Michael J Janicki

age ~58

from Salem, OR

- Also known as:

-

- Michael Joseph Janicki

- Mike Janicki

- Michael I

Michael Janicki Phones & Addresses

- Salem, OR

- Gresham, OR

- Portland, OR

- Gresham, OR

Us Patents

-

Electrochemical Treatment Of Integrated Circuit Substrates Using Concentric Anodes And Variable Field Shaping Elements

view source -

US Patent:6755954, Jun 29, 2004

-

Filed:Apr 4, 2002

-

Appl. No.:10/116077

-

Inventors:Steven T. Mayer - Lake Oswego OR

Timothy Patrick Cleary - Portland OR

Michael John Janicki - West Linn OR

Edmund B. Minshall - Sherwood OR

Thomas A. Ponnuswamy - Tulatin OR -

Assignee:Novellus Systems, Inc. - San Jose CA

-

International Classification:C25D 500

-

US Classification:205 96, 205123, 205125, 205157, 204224 R, 204DIG 7

-

Abstract:An apparatus for electrochemical treatment of a substrate, in particular for electroplating an integrated circuit wafer. An apparatus preferably includes dynamically operable concentric anodes and dielectric shields in an electrochemical bath. Preferably, the bath height of an electrochemical bath, the substrate height, and the shape and positions of an insert shield and a diffuser shield are dynamically variable during electrochemical treatment operations. Step include varying anode current, bath height and substrate height, shield shape, and shield position.

-

Sliding Tandem Media Feeder In A Printer

view source -

US Patent:8430391, Apr 30, 2013

-

Filed:Oct 13, 2011

-

Appl. No.:13/272996

-

Inventors:Daniel Clark Park - West Linn OR, US

Timothy Carlysle Shaw - Sammamish WA, US

Michael John Janicki - West Linn OR, US -

Assignee:Xerox Corporation - Norwalk CT

-

International Classification:B65H 3/44

-

US Classification:271 912, 271 902, 271 903, 271126

-

Abstract:In a tandem media supply, two vertical stacks of media sheets are stored. The first stack is positioned on a lift plate that rises as top sheets are removed from the stack of media. When the first stack is exhausted, the second stack is moved by an actuator towards a position where the lift plate was loaded with the first stack of media sheets. Movement of the second stack displaces a biased gate to decouple the lift plate from a drive member that elevated the lift plate. The lift plate drops under the effect of gravity to a position where the second stack of media sheets moves onto the lift plate. Once the second stack is on the lift plate, a biasing force returns the biased gate to a position that enables the drive member to elevate the lift plate.

-

Methods And Apparatus For Cleaning And Drying A Work Piece

view source -

US Patent:20050178402, Aug 18, 2005

-

Filed:Feb 12, 2004

-

Appl. No.:10/778799

-

Inventors:R. Stowell - Wilsonville OR, US

Tim Cleary - Portland OR, US

Michael Janicki - West Linn OR, US

Mark Dinneen - Portland OR, US -

International Classification:B08B003/02

-

US Classification:134001300, 134025400, 134033000, 134148000, 134153000, 134902000, 134186000, 134183000

-

Abstract:Methods and apparatus are provided for the cleaning and drying of a work piece. The apparatus comprises a carrier configured to carry a work piece that has a surface. The apparatus further comprises a press plate having a first surface and a second surface. During a cleaning process, the carrier, the press plate, or both, is configured to move relative to the other. The press plate is disposed a distance from the surface of the work piece such that, when a cleaning fluid is disposed between the work piece and the press plate, the surface tension of the cleaning fluid maintains a meniscus between the work piece and the press plate. A mega-sonic transducer is coupled to the second surface of the press plate.

-

Dynamic Sheath Control With Edge Ring Lift

view source -

US Patent:20230088715, Mar 23, 2023

-

Filed:Nov 29, 2022

-

Appl. No.:18/071192

-

Inventors:- Fremont CA, US

Richard M. Blank - San Jose CA, US

Curtis W. Bailey - West Linn OR, US

Michael J. Janicki - Portland OR, US -

International Classification:C23C 16/458

C23C 16/455 -

Abstract:A pedestal assembly including a pedestal for supporting a substrate. A central shaft positions the pedestal at a height during operation. A ring is placed along a periphery of the pedestal. A ring adjuster subassembly includes an adjuster flange disposed around a middle section of the central shaft. The subassembly includes a sleeve connected to the adjuster flange and extending from the adjuster flange to an adjuster plate disposed under the pedestal. The subassembly includes ring adjuster pins connected to the adjuster plate and extending vertically from the adjuster plate. Each of the ring adjuster pins being positioned on the adjuster plate at locations adjacent to and outside of a pedestal diameter. The ring adjuster pins contacting an edge undersurface of the ring. The adjuster flange coupled to at least three adjuster actuators for defining an elevation and tilt of the ring relative to a top surface of the pedestal.

-

Dynamic Sheath Control With Edge Ring Lift

view source -

US Patent:20200173018, Jun 4, 2020

-

Filed:Nov 29, 2018

-

Appl. No.:16/205028

-

Inventors:- Fremont CA, US

Richard M. Blank - San Jose CA, US

Curtis W. Bailey - West Linn OR, US

Michael J. Janicki - Portland OR, US -

International Classification:C23C 16/458

C23C 16/455 -

Abstract:A pedestal assembly including a pedestal for supporting a substrate. A central shaft positions the pedestal at a height during operation. A ring is placed along a periphery of the pedestal. A ring adjuster subassembly includes an adjuster flange disposed around a middle section of the central shaft. The subassembly includes a sleeve connected to the adjuster flange and extending from the adjuster flange to an adjuster plate disposed under the pedestal. The subassembly includes ring adjuster pins connected to the adjuster plate and extending vertically from the adjuster plate. Each of the ring adjuster pins being positioned on the adjuster plate at locations adjacent to and outside of a pedestal diameter. The ring adjuster pins contacting an edge undersurface of the ring. The adjuster flange coupled to at least three adjuster actuators for defining an elevation and tilt of the ring relative to a top surface of the pedestal.

