposite direction. At least portions of the legs of the first electrode are interspersed with and spaced apart from portions of the legs of the second electrode. This provides a configuration that enhances current spreading along the length of the legs of both electrodes.

-

High Power, High Luminous Flux Light Emitting Diode And Method Of Making Same

view source -

US Patent:20040041160, Mar 4, 2004

-

Filed:Sep 4, 2003

-

Appl. No.:10/653995

-

Inventors:Yongsheng Zhao - Monterey Park CA, US

William So - Walnut CA, US

Kevin Ma - Arcadia CA, US

Chyi Chern - Arcadia CA, US

Heng Liu - Arcadia CA, US

Eugene Ruddy - Claremont CA, US -

International Classification:H01L027/15

H01L031/12

H01L033/00 -

US Classification:257/079000

-

Abstract:A high power, high luminous flux light emitting diode (LED) comprises a substrate, a light-emitting structure, a first electrode and a second electrode. The LED has a top surface layout design in which the first electrode has a number of legs extending in one direction, and the second electrode has a number of legs extending in the opposite direction. At least portions of the legs of the first electrode are interspersed with and spaced apart from portions of the legs of the second electrode. This provides a configuration that enhances current spreading along the length of the legs of both electrodes.

-

Implantable Materials

view source -

US Patent:20140242258, Aug 28, 2014

-

Filed:May 6, 2014

-

Appl. No.:14/271292

-

Inventors:- Irvine CA, US

Jordan Thompson - Chino Hills CA, US

Miram M. Abiad - Costa Mesa CA, US

Kevin A. Ma - Scotts Valley CA, US -

Assignee:Allergan, Inc. - Irvine CA

-

International Classification:A61L 27/00

-

US Classification:427 224

-

Abstract:A textured breast implant is provided which generally includes a fluid fillable elastomeric shell having a texture defined by struts, for example, hollow struts, defining interconnected open cells. Methods of making the texture include applying a silicone dispersion to a base material and removing the base material from the coating to form a silicone-based structure comprising struts defining interconnected open cells, said struts including internal surfaces defining cavities within the struts. The method may further include the step of contacting the silicone based structure having cavities with a silicone dispersion to cause the silicone to enter and fill the cavities.

-

Foam-Like Materials And Methods For Producing Same

view source -

US Patent:20140154491, Jun 5, 2014

-

Filed:Feb 6, 2014

-

Appl. No.:14/174111

-

Inventors:- Irvine CA, US

Jordan Thompson - Chino Hills CA, US

Miriam M. Abiad - Costa Mesa CA, US

Kevin Ma - Scotts Valley CA, US

Dennis Van Epps - Goleta CA, US

Nicholas J. Manesis - Escondido CA, US -

Assignee:ALLERGAN, INC. - Irvine CA

-

International Classification:C08J 9/26

-

US Classification:428220, 521 62, 264 49

-

Abstract:Described herein are foam-like materials having substantially the same physical structure of polyurethane foams but with properties that can be tailored for a particular application. Methods of forming these foam-like materials are also described.

Youtube

Plaxo

kevin ma

view sourceActfind com

Kevin Ma

view sourceHershey Foods

kevin ma

view sourceakpaint

Kevin Jinrong Ma

view source

Kevin Jun Ma

view source

Kevin H. Ma

view source

Kevin Ma

view source

Kevin Ma

view source

Kevin Ma

view source

Kevin Ma

view source

Kevin Angelo Ma

view sourceGoogleplus

Kevin Ma

Lived:

Houston, TX

Austin, TX

Los Angeles, CA

Torrence, CA

Taichung, Taiwan

Austin, TX

Los Angeles, CA

Torrence, CA

Taichung, Taiwan

Work:

University of Southern California

Education:

University of Southern California - Biomedical Engineering, University of Texas at Austin - Biomedical Engineering

Kevin Ma

Work:

The Gores Group - Senior Associate

Education:

Wharton School of the University of Pennsylvania - Finance, University of Pennsylvania - Electrical Engineering

Kevin Ma

Work:

All American Hardwood - Intern (2008-2009)

Platt Design Group - Intern (2007-2007)

Platt Design Group - Intern (2007-2007)

Education:

Purdue University - Business Management

Tagline:

"Do, or do not. There is no 'try'." - Yoda ('The Empire Strikes Back')

Kevin Ma

Work:

Amb productions - President

Myth clothing brand - Co-founder

Myth clothing brand - Co-founder

Tagline:

Ambition is a Myth

Kevin Ma

Education:

University of California, Irvine - Business Economics

Tagline:

Psalm 28:7 || The LORD is my strength and my shield; my heart trusts in him, and I am helped. My heart leaps for joy and I will give thanks to him in song.

Kevin Ma

Education:

Warren Mott High School

Tagline:

Asian, who likes making videos, watching tv/movies, and just chilling.

Kevin Ma

Education:

Town School

About:

I go to town school.

Tagline:

Cool guys don't look at explosions

Kevin Ma

Myspace

Classmates

Kevin Ma

view sourceSchools:

Bishop Noll Institute Hammond IN 1971-1975

Community:

Jerome Sliwa, Sylvia Planer

Kevin Ma

view sourceSchools:

Mark Keppel High School Alhambra CA 2000-2004

Community:

Alice Pitts, Olga Acevedo, Alfred Ruiz

Kevin Ma

view sourceSchools:

Valley Cottage Elementary School Valley Cottage NY 1989-1993

Community:

Skip Russell, Paul Duvall, Joan Galione, Joyce Carman

Kevin Ma

view sourceSchools:

Desert Vista High School Phoenix AZ 2005-2009

Kevin Ma

view sourceSchools:

Fairmont Elementary School Yorba Linda CA 1993-1995

Community:

Rani Friese, Deborah Jackson, Tracey Gulman

Kevin Ma

view sourceSchools:

Waldwick High School Waldwick NJ 2000-2004

Community:

Raymon Muniz, Ziad Majbour, Kristy Lombardi, A N, Gregory Weber, Theresa Romanek, Wade Dendy, Jennifer Walker, Miguel Cortez, Tania Alvarado, Justin Ajamian

Kevin Ma

view sourceSchools:

Cupertino Junior High School Sunnyvale CA 1981-1983

Kevin Ma

view sourceSchools:

Naperville North High School Naperville IL 2007-2011

Community:

Stephen Tam, Nada Azher, Kunal Patel, Katie Sahs, Frances Foley, Sarah Szczypkowski, Bob Boo, Hongliang Wang, Anthony Hasbun, Katherine Wang

Flickr

Get Report for Kevin Ma from Diamond Bar, CA, age ~53