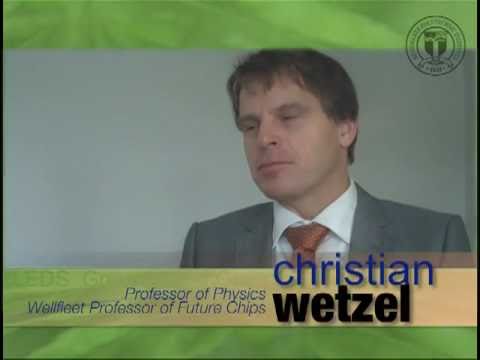

Christian M Wetzel

age ~65

from Oakland, CA

- Also known as:

-

- Christphr M Wetzel

- Christi Wetzel

- Christian Bindereif

Christian Wetzel Phones & Addresses

- Oakland, CA

- 64 23Rd St, Troy, NY 12180

- Tampa, FL

- El Cerrito, CA

Isbn (Books And Publications)

Properties, Processing and Applications of Gallium Nitride and Related Semiconductors

view sourceAuthor

Christian Wetzel

ISBN #

0852969538

Resumes

Program Chair

view sourceLocation:

Albany, NY

Industry:

Semiconductors

Work:

Rensselaer Polytechnic Institute Aug 2015 - Jun 2018

Associate Dean of Science For Research and Graduate Programs

International Conference on Nitride Semiconductors 13 Aug 2015 - Jun 2018

Program Chair

Optical Society of America 2015 - 2017

General Chair - Conference on Laser and Electro Optics Applications and Technology

Lawrence Berkeley National Laboratory Jul 2015 - Jun 2016

Affiliate

Rensselaer Polytechnic Institute 2004 - 2016

Professor

Associate Dean of Science For Research and Graduate Programs

International Conference on Nitride Semiconductors 13 Aug 2015 - Jun 2018

Program Chair

Optical Society of America 2015 - 2017

General Chair - Conference on Laser and Electro Optics Applications and Technology

Lawrence Berkeley National Laboratory Jul 2015 - Jun 2016

Affiliate

Rensselaer Polytechnic Institute 2004 - 2016

Professor

Education:

Technical University of Munich 1981 - 1988

University of California, Berkeley

University of California, Berkeley

Skills:

Thin Films

Characterization

Nanotechnology

Materials Science

Optoelectronics

Physics

Semiconductors

Solid State Physics

Afm

Solid State Lighting

R&D

Microfabrication

Optics

Pvd

Spectroscopy

Cvd

Photolithography

Sputtering

Scanning Electron Microscopy

Design of Experiments

Experimentation

Photovoltaics

Sensors

Mems

Powder X Ray Diffraction

Nanomaterials

Photonics

Device Characterization

Laser

Failure Analysis

Silicon

Solar Cells

Nanofabrication

Xps

Etching

Group Iii Nitride Gan Technology

Semiconductor Epitaxy

Metal Organic Vapor Phase Epitaxy

Green Energy Technology

Labview

Tem

Electronic and Optoelectronic Integration

Color Science

Full Spectrum Light Emitting Diodes

Concentrator Solar Cell Junctions

Materials Characterization

Semiconductor Device Fabrication

Thin Film Integration

Gan on Si Technology

Characterization

Nanotechnology

Materials Science

Optoelectronics

Physics

Semiconductors

Solid State Physics

Afm

Solid State Lighting

R&D

Microfabrication

Optics

Pvd

Spectroscopy

Cvd

Photolithography

Sputtering

Scanning Electron Microscopy

Design of Experiments

Experimentation

Photovoltaics

Sensors

Mems

Powder X Ray Diffraction

Nanomaterials

Photonics

Device Characterization

Laser

Failure Analysis

Silicon

Solar Cells

Nanofabrication

Xps

Etching

Group Iii Nitride Gan Technology

Semiconductor Epitaxy

Metal Organic Vapor Phase Epitaxy

Green Energy Technology

Labview

Tem

Electronic and Optoelectronic Integration

Color Science

Full Spectrum Light Emitting Diodes

Concentrator Solar Cell Junctions

Materials Characterization

Semiconductor Device Fabrication

Thin Film Integration

Gan on Si Technology

Interests:

Science and Technology

Education

Education

Languages:

English

French

Spanish

Japanese

German

French

Spanish

Japanese

German

Christian Wetzel

view sourceUs Patents

-

Method Of Gallium Nitride Growth Over Metallic Substrate Using Vapor Phase Epitaxy

view source -

US Patent:20110117376, May 19, 2011

-

Filed:Nov 16, 2010

-

Appl. No.:12/947409

-

Inventors:Mingwei Zhu - Sunnyvale CA, US

Theeradetch Detchprohm - Niskayuna NY, US

Christian Wetzel - Troy NY, US -

International Classification:C30B 25/18

B32B 15/04 -

US Classification:428457, 117 88

-

Abstract:The current invention introduces a method of crystal film's growth of Gallium Nitride and related alloys over a novel class of the substrates using Vapor Phase Epitaxy technique. This said novel class of the substrates comprises single crystal lattice matched, partially matched or mismatched metallic substrates. The use of such substrates provides exceptional thermal conductivity and application flexibility, since they can be easily removed or patterned by chemical etching for the purposes of additional contact formation, electromagnetic radiation extraction, packaging or other purposes suggested or discovered by the skilled artisan. In particular, if patterned, the remaining portions of the said substrates can be utilized as contacts to the semiconductor layers grown on them. In addition, the said metallic substrates are significantly more cost effective than most of the conventional substrates. The use of Vapor Phase Epitaxy allows growing the epitaxial layers with different and/or variable alloy composition, as well as heterostructures and superlattices.

-

Method Of Group Iii Metal - Nitride Material Growth Using Metal Organic Vapor Phase Epitaxy

view source -

US Patent:20110254134, Oct 20, 2011

-

Filed:Apr 15, 2011

-

Appl. No.:13/087614

-

Inventors:Theeradetch Detchprohm - Niskayuna NY, US

Mingwei Zhu - Santa Clara CA, US

Christian Wetzel - Troy NY, US -

International Classification:H01L 29/20

B32B 38/10

C30B 25/02 -

US Classification:257615, 117104, 156701, 257E29089

-

Abstract:The non-polar or semi-polar Nitride film is grown using Metal Organic Vapor Phase Epitaxy over a substrate. The in-situ grown seed layer comprising Magnesium and Nitrogen is deposited prior to the Nitride film growth. The said seed layer enhances the crystal growth of the Nitride material and makes it suitable for electronics and optoelectronics applications. The use of non-polar and/or semi-polar epitaxial films of the Nitride materials allows avoiding the unwanted effects related to polarization fields and associated interface and surface charges, thus significantly improving the semiconductor device performance and efficiency. In addition, the said seed layer is also easily destroyable by physical or chemical stress, including the ability to dissolve in water or acid, which makes the substrate removal process available and easy. The substrate removal provides the possibility to achieve exceptional thermal conductivity and application flexibility, such as additional contact formation, electromagnetic radiation extraction, packaging or other purposes suggested or discovered by the skilled artisan.

-

Semiconductor Device With Efficient Carrier Recombination

view source -

US Patent:20120032210, Feb 9, 2012

-

Filed:Aug 3, 2011

-

Appl. No.:13/197671

-

Inventors:Alexei Koudymov - Troy NY, US

Christian Martin Wetzel - Troy NY, US -

International Classification:H01L 33/20

-

US Classification:257 94, 257E33048

-

Abstract:The present invention introduces the novel, improved design approach of the semiconductor devices that utilize the effect of carrier recombination, for example, to produce the electromagnetic radiation. The approach is based on the separate control over the injection of the electrons and holes into the active region of the device. As a result, better recombination efficiencies can be achieved, and the effect of the wavelength shift of the produced radiation can be eliminated. The devices according to the present invention outperform existing solid state light and electromagnetic radiation sources and can be used in any applications where solid state light sources are currently involved, as well as any applications future discovered.

-

Method Of Fabricating An Ohmic Contact To N-Type Gallium Nitride

view source -

US Patent:20120052679, Mar 1, 2012

-

Filed:Aug 31, 2011

-

Appl. No.:13/222800

-

Inventors:Wenting Hou - Troy NY, US

Theeradetch Detchprohm - Niskayuna NY, US

Christian Martin Wetzel - Troy NY, US -

International Classification:H01L 21/28

-

US Classification:438660, 257E21158

-

Abstract:A method of providing a metal contact to n-type Gallium Nitride is disclosed. The method does not require high temperatures that often lead to a degradation of semiconductor materials, dielectric films, interfaces and/or metal-semiconductor junctions. The method can be applied at practically any step of a semiconductor device fabrication process and results in high quality ohmic contact with low contact resistance and high current handling capability. Present invention significantly simplifies the fabrication process of semiconductor devices, such as Gallium Nitride-based Light Emitting Diodes and Laser Diodes, while improving the resulting performance of the said devices. The invention can also be applied to improve the performance of electronic devices based on Gallium Nitride material system, especially where an additional annealing step is beneficial during the fabrication process.

-

Free-Standing Mounted Light Emitting Diodes For General Lighting

view source -

US Patent:20110042709, Feb 24, 2011

-

Filed:Aug 17, 2010

-

Appl. No.:12/857760

-

Inventors:Christoph Stark - Troy NY, US

Christian Wetzel - Troy NY, US

Theeradetch Detchprohm - Niskayuna NY, US -

International Classification:H01L 33/62

-

US Classification:257 99, 257E33066

-

Abstract:The current invention introduces a semiconductor light emitting device mounted in a free-standing way for enhanced light extraction and handling simplicity. The free-standing mount is based on the mechanical strength of the current carrying connectors, such as wires or bonds. Such mounted LED die can be placed into standard light bulb body for compatibility with existing household, car, consumer electronics or industrial light sources. The current invention provides increased light extraction efficiency which makes general LED lighting simpler and cheaper. The mounting into a conventional light bulb provides the consumer with the ease of handling and mounting.

-

Growth Of Cubic Crystalline Phase Structure On Silicon Substrates And Devices Comprising The Cubic Crystalline Phase Structure

view source -

US Patent:20200006597, Jan 2, 2020

-

Filed:Sep 11, 2019

-

Appl. No.:16/567535

-

Inventors:- Albuquerque NM, US

Seung-Chang Lee - Albuquerque NM, US

Christian Wetzel - Troy NY, US

Mark Durniak - Troy NY, US -

International Classification:H01L 33/32

H01L 21/02

H01L 21/78

H01L 33/00

H01L 33/04

H01L 33/18

H01L 29/04 -

Abstract:A method of forming a semiconductor structure includes providing a substrate comprising a first material portion and a single crystal silicon layer on the first material portion. The substrate further comprises a major front surface, a major backside surface opposing the major front surface, and a plurality of grooves positioned in the major front surface. A buffer layer is deposited in one or more of the plurality of grooves. A semiconductor material is epitaxially grown over the buffer layer and in the one or more plurality of grooves, the epitaxially grown semiconductor material comprising a hexagonal crystalline phase layer and a cubic crystalline phase structure disposed over the hexagonal crystalline phase.

-

Growth Of Cubic Crystalline Phase Structure On Silicon Substrates And Devices Comprising The Cubic Crystalline Phase Structure

view source -

US Patent:20190103481, Apr 4, 2019

-

Filed:Nov 14, 2018

-

Appl. No.:16/191197

-

Inventors:- Albuquerque NM, US

Seung-Chang Lee - Albuquerque NM, US

Christian Wetzel - Troy NY, US

Mark Durniak - Troy NY, US -

International Classification:H01L 29/778

H01L 29/78

H01L 29/08

H01L 29/06

H01L 21/02

H01S 5/32

H01L 29/04

H01L 29/66

H01L 29/423

H01L 29/205

H01S 5/343

H01L 33/00

H01S 5/02

H01L 33/24

H01L 29/40

H01S 5/227

H01S 5/22

H01L 33/32 -

Abstract:A transistor comprises a substrate comprising a Group III/V compound semiconductor material having a cubic crystalline phase structure positioned on a hexagonal crystalline phase layer having a first region and a second region, the cubic crystalline phase structure being positioned between the first region and the second region of the hexagonal crystalline phase layer. A source region and a drain region are both positioned in the Group III/V compound semiconductor material. A channel region is in the Group III/V compound semiconductor material. A gate is over the channel region. An optional backside contact can also be formed. A source contact and electrode are positioned to provide electrical contact to the source region. A drain contact and electrode are positioned to provide electrical contact to the drain region. Methods of forming transistors are also disclosed.

-

Growth Of Cubic Crystalline Phase Structure On Silicon Substrates And Devices Comprising The Cubic Crystalline Phase Structure

view source -

US Patent:20170194476, Jul 6, 2017

-

Filed:Mar 22, 2017

-

Appl. No.:15/466461

-

Inventors:- Albuquerque NM, US

Seung-Chang Lee - Albuquerque NM, US

Christian Wetzel - Troy NY, US

Mark Durniak - Troy NY, US -

International Classification:H01L 29/778

H01L 21/02

H01L 29/08

H01L 29/66

H01L 29/205

H01L 29/04

H01L 21/306 -

Abstract:A transistor comprises a substrate comprising a Group III/V compound semiconductor material having a cubic crystalline phase structure positioned on a hexagonal crystalline phase layer having a first region and a second region, the cubic crystalline phase structure being positioned between the first region and the second region of the hexagonal crystalline phase layer. A source region and a drain region are both positioned in the Group III/V compound semiconductor material. A channel region is in the Group III/V compound semiconductor material. A gate is over the channel region. An optional backside contact can also be formed. A source contact and electrode are positioned to provide electrical contact to the source region. A drain contact and electrode are positioned to provide electrical contact to the drain region. Methods of forming transistors are also disclosed.

Googleplus

Christian Wetzel

Tagline:

Less stuff, more happiness

Christian Wetzel

Tagline:

Leben & lassen

Christian Wetzel

Christian Wetzel

Christian Wetzel

Relationship:

Married

Christian Wetzel

Christian Wetzel

Christian Wetzel

Flickr

Myspace

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view source

Christian Wetzel

view sourceYoutube

Get Report for Christian M Wetzel from Oakland, CA, age ~65