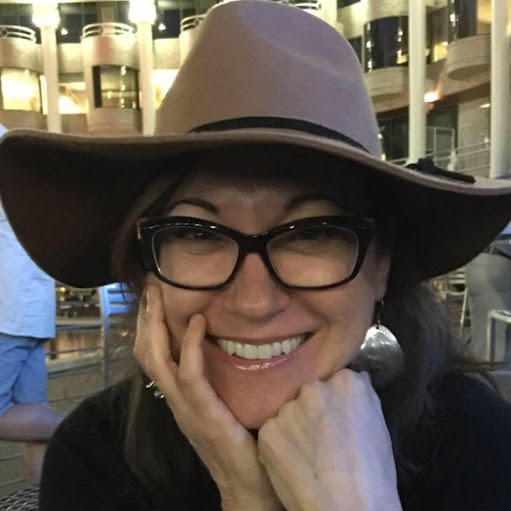

Dale A Lehman

age ~63

from Westlake, OH

- Also known as:

-

- Dale N

- Phone and address:

-

3627 W 139Th St, Cleveland, OH 44111

(216)2523523

Dale Lehman Phones & Addresses

- 3627 W 139Th St, Cleveland, OH 44111 • (216)2523523

- Westlake, OH

- Carmel, IN

- Noblesville, IN

Isbn (Books And Publications)

The Telecommunications Act of 1996: The "Costs" of Managed Competition

view sourceAuthor

Dale E. Lehman

ISBN #

0792379578

Name / Title

Company / Classification

Phones & Addresses

President

Corrosion Proof Equipment Corp

Manufactures Air Purification Equipment

Manufactures Air Purification Equipment

4145 E 79 St, Cleveland, OH 44105

(216)2715566

(216)2715566

Principal

J and L Glass Company

Ret Paint/Glass/Wallpaper

Ret Paint/Glass/Wallpaper

22395 N Millcreek Rd, Cicero, IN 46034

BARBERTON CHURCH OF GOD

Barberton, OH

GRAPHITE EQUIPMENT MANUFACTURING CO

Bedford, OH

Us Patents

-

Molten Metal Pump

view source -

US Patent:6457940, Oct 1, 2002

-

Filed:Jul 21, 2000

-

Appl. No.:09/621201

-

Inventors:Dale T. Lehman - Solon OH 44139

-

International Classification:F04D 706

-

US Classification:415206, 298894, 4151212, 416235

-

Abstract:An impeller for a molten metal pump includes an exterior bearing mounting surface that is trued about the axis of the impeller and drive shaft assembly. Another impeller arrangement includes a pumping chamber having an axis offset from the impeller axis to achieve a volute pumping arrangement. In a further arrangement, the impeller is provided with peripheral pumping chambers intersecting the peripheral surface of the impeller. In each of the foregoing arrangements, a plate may be fixed to the pump drive shaft at a location axially spaced from the impeller inlet to screen debris and to pump molten metal to the impeller inlet.

-

Molten Metal Pump Impeller

view source -

US Patent:6468039, Oct 22, 2002

-

Filed:May 25, 2001

-

Appl. No.:09/865772

-

Inventors:Dale T. Lehman - Solon OH 44139

-

International Classification:F04D 2938

-

US Classification:416181, 416185, 415200

-

Abstract:An impeller for a molten metal pump includes a base and a plurality of vanes having openings for flow of molten metal there through during pumping, Alternatively, or in combination with the vane openings, a single drain opening extending through the base of the impeller may be provided remote of the rotational axis of the impeller. In another embodiment, an impeller provides axial and radial pumping. The multiflow impeller includes at least one pumping chamber inclined into the direction of rotation to provide axial pumping.

-

Post Mounting System And Method For Molten Metal Pump

view source -

US Patent:6562286, May 13, 2003

-

Filed:Mar 13, 2001

-

Appl. No.:09/804845

-

Inventors:Dale T. Lehman - Solon OH 44139

-

International Classification:C21B 712

-

US Classification:266 45, 266239, 4174233

-

Abstract:A molten metal pump includes a base member submerged in the molten metal, a support member supported above the level of the molten metal by a post extending from the base member through a clearance bore in the support member and a coupling securing the post to the support member. The coupling is mounted to the support surface and includes gripping members operable to a locked position engaging the upper end of the post and to an unlocked position releasing the post. The coupling is aligned with the clearance bore in the support member to permit the post to be assembled or disassembled by axial movement through the clearance bore when the coupling is in the unlocked position.

-

Molten Metal Pump Impeller

view source -

US Patent:6755614, Jun 29, 2004

-

Filed:Oct 16, 2002

-

Appl. No.:10/272221

-

Inventors:Dale T. Lehman - Solon OH 44139

-

International Classification:F04D 706

-

US Classification:415200, 416185, 416241 B

-

Abstract:An impeller for a molten metal pump includes a base and a plurality of vanes having openings for flow of molten metal there through during pumping. Alternatively, or in combination with the vane openings, a single drain opening extending through the base of the impeller may be provided remote of the rotational axis of the impeller. In another embodiment, an impeller provides axial and radial pumping. The multiflow impeller includes at least one pumping chamber inclined into the direction of rotation to provide axial pumping.

-

Molten Metal Pump Impeller

view source -

US Patent:6837678, Jan 4, 2005

-

Filed:Sep 25, 2003

-

Appl. No.:10/670537

-

Inventors:Dale T. Lehman - Solon OH, US

-

International Classification:F04D 2938

-

US Classification:415181, 415200, 415185

-

Abstract:An impeller for a molten metal pump includes a base and a plurality of vanes having openings for flow of molten metal there through during pumping. Alternatively, or in combination with the vane openings, a single drain opening extending through the base of the impeller may be provided remote of the rotational axis of the impeller. In another embodiment, an impeller provides axial and radial pumping. The multiflow impeller includes at least one pumping chamber inclined into the direction of rotation to provide axial pumping.

-

Heat Exchanger

view source -

US Patent:41191412, Oct 10, 1978

-

Filed:May 12, 1977

-

Appl. No.:5/796175

-

Inventors:Bruno H. Thut - Bainbridge OH

Dale T. Lehman - Solon OH -

International Classification:F28F 902

F28F 2102 -

US Classification:165 82

-

Abstract:A heat exchanger comprising an elongated tubular cylindrical member having fluid ingress and egress openings adjacent to its opposite ends and external flanges at opposite ends one of which flanges has a counterbore facing in the direction away from the cylindrical member. A plurality of graphite tubes within the cylindrical member having their opposite ends connected to graphite headers one of which is connected through a graphite end member to one end of the cylindrical member and the other of which has an outside diameter slightly less than the inside diameter of the cylindrical member and within which it is slidable or floats. The floating header has an external circumferential groove with outwardly inclined ends. A seal is provided at the end of the cylindrical member at which the floating header is located which seal includes packing in the counterbore in the adjacent flange and a gland member slidable on the floating header and adjustable towards the flange. A part of the gland member overlies one end of the external groove in the floating header member.

-

Heat Exchanger

view source -

US Patent:42444233, Jan 13, 1981

-

Filed:Jul 17, 1978

-

Appl. No.:5/924912

-

Inventors:Bruno H. Thut - Bainbridge OH

Dale T. Lehman - Solon OH -

International Classification:F28F 912

-

US Classification:165 82

-

Abstract:A heat exchanger comprising an elongated tubular cylindrical member having fluid ingress and egress openings adjacent to its opposite ends and external flanges at opposite ends one of which flanges has a counterbore facing in the direction away from the cylindrical member. A plurality of graphite tubes within the cylindrical member having their opposite ends connected to graphite headers one of which is connected through a graphite end member to one end of the cylindrical member and the other of which has an outside diameter slightly less than the inside diameter of the cylindrical member and within which it is slidable or floats. The floating header has an external circumferential groove with outwardly inclined ends. A seal is provided at the end of the cylindrical member at which the floating header is located which seal includes packing in the counterbore in the adjacent flange and a gland member slidable on the floating header and adjustable towards the flange. A part of the gland member overlies one end of the external groove in the floating header member.

Resumes

Dale Lehman

view source

Dale Lehman

view source

Dale Lehman

view source

Dale Lehman

view sourceLocation:

United States

Classmates

Dale Lehman

view sourceSchools:

Acalanes High School Lafayette CA 1971-1975

Community:

Karen Gibbons, Eleanor Ellie

Dale Lehman

view sourceSchools:

Fairview Elementary School Olathe CO 1951-1959

Community:

Lois Mount, Robert King

Dale Lehman

view sourceSchools:

St. Joseph School Harvard IL 1966-1975

Community:

Bryan Davidson, Cheryl Anderson, Al Santeler

Dale Lehman

view sourceSchools:

Bishop McCort High School Johnstown PA 1982-1986

Community:

Robert Heffley, Daniel Fitzpatrick

Dale Lehman, Truman High ...

view source

St. Joseph School, Harvar...

view sourceGraduates:

Bryan Henning (1990-2001),

Danielle Thomas (1990-1993),

Michael Drymiller (1957-1965),

Dale Lehman (1966-1975),

Angela Reising (1983-1986)

Danielle Thomas (1990-1993),

Michael Drymiller (1957-1965),

Dale Lehman (1966-1975),

Angela Reising (1983-1986)

Plaxo

Dale Lehman

view sourceBaltimoreSenior Web Developer at NMR Consulting

Myspace

Youtube

Flickr

Dale Lehman

view source

Dale Lehman

view source

Dale Lehman

view source

Dale Lehman

view source

Dale Lehman

view source

Mike Dale Lehman

view source

Dale Lehman

view source

Dale Lehman

view sourceGoogleplus

Dale Lehman

Work:

Graphite Equipment Mfg

Education:

Ohio University

Dale Lehman

Dale Lehman

Dale Lehman

Dale Lehman

Dale Lehman

Dale Lehman

Get Report for Dale A Lehman from Westlake, OH, age ~63