-

Lift Pin Assembly And Associated Methods

view source -

US Patent:20170133260, May 11, 2017

-

Filed:Dec 21, 2015

-

Appl. No.:14/977554

-

Inventors:- Fremont CA, US

Jeffrey Womack - Lake Oswego OR, US

Lisa Marie Gytri - Sherwood OR, US

Michael J. Janicki - West Linn OR, US -

International Classification:H01L 21/687

-

Abstract:A substrate lift pin assembly includes a tubular support member connected to a bottom of a pedestal beneath a lift pin through-hole. The tubular support member has an interior cavity and an end closure with a cartridge through-hole extending through the end closure. A cartridge member includes a lift pin holder portion and a plunger portion. The lift pin holder portion is located inside of the interior cavity of the tubular support member. The plunger portion extends through the cartridge through-hole of the end closure of the tubular support member. A lift pin extends through the lift pin through-hole and connects to the lift pin holder portion of the cartridge member. A handle member connects to the plunger portion of the cartridge member at a location near a distal end of the plunger portion relative to the tubular support member. The handle member is configured to engage a lifting mechanism.

Resumes

Michael Janicki

view sourceLocation:

United States

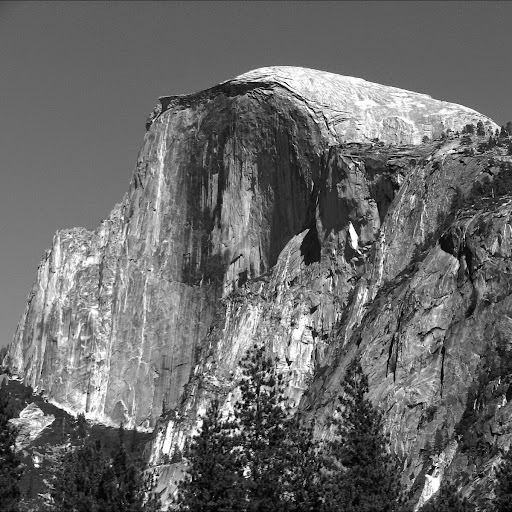

Flickr

Michael Janicki

view source

Michael Janicki

view source

Michael Janicki

view source

Michael Janicki

view source

Michael Janicki

view source

Michael Janicki

view source

Michael Janicki

view source

Michael Janicki

view sourceClassmates

Michael Janicki

view sourceSchools:

Vocational Technical School Providence RI 1967-1971

Community:

Richard Drainville, Dollard Lavallee, Robert Armstrong, Frank Bourgeois, Don Post, Paul Greene, Michael Maxson, Don Lacroix, Donald Lamarre, David Dias, Carl Cofone

Michael Janicki | Pace Un...

view source

Vocational Technical Scho...

view sourceGraduates:

Gerald Halleck (1960-1964),

Michael Janicki (1967-1971),

Robert Beaudreau (1960-1964),

Dennis Desrosiers (1966-1970)

Michael Janicki (1967-1971),

Robert Beaudreau (1960-1964),

Dennis Desrosiers (1966-1970)

Mills High School, Burlin...

view sourceGraduates:

Mike Janicki (1985-1989),

Ray Marks (1986-1990),

Carol Gerasimovich (1983-1987),

Michael Lanzrath (2002-2006)

Ray Marks (1986-1990),

Carol Gerasimovich (1983-1987),

Michael Lanzrath (2002-2006)

Pace University - Busines...

view sourceGraduates:

Michael Janicki (1970-1974),

Anthony Vozzolo (1997-2001),

Richard Mann (1972-1974),

Jahanara Huma Siddiqui (2001-2005)

Anthony Vozzolo (1997-2001),

Richard Mann (1972-1974),

Jahanara Huma Siddiqui (2001-2005)

Mylife

Michael Janicki Dundalk ...

view sourceView Michael Janicki's profile. Use our people search engine to find old friends like Michael at MyLife.

Youtube

Googleplus

Michael Janicki

Education:

Herzing College- Minneapolis Drafting School - Architectural CAD Drafting

About:

Catholic, athlete, Pittsburgh Penguins, Steelers and Pirates fan. AutoCAD Technician, and avid outdoor enthusiast in camping, photography, biking, kayak and hiking.

Tagline:

Christian, Sports enthusiast, Outdoors enthusiast, AutoCAD Draftsman

Michael Janicki

Education:

University of Minnesota - BS Architecture, University of Minnesota - BA Urban Studies

About:

Hi, What to say about myself? You'll just have to meet me!

Michael Janicki

Michael Janicki

Michael Janicki

Myspace

Get Report for Michael J Janicki from Salem, OR, age ~58

![Best of A. Schwarzman [The Legends] Best of A. Schwarzman [The Legends]](https://i.ytimg.com/vi/tcPlY3P0cQg/hq720.jpg?sqp=-oaymwEcCNAFEJQDSFXyq4qpAw4IARUAAIhCGAFwAcABBg==&rs=AOn4CLD3KlmpQlSck37vgy7YtuxF5G5uSA)