David F Lahrman

age ~66

from Powell, OH

- Also known as:

-

- David Frank Lahrman

- David Kathryn Lahrman

- David A Lahrman

- Dave F Lahrman

- Phone and address:

-

327 Weatherburn Dr, Powell, OH 43065

(614)4315436

David Lahrman Phones & Addresses

- 327 Weatherburn Dr, Powell, OH 43065 • (614)4315436

- Columbus, OH

- Mason, OH

- Cincinnati, OH

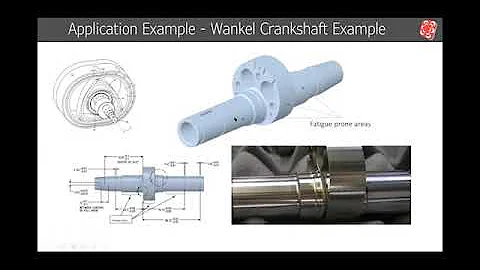

Us Patents

-

Shock Pressure Gauge For Laser Peening Apparatus

view source -

US Patent:6412331, Jul 2, 2002

-

Filed:Nov 19, 1999

-

Appl. No.:09/443811

-

Inventors:Allan H. Clauer - Worthington OH

Craig T. Walters - Powell OH

David F. Lahrman - Powell OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:G01L 500

-

US Classification:73 1102

-

Abstract:An apparatus for measuring the strength of a pressure pulse created from a laser peening device. The apparatus is reusable, and includes a pressure-sensitive medium, a back-up disk, and a cap, all disposed within a housing having a removable lid. All components of the apparatus are replaceable, thereby allowing an operator to utilize the apparatus more than once despite the harsh environment of laser peening.

-

Utilizing Altered Vibration Responses Of Workpieces, Such As Gas Turbine Engine Blades

view source -

US Patent:6462308, Oct 8, 2002

-

Filed:Nov 23, 1999

-

Appl. No.:09/448683

-

Inventors:David F. Lahrman - Powell OH

Allan H. Clauer - Worthington OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:B23K 2600

-

US Classification:21912185, 21912183

-

Abstract:An apparatus and method of utilizing natural frequency shifts of a laser shock processed workpiece to determine if sufficient laser shock processing has been accomplished.

-

Mechanical Gauges For Quality Assurance Of Laser Peening

view source -

US Patent:6483578, Nov 19, 2002

-

Filed:Jun 12, 2000

-

Appl. No.:09/592534

-

Inventors:Allan H. Clauer - Worthington OH

Steven M. Toller - Dublin OH

Jeff L. Dulaney - Dublin OH

David F. Lahrman - Powell OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:G01J 100

-

US Classification:356213, 148508

-

Abstract:A method and apparatus for measuring the quality of a laser peening process, which includes a test element, a mount for the test element, wherein the test element is mounted at a preselected point in the anticipated path of a laser pulse, the laser pulse irradiates the test element, the deflection of the test element is measured in the direction substantially perpendicular and away from the impacted surface of the test element, and the deflection measurement is compared to a previously generated chart showing the relationship between characteristics of test elements and desired material properties.

-

Shock Pressure Gauge For Laser Peening Apparatus

view source -

US Patent:6539773, Apr 1, 2003

-

Filed:Jun 18, 2001

-

Appl. No.:09/883712

-

Inventors:Allan H. Clauer - Worthington OH

Craig T. Walters - Powell OH

David F. Lahrman - Powell OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:G01L 500

-

US Classification:73 1102, 73 1209

-

Abstract:An apparatus for measuring the strength of a pressure pulse created from a laser peening device. The apparatus is reusable, and includes a pressure-sensitive medium, a back-up disk, and a cap, all disposed within a housing having a removable lid. All components of the apparatus are replaceable, thereby allowing an operator to utilize the apparatus more than once despite the harsh environment of laser peening.

-

Overlay Control For Laser Peening

view source -

US Patent:6548782, Apr 15, 2003

-

Filed:Jan 23, 2001

-

Appl. No.:09/767528

-

Inventors:Steven E. Dykes - Powell OH

Allan H. Clauer - Worthington OH

Jeff L. Dulaney - Dublin OH

David F. Lahrman - Powell OH

Mark OLoughlin - Galloway OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:B23K 2600

-

US Classification:21912185

-

Abstract:A method of controlling the application of laser peening overlays on the surface of a workpiece to reduce the variability of shock waves generated therein, comprises applying an energy-absorbing overlay to a portion of the surface of a workpiece, measuring the thickness of the energy-absorbing overlay in at least one location on the energy-absorbing overlay, applying a transparent overlay material over the energy-absorbing overlay, measuring the thickness of the transparent overlay in at least one location on the transparent overlay, determining if the measured values for each overlay is within a specified range, and directing a pulse of coherent energy to the workpiece to create a shock wave therein when the measured values are within the specified range.

-

Method Using Laser Shock Processing To Provide Improved Residual Stress Profile Characteristics

view source -

US Patent:6664506, Dec 16, 2003

-

Filed:Jul 29, 2002

-

Appl. No.:10/207560

-

Inventors:Allan H. Clauer - Worthington OH

David F. Lahrman - Powell OH

Jeff L. Dulaney - Dublin OH

Steve M. Toller - Dublin OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:B23K 2600

-

US Classification:21912185

-

Abstract:Various laser shock processing methods are provided to establish selective compressive residual stress distribution profiles within a workpiece. An asymmetrical stress distribution profile may be formed through the thickness of a thin section of a gas turbine engine airfoil. One method involves simultaneously irradiating a workpiece with a set of laser beams to form a corresponding set of adjacent non-overlapping laser shock peened surfaces, enabling the shockwaves to encounter one another. Additionally, opposite sides of the workpiece may be irradiated at different times to form opposing laser shock peened surfaces, enabling the shockwaves to meet at a location apart from the midplane. Furthermore, opposite sides of the workpiece may be irