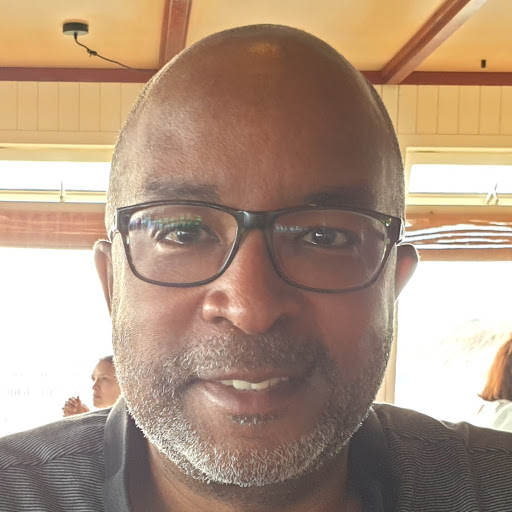

Brian Paul Reeves

age ~42

from Edmond, OK

- Also known as:

-

- Brian P Reeves

- James Reeves

- Brian Tullier

- James Palesano

- Phone and address:

-

2309 Tredington Way, Edmond, OK 73034

(405)2052729

Brian Reeves Phones & Addresses

- 2309 Tredington Way, Edmond, OK 73034 • (405)2052729

- 1124 Mcgee Dr, Norman, OK 73069 • (405)7010886

- 1915 Riverside Dr, Norman, OK 73072 • (405)7018255

- 1124 Mcgee Dr, Norman, OK 73069 • (405)9213916

Work

-

Company:Intel (aepona), dallas2010

-

Position:Business/functional analyst

Education

-

School / High School:LOUISIANA TECH UNIVERSITY- Ruston, LA2000

-

Specialities:Bachelor of Science in Computer Information Systems

Us Patents

-

Seal Section With Parallel Bag Sections

view source -

US Patent:20130240199, Sep 19, 2013

-

Filed:Mar 19, 2012

-

Appl. No.:13/424191

-

Inventors:Alan Howell - Oklahoma City OK, US

Chengbao Wang - Oklahoma City OK, US

Brian Reeves - Edmond OK, US -

Assignee:GE OIL & GAS ESP, INC. - Oklahoma City OK

-

International Classification:E21B 43/00

-

US Classification:166106, 166105

-

Abstract:A downhole pumping system includes a motor, a pump driven by the motor and a seal section positioned between the pump and the motor. The seal section preferably includes a first seal bag assembly, a second seal bag assembly and an interconnect module connected between the first seal bag assembly and the second seal bag assembly. The interconnect module includes a plenum, at least one fluid exchange passage connected to the plenum, and a shaft seal assembly. The shaft seal assembly is configured to divert fluid from the plenum into the at least one fluid exchange passage. In another aspect, a first group of interconnect modules within the seal section each includes a shaft seal assembly oriented in a first direction and a second group of the interconnect modules each includes a shaft seal assembly oriented in a second direction to selectively apply an axial force on the shaft.

-

Systems And Methods For Wireless Power Transmission In A Well

view source -

US Patent:20200362672, Nov 19, 2020

-

Filed:May 8, 2020

-

Appl. No.:16/870655

-

Inventors:- Houston TX, US

Yi Liao - Edmond OK, US

Thomas McClain Scott - Cypress TX, US

Alexey Tyshko - Oklahoma City OK, US

Virginia Howe - Oklahoma City OK, US

Brian Reeves - Edmond OK, US -

International Classification:E21B 41/00

E21B 43/12

E21B 17/00

E21B 17/02

E21B 47/12

E21B 47/00

E21B 47/26 -

Abstract:Systems and methods for wireless power transmission in a well, wherein first and second structural members of a well completion are electrically connected to form an electrical circuit, with first and second toroidal transformers positioned around the second structural member at different axial locations. A power source coupled to the first toroidal transformer is configured to generate an output voltage which is applied to the first toroidal transformer, inducing a corresponding electrical current in the electrical circuit. This in turn induces a second voltage on the second toroidal transformer, which is provided to a downhole tool. The tool may include conditioning circuitry, which rectifies the received power and charges a battery. The downhole electric tool is then operated using the received power.

-

Systems And Methods For Wireless Communication In A Well

view source -

US Patent:20200362691, Nov 19, 2020

-

Filed:May 8, 2020

-

Appl. No.:16/870651

-

Inventors:- Houston TX, US

Yi Liao - Edmond OK, US

Thomas McClain Scott - Cypress TX, US

Alexey Tyshko - Oklahoma City OK, US

Virginia Howe - Oklahoma City OK, US

Brian Reeves - Edmond OK, US -

International Classification:E21B 47/13

E21B 47/12

E21B 41/00

E21B 47/07 -

Abstract:Systems and methods for communicating between surface equipment and a downhole tool installed in a well. First and second toroidal transformers are positioned around an inner one of a pair of coaxial structural members of a well completion (e.g., a pump rod and tubular, or a tubular and a well casing) which are electrically coupled to form an electrical circuit. A transmitter generates a data signal which is applied to the first toroidal transformer, causing a corresponding electrical current to be induced in the circuit, which then induces the data signal on the second toroidal transformer. A receiver coupled to the second toroidal transformer receives the data signal induced on the second toroidal transformer. The transmitter and receiver may be components of transceivers that may communicate bidirectionally. Additional toroidal coils and transceiver may be provided to communicate with equipment at additional locations in the well.

-

Artificial Lift System For A Resource Exploration And Recovery System

view source -

US Patent:20200256171, Aug 13, 2020

-

Filed:Feb 12, 2019

-

Appl. No.:16/273824

-

Inventors:Jeremy Daniel VanDam - W. Coxsackie NY, US

Brian Reeves - Edmond OK, US -

Assignee:Baker Hughes Oilfield Operations LLC - Houston TX

-

International Classification:E21B 43/12

E21B 21/08

E21B 33/12 -

Abstract:An artificial lift system including a tubular extending into a wellbore. The tubular includes a first end arranged at a surface of a formation, a second end terminating in the wellbore, and an intermediate portion. The intermediate portion includes a plurality of gas lift valves. A jet pump is fluidically connected to the second end of the tubular. A liquid supply conduit includes a terminal end arranged at the first end of the tubular and a gas supply conduit includes a terminal end portion arranged at the first end of the tubular.

-

Surface-Based Separation Assembly For Use In Separating Fluid

view source -

US Patent:20180334895, Nov 22, 2018

-

Filed:May 16, 2017

-

Appl. No.:15/596448

-

Inventors:- Schenectady NY, US

Catherine James - Oklahoma City OK, US

Chengbao Wang - Oklahoma City OK, US

Brian Paul Reeves - Edmond OK, US

Michael Salerno - Edmond OK, US

Shyam Sivaramakrishnan - Fremont CA, US -

International Classification:E21B 43/34

B01D 19/00

B01D 17/02

C02F 1/20

C02F 1/38 -

Abstract:A surface-based separation assembly for use in separating fluid. The surface-based separation assembly includes a gas-liquid separator configured to receive a fluid stream, and configured to separate the fluid stream into a gas stream and a mixed stream of at least two liquids. A liquid-liquid separator is in flow communication with the gas-liquid separator. The liquid-liquid separator is configured to receive the mixed stream from the gas-liquid separator, and is configured to separate the mixed stream into a first liquid stream and a second liquid stream. The assembly further includes a rotatable shaft including a first portion extending through the gas-liquid separator, and a second portion extending through the liquid-liquid separator. The rotatable shaft is configured to induce actuation of the gas-liquid separator and the liquid-liquid separator.

-

Wireline-Deployed Esp With Self-Supporting Cable

view source -

US Patent:20180283384, Oct 4, 2018

-

Filed:Mar 28, 2018

-

Appl. No.:15/939126

-

Inventors:- Houston TX, US

Ameen Malkawi - Dhahran, SA

Brian Reeves - Edmond OK, US

Michael Hughes - Oklahoma City OK, US

Victor Acacio - Oklahoma City OK, US

John Mack - Claremore OK, US -

International Classification:F04D 13/08

F04D 13/06

F04D 13/02 -

Abstract:A submersible pumping system for use in producing wellbore fluids from a wellbore within a subterranean formation includes a motor and a pump driven by the motor to produce the wellbore fluids. The pumping system further includes a self-supporting power cable connected to the pump. The self-supporting power cable includes a plurality of conductors and a plurality of strength members. A method of deploying and retrieving a submersible pumping system in a wellbore includes the steps of connecting a wireline to the submersible pumping system, connecting a self-supporting power cable to the submersible pumping system, lowering the submersible pumping system into the wellbore while the weight of the submersible pumping system is borne by the wireline. The method continues with the step of locating the submersible pumping system on a landing assembly, disconnecting the wireline from the submersible pumping system, and retrieving the wireline from the wellbore without removing the submersible pumping system from the wellbore.

-

Hydraulic Actuator With Pressure-Based Piston Position Feedback

view source -

US Patent:20180209413, Jul 26, 2018

-

Filed:Jan 25, 2017

-

Appl. No.:15/415582

-

Inventors:- Schenectady NY, US

Christopher Martin Middleton - Norman OK, US

Brian Paul Reeves - Edmond OK, US

Deepak Trivedi - Halfmoon NY, US -

International Classification:F04B 47/08

F04B 49/00

F04B 49/22

F04B 53/10

F04B 53/16

F04B 53/14

E21B 43/12 -

Abstract:A hydraulic actuator includes a piston housing having a head end and a base end opposite the head end and a drive piston movable between a first piston position proximate to the head end and a second piston position proximate to the base end. The hydraulic actuator further includes a control valve positionable between a first control valve position, in which the control valve directs fluid into the base end, and a second control valve position, in which the control valve directs fluid into the head end. A pressure-based position feedback system configured to facilitate transition of the control valve between the first control valve position and the second control valve position in response to predetermined head end and base end pressures.

-

Sensorless Manifold Assembly With Pressure-Based Reversing Fluid Circuit

view source -

US Patent:20180202241, Jul 19, 2018

-

Filed:Jan 18, 2017

-

Appl. No.:15/409337

-

Inventors:- Schenectady NY, US

Aaron Christopher Noakes - Norman OK, US

Brian Paul Reeves - Edmond OK, US -

International Classification:E21B 17/18

E21B 43/12

E21B 34/10 -

Abstract:A downhole manifold assembly includes a manifold body defining a longitudinal axis and having a first end face, a second end face, and an outer surface extending therebetween. A fluid circuit is defined in the manifold body and includes a plurality of axially extending fluid passages and a plurality of radially extending fluid passages. The radially extending fluid passages extend to the outer surface of the manifold body. Each radially extending fluid passage defines a respective aperture in the outer surface. The manifold assembly also includes a control valve coupled to the manifold body. The control valve is positionable between a first position in which a flow of pressurized fluid is channeled through the fluid circuit in a first direction, and a second position in which the flow is reversed and the pressurized fluid is channeled through the fluid circuit in a second direction.

Resumes

Brian Reeves

view source

Brian Reeves

view source

Brian Reeves

view source

Radiology Technologist Iv

view sourceWork:

Radiology Technologist Iv

Brian Reeves

view sourceLocation:

United States

Brian Reeves

view sourceLocation:

United States

Graduate From Brandeis University

view sourceLocation:

Washington, District Of Columbia

Industry:

International Affairs

Work:

B'Tselem USA Jun 2011 - Sep 2011

Community Outreach Associate

American Jewish Committee Jun 2011 - Aug 2011

Internship

Institute for Counter-Terrorism Jun 2009 - Jul 2009

Research Intern

Community Outreach Associate

American Jewish Committee Jun 2011 - Aug 2011

Internship

Institute for Counter-Terrorism Jun 2009 - Jul 2009

Research Intern

Education:

Brandeis University 2008 - 2011

Bachelor of Arts, Islamic & Middle Eastern Studies

Bachelor of Arts, Islamic & Middle Eastern Studies

Brian Reeves

view sourceLocation:

United States

Medicine Doctors

Brian E. Reeves

view sourceSpecialties:

Diagnostic Radiology

Work:

Radiology Specialists Of Florida

601 E Rollins St, Orlando, FL 32803

(407)3031944 (phone), (407)2004947 (fax)

601 E Rollins St, Orlando, FL 32803

(407)3031944 (phone), (407)2004947 (fax)

Education:

Medical School

Nova Southeastern University College of Osteopathic Medicine

Graduated: 1998

Nova Southeastern University College of Osteopathic Medicine

Graduated: 1998

Procedures:

Arthrocentesis

Lumbar Puncture

Lumbar Puncture

Languages:

English

Description:

Dr. Reeves graduated from the Nova Southeastern University College of Osteopathic Medicine in 1998. He works in Orlando, FL and specializes in Diagnostic Radiology. Dr. Reeves is affiliated with Florida Hospital Flagler and Florida Hospital Orlando.

Name / Title

Company / Classification

Phones & Addresses

Middle Tennessee Market President

Capital Bank

Banks

Banks

231 S Royal Oaks Blvd, 2nd Floor, Franklin, TN 37064-8965

(615)7944944

(615)7944944

Supervisor Prov

Dobson Cellular Systems, LLC

Radiotelephone Communications

Radiotelephone Communications

14201 Wireless Way, Oklahoma City, OK 73134

L & B ENTERPRISES, LLC

REEVES CONTRACTING, LTD

ADVANCED INVESTIGATIONS AND SOLUTIONS, INC

Plaxo

Brian Reeves

view sourceDayton, OhioPast: Workflow Mgr. / Sr.Graphic Designer at ESKCO, INC. I am a Freelance Graphic Designer based in Dayton, Ohio.

Brian Reeves

view sourceNoblesville, INPresident at Hamilton Financial Group

Brian Reeves

view sourceGlen Ellen, CAVice President - Sales at Benziger Family Winery

Brian Reeves

view sourceCEO at Avvio

Flickr

Brian D. Reeves

view source

Brian Nobby Reeves

view source

Jared Brian Reeves

view source

Brian Matthew Reeves

view source

Brian A Reeves

view source

Brian Ed Reeves

view source

Brian Reeves

view source

Brian Reeves

view sourceClassmates

Brian Reeves

view sourceSchools:

Pontiac Northern High School Pontiac MI 1974-1978

Community:

Lynn Williams

Brian Reeves

view sourceSchools:

Nelson Elementary School Burnaby Saudi Arabia 1968-1974, Mcpherson Park High School Burnaby Saudi Arabia 1974-1978, Hugh Boyd Junior High School Richmond Saudi Arabia 1976-1978, Station Stretch School Richmond Saudi Arabia 1978-1980

Community:

Cristine Lightheart, Coreen Dempsey, Helen Howatt, Ian Mcleod, Kim Farmer

Brian Reeves

view sourceSchools:

Franklin Elementary School Wadsworth OH 1978-1983

Community:

Joseph Pniewski

Brian Reeves

view sourceSchools:

Nechako Valley High School Vanderhoof Saudi Arabia 1965-1970

Community:

Laurel Warkentin, James Rossetti, Dustin Woodruff, Julie Walker, George Lipke

Brian Reeves

view sourceSchools:

Samson High School Samson AL 1994-1998

Community:

Rodney Brown, Eva Gant

Brian Reeves

view sourceSchools:

Reeves High School Longview LA 1980-1984

Brian Reeves

view sourceSchools:

Ben Davis Ninth Grade Center Indianapolis IN 2007-2011

Community:

Ron Thompson

Googleplus

Brian Reeves

Work:

Ventnor City - Low man

Education:

Absegami High School

Brian Reeves

Education:

Brandeis University - Islamic and Middle Eastern Studies; International and Global Studies

Brian Reeves

Work:

Freelancer - Web designer and developer (2006)

Brian Reeves

Work:

Nexus Mediation - Mediator

Brian Reeves

Brian Reeves

Brian Reeves

Brian Reeves

Youtube

Get Report for Brian Paul Reeves from Edmond, OK, age ~42