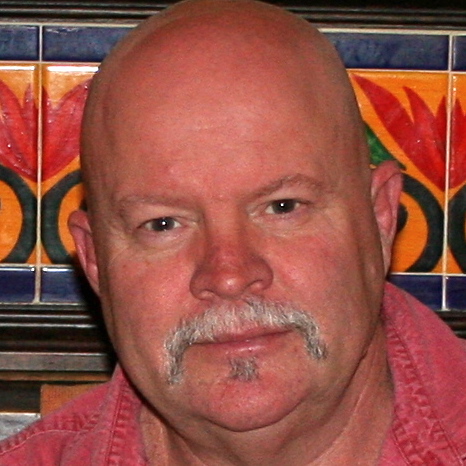

Grant Edward Cooley

age ~57

from Gulfport, MS

- Also known as:

-

- Grant E Cooley

- Grant Leleza Cooley

- Grant C Cooley

- George E Cooley

- Edward Cooley Grant

- Ge Cooley

Grant Cooley Phones & Addresses

- Gulfport, MS

- Hattiesburg, MS

- Petal, MS

- Warren, MI

- Laurel, MS

- Novi, MI

- Purvis, MS

- Harrisburg, PA

Work

-

Company:Echostar satellite l.l.cJul 2007

-

Position:Quality assurance specialist

Education

-

School / High School:University of Southern Mississippi- Hattiesburg, MSDec 1996

-

Specialities:Bachelor of Science in Polymer Science

Skills

RMS - 800 RTV Molding Equipment Brabende... • manufacturing and testing equipment

Resumes

Remote Qas At Echostar Satellite Llc

view sourceLocation:

Hattiesburg, Mississippi Area

Industry:

Broadcast Media

Technical Sales Representative

view sourceLocation:

Biloxi, MS

Industry:

Plastics

Work:

Echostar Satellite LLC since Jul 2007

Remote Quality Assurance Specialist

Self Employed Sep 2005 - Mar 2007

Independent Polymer Consultant

University of Southern Mississippi - MS Polymer Institute Sep 2003 - Aug 2005

Project Manager and Research Associate

BASF 2001 - 2003

Development Chemist

Protech Powder Coatings Dec 1999 - Dec 2000

Technical Sales/Service Representative

Remote Quality Assurance Specialist

Self Employed Sep 2005 - Mar 2007

Independent Polymer Consultant

University of Southern Mississippi - MS Polymer Institute Sep 2003 - Aug 2005

Project Manager and Research Associate

BASF 2001 - 2003

Development Chemist

Protech Powder Coatings Dec 1999 - Dec 2000

Technical Sales/Service Representative

Education:

University of Southern Mississippi 1990 - 1995

BS, Polymer Science

BS, Polymer Science

Skills:

Materials

Polymers

Adhesives

Injection Molding

Coatings

Resin

R&D

Extrusion

Quality Assurance

Chemistry

Surfactants

Manufacturing

Polymer Science

Plastics

Account Management

Design of Experiments

Process Engineering

Six Sigma

Polymer Characterization

Powder Coating

Polymer Composites

Quality Management

Plastic Extrusion

Technical Product Sales

Analytical Skills

Coatings Technology

Computer Proficiency

Social Skills

Experimental Design

Biodegradable Polymers

Quantitative Research

Rapid Prototyping

Industrial Coatings

Technical Support

Creative Problem Solving

Polymers

Adhesives

Injection Molding

Coatings

Resin

R&D

Extrusion

Quality Assurance

Chemistry

Surfactants

Manufacturing

Polymer Science

Plastics

Account Management

Design of Experiments

Process Engineering

Six Sigma

Polymer Characterization

Powder Coating

Polymer Composites

Quality Management

Plastic Extrusion

Technical Product Sales

Analytical Skills

Coatings Technology

Computer Proficiency

Social Skills

Experimental Design

Biodegradable Polymers

Quantitative Research

Rapid Prototyping

Industrial Coatings

Technical Support

Creative Problem Solving

Creative Art Director

view sourceWork:

Creative Art Director

Grant Cooley

view sourceSkills:

Lifestyle

Ebay

Ebay

Grant Cooley Gulfport, MS

view sourceWork:

EchoStar Satellite L.L.C

Jul 2007 to 2000

Quality Assurance Specialist Independent Polymer Consultant

Sep 2005 to Jun 2007 Mississippi Polymer Institute

Sep 2003 to Aug 2005

Project Manager BASF Corporation

Jan 2001 to Aug 2003

Development Chemist I Protech Powder Coatings

New York, NY

Dec 1999 to Nov 2000

Technical Sales Representative USM - Dr. Robert Y. Lochhead

Sep 1998 to Nov 1999

Research Associate - Safety Director Herberts Powder Coatings

Nov 1997 to May 1998

Technical Sales/Service Engineer Mississippi Polymer Institute and Pilot Manufacturing Extension Center

Jun 1996 to Oct 1997

Polymer Technician Mississippi Air National Guard

Jun 1989 to Jun 1994 University of Southern Mississippi

Sep 1993 to Dec 1993

Research Associate University of Southern Mississippi

Jul 1991 to May 1992

Research Associate - Safety coordinator

Jul 2007 to 2000

Quality Assurance Specialist Independent Polymer Consultant

Sep 2005 to Jun 2007 Mississippi Polymer Institute

Sep 2003 to Aug 2005

Project Manager BASF Corporation

Jan 2001 to Aug 2003

Development Chemist I Protech Powder Coatings

New York, NY

Dec 1999 to Nov 2000

Technical Sales Representative USM - Dr. Robert Y. Lochhead

Sep 1998 to Nov 1999

Research Associate - Safety Director Herberts Powder Coatings

Nov 1997 to May 1998

Technical Sales/Service Engineer Mississippi Polymer Institute and Pilot Manufacturing Extension Center

Jun 1996 to Oct 1997

Polymer Technician Mississippi Air National Guard

Jun 1989 to Jun 1994 University of Southern Mississippi

Sep 1993 to Dec 1993

Research Associate University of Southern Mississippi

Jul 1991 to May 1992

Research Associate - Safety coordinator

Education:

University of Southern Mississippi

Hattiesburg, MS

Dec 1996

Bachelor of Science in Polymer Science

Hattiesburg, MS

Dec 1996

Bachelor of Science in Polymer Science

Skills:

RMS - 800 RTV Molding Equipment Brabender Extruder FTIR Injection Molding Machine ESEM DSC Brookfield/Stormer Viscometers Optical Microscopes Microtrac Twin/Single Screw Extruder Beckman pH Meter Max 2000 Instron Tensile Tester ISO 9000 Powder coating application, manufacturing and testing equipment

Us Patents

-

Aqueous Dispersions And Aqueous Electrodepositable Primers

view source -

US Patent:7314900, Jan 1, 2008

-

Filed:Nov 16, 2001

-

Appl. No.:09/987822

-

Inventors:Charles L. Tazzia - Grosse Pointe Farms MI, US

Robert D. Schiller - Northville MI, US

William H. Alford - Livonia MI, US

Grant E. Cooley - Warren MI, US -

Assignee:BASF Corporation - Southfield MI

-

International Classification:C08G 18/08

-

US Classification:524800, 524591, 524599, 524612, 524832, 524839

-

Abstract:The invention relates to aqueous dispersions and aqueous electrodepositable primers made with the aqueous dispersions of the invention. The aqueous dispersion of the invention requires the use of a polymer (a) comprising one or more water dispersible groups per molecule and one or more functional groups (f), and at least one crosslinking agent (b) comprising one or more blocked functional groups (f) reactive with polymer (a) after unblocking. Crosslinking agent (b) has a Tof from 40 to 70 C. /105 to 158 F. and is a solid at 23. 9 C. /75 F. when at 100% by weight solids. Crosslinking agent (b) is melt mixed into acrylic polymer (a) to provide a first dispersion and said first dispersion is emulsified in water to provide an aqueous dispersion. In a preferred embodiment, the aqueous electrodepositable primers comprise at least 50% by weight water and an acrylic polymer (a) having one or more salted sites per molecule.

-

An Improved Method For Making An Aqueous Dispersion

view source -

US Patent:20030096906, May 22, 2003

-

Filed:Nov 16, 2001

-

Appl. No.:09/987823

-

Inventors:Charles Tazzia - Grosse Pointe Farms MI, US

William Alford - Livonia MI, US

Grant Cooley - Warren MI, US -

International Classification:C08K003/00

-

US Classification:524/800000

-

Abstract:The invention relates to a method for preparing aqueous dispersions, especially electrodepositable aqueous dispersions. The invention requires the use of a polymer (a) comprising one or more water dispersible groups per molecule and one or more functional groups (f), and at least one crosslinking agent (b) comprising one or more blocked functional groups (f) reactive with polymer (a) after unblocking. Crosslinking agent (b) has a Tof from 40 to 70 C./105 to 158 F. and is a solid at 23.9 C./75 F. when at 100% by weight solids. Crosslinking agent (b) is mixed into polymer (a) at a temperature at or above the melting temperatures of both polymer (a) and compound (b) but below the temperature at which blocked functional groups (f) unblock. Sufficient water is added to the resulting melt-mixture (ii) to provide an aqueous dispersion.

Classmates

Gerry Cooley, Grant High ...

view source

Grant Cooley

view source

Grant Cooley

view source

Grant Cooley

view source

Grant Cooley

view source

Grant Cooley

view source

Grant Cooley

view source

Grant Cooley

view source

Grant Cooley

view sourceMyspace

Youtube

Googleplus

Grant Cooley

Work:

Synergetics USA - Manufacturing Engineering Intern (7)

Education:

Missouri University of Science and Technology - Mechanical Engineering

Grant Cooley

Grant Cooley

Grant Cooley

Grant Cooley

Flickr

Get Report for Grant Edward Cooley from Gulfport, MS, age ~57