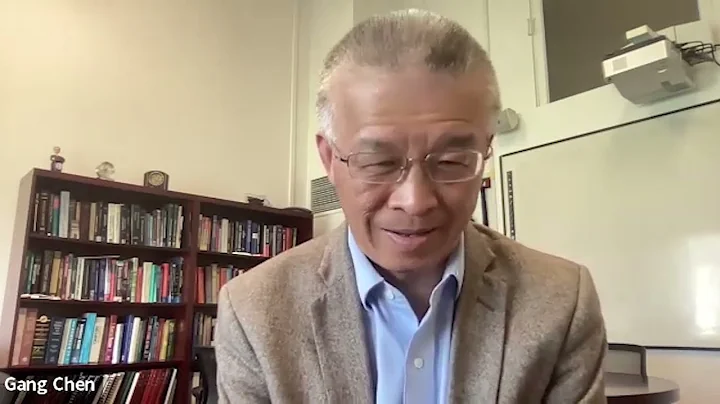

Chenggang G Chen

age ~58

from Beavercreek, OH

- Also known as:

-

- Cheeng Chen

- Gang Chen Cheeng

- Chen Chenggang

- Phone and address:

-

3760 Mesquite Dr, Dayton, OH 45440

(937)4272632

Chenggang Chen Phones & Addresses

- 3760 Mesquite Dr, Dayton, OH 45440 • (937)4272632

- 3880 Chalet Cir, Dayton, OH 45431

- Beavercreek, OH

- Evanston, IL

- Cleveland, OH

- Shaker Hts, OH

- 3760 Mesquite Dr, Beavercreek, OH 45440

Work

-

Company:Air force research laboratoryJan 2000

-

Position:Senior scientist

Education

-

Degree:Doctorates, Doctor of Philosophy

-

School / High School:Case Western Reserve University1993 to 1998

-

Specialities:Philosophy, Chemistry

Skills

Molecular Biology • Simulations • Data Analysis • Spectroscopy • Program Management • Biochemistry • Materials • R&D • Materials Science • Characterization • Nanotechnology

Interests

Science and Technology

Industries

Research

Us Patents

-

Method Of Forming Nanocomposite Materials

view source -

US Patent:20050245665, Nov 3, 2005

-

Filed:May 23, 2005

-

Appl. No.:11/134886

-

Inventors:Chenggang Chen - Beavercreek OH, US

-

International Classification:C08K003/34

-

US Classification:524493000

-

Abstract:A method of making a nanocomposite having homogeneously dispersed individual nanosize spherical silica particles. The invention also involves a method of making a nancomposite having homogeneously dispersed small aggregated nanosize spherical silica particles.

-

Method Of Forming Nanocomposite Materials

view source -

US Patent:20050272847, Dec 8, 2005

-

Filed:May 23, 2005

-

Appl. No.:11/134937

-

Inventors:Chyi-Shan Wang - Beavercreek OH, US

Max Alexander - Centerville OH, US

Chenggang Chen - Beavercreek OH, US -

International Classification:C08K003/34

-

US Classification:524442000, 524492000

-

Abstract:A method of making a polymeric nanocomposite material. The method includes combining nanosize materials, such as layered silicates, or nanosize sphered silica, with a polymer and a solvent to form a substantially homogeneous mixture, followed by removal of the solvent. The method forms a layered-silicate nanocomposite with an intercalated nanostructure with very large interplanar spacing or a combination of intercalated and exfoliated nanostructure.

-

Method Of Forming Nanocomposite Materials

view source -

US Patent:20060079623, Apr 13, 2006

-

Filed:May 23, 2005

-

Appl. No.:11/135091

-

Inventors:Chenggang Chen - Beavercreek OH, US

-

International Classification:C08K 9/04

-

US Classification:524445000

-

Abstract:A method of making a polymeric nanocomposite material. The method includes combining nanosize materials, such as layered silicates, or tube-silicates, with a thermosetting polymer and a solvent to form a substantially homogeneous mixture, removing the solvent, adding a curing agent, and ultrasonicating the mixture.

-

Sheet And Tube Siloxane Polymers Containing A Pendent Organofunctional Group

view source -

US Patent:59772484, Nov 2, 1999

-

Filed:Jun 3, 1998

-

Appl. No.:9/089701

-

Inventors:Chenggang Chen - Cleveland OH

Dimitris Elias Katsoulis - Midland MI

Malcolm Edward Kenney - Cleveland Heights OH -

Assignee:Dow Corning Corporation - Midland MI

Case Western Reserve University - Cleveland OH -

International Classification:C08K 516

-

US Classification:524717

-

Abstract:Gels, cast films, coatings, extruded rods, extruded fibers, compression molded discs, and machined compression molded discs, are made from organopolysiloxane sheet or tube polymers such as an apophyllite-derived 3-cyanopropyldimethyl siloxy sheet polymer of the formula [((NCC. sub. 3 H. sub. 6)(CH. sub. 3). sub. 2 SiO). sub. x (HO). sub. 1-x SiO. sub. 1. 5 ]. sub. n. Polymers are prepared by contacting sheet or tube silicates with an organohalosilane containing at least one polar group such as cyanoalkyl, acyloxy, or haloalkyl, in the presence of a polar solvent or a mixture of a polar solvent and a non-polar solvent; and heating the mixture until a polymer is formed.

-

Silicone Gels And Composites From Sheet And Tube Organofunctional Siloxane Polymers

view source -

US Patent:60137053, Jan 11, 2000

-

Filed:Sep 17, 1998

-

Appl. No.:9/156136

-

Inventors:Chenggang Chen - Cleveland OH

Dimitris Elias Katsoulis - Midland MI

Malcolm Edward Kenney - Cleveland Heights OH -

Assignee:Dow Corning Corporation - Midland MI

-

International Classification:C08K 534

-

US Classification:524100

-

Abstract:Articles of manufacture, such as bulk composites, composite coatings, and composite films, can be prepared by exposing a gel to air, and allowing it to stand at room temperature to cure. The gel is obtained by mixing an organopolysiloxane sheet or tube polymer with an alkoxysilane. Organopolysiloxane sheet or tube polymers are obtained by contacting sheet or tube silicates with an organohalosilane and a solvent, and heating the mixture.

-

Sheet And Tube Siloxane Polymers Containing Multiple Pendent Groups

view source -

US Patent:59772816, Nov 2, 1999

-

Filed:Jun 3, 1998

-

Appl. No.:9/089700

-

Inventors:Chenggang Chen - Cleveland OH

Dimitris Elias Katsoulis - Midland MI

Malcolm Edward Kenney - Cleveland Heights OH -

Assignee:Case Western Reserve University - Cleveland OH

Dow Corning Corporation - Midland MI -

International Classification:C08G 7706

-

US Classification:528 24

-

Abstract:A method for synthesizing an apophyllite-derived 3-cyanopropyldimethylsiloxy-5-hexenyldimethylsiloxy sheet polymer (A-CM. sub. 2 -HEM. sub. 2); an apophyllite-derived 3-cyanopropyldimethylsiloxy-vinyldimethylsiloxy sheet polymer (A-CM. sub. 2 -VM. sub. 2); and an apophyllite-derived 3-cyanopropyldimethylsiloxy-n-decyldimethylsiloxy sheet polymer (A-CM. sub. 2 -DM. sub. 2). These polymers form gels with simple polar solvents such as acetone and therefore can be easily processed. The first two of the polymers, i. e. , A-CM. sub. 2 -HEM. sub. 2 and A-CM. sub. 2 -VM. sub. 2, form gels with polar solvents carrying olefinic linkages, and these gels can be crosslinked into sheet composites having fully exfoliated organosilicon sheets in an organic matrix.

-

Sheet And Tube Organosilicon Polymers

view source -

US Patent:56272413, May 6, 1997

-

Filed:Sep 19, 1996

-

Appl. No.:8/710700

-

Inventors:Chenggang Chen - Cleveland OH

Dimitris E. Katsoulis - Midland MI

Malcolm E. Kenney - Cleveland Heights OH -

Assignee:Dow Corning Corporation - Midland MI

Case Western University - Cleveland OH -

International Classification:C08G 7700

-

US Classification:525474

-

Abstract:A method of making an organopolysiloxane sheet or tube polymer involves contacting a sheet or tube silicate with an organo-H-chlorosilane to form an organosiloxane sheet or tube polymer with pendent. tbd. Si--H groups. Subsequently, the organosiloxane sheet or tube polymer with pendent. tbd. Si--H groups is contacted with an alkenyl group containing compound in the presence of a hydrosilation catalyst. The catalyst is used in an amount effective to catalyze a hydrosilation reaction between the alkenyl group on the alkenyl group containing compound and the hydride functionality on the organosiloxane sheet or tube polymer with pendent. tbd. Si--H groups, to form the organopolysiloxane sheet or tube polymer,.

-

Highly Conductive Strain Resilient Electronics Interconnects And Traces

view source -

US Patent:20220199281, Jun 23, 2022

-

Filed:Mar 15, 2022

-

Appl. No.:17/695144

-

Inventors:- Wright-Patterson AFB OH, US

Ajit K Roy - Beavercreek OH, US

Chenggang Chen - Beavercreek OH, US -

International Classification:H01B 1/04

-

Abstract:An electrically conductive, flexible, strain resilient product is produced by mixing metal coated carbon nanotube networks with a liquid polymeric resin to produce a liquid mixture, and the mixture is cured to produce the product. The networks may include welded junctions between nanotubes formed by depositing and melting metal nanoparticles on the nanotubes to form the metal coating. After the mixing step the liquid mixture may be deposited on a flexible substrate in the form of an electrical circuit. The mixing step may further include mixing the composite with a volatile solvent to produce a selected viscosity. Then, a three-dimensional printer may be used to print the product, such as an electrical circuit, on a substrate. The product is cured in an atmosphere that absorbs the solvent. The conductivity of the mixture may be adjusted by adjusting the weight percentage of the metal coated carbon nanotube networks from 50% to 90%, but a preferred range is between 75% and 85%.

Resumes

Senior Scientist

view sourceLocation:

Dayton, OH

Industry:

Research

Work:

Air Force Research Laboratory

Senior Scientist

Senior Scientist

Education:

Case Western Reserve University 1993 - 1998

Doctorates, Doctor of Philosophy, Philosophy, Chemistry

Doctorates, Doctor of Philosophy, Philosophy, Chemistry

Skills:

Molecular Biology

Simulations

Data Analysis

Spectroscopy

Program Management

Biochemistry

Materials

R&D

Materials Science

Characterization

Nanotechnology

Simulations

Data Analysis

Spectroscopy

Program Management

Biochemistry

Materials

R&D

Materials Science

Characterization

Nanotechnology

Interests:

Science and Technology

Vehicle Records

-

Chenggang Chen

view source -

Address:3760 Mesquite Dr, Beavercreek, OH 45440

-

Phone:(937)4272632

-

VIN:2T1BR32E27C786280

-

Make:TOYOTA

-

Model:COROLLA

-

Year:2007

Youtube

Get Report for Chenggang G Chen from Beavercreek, OH, age ~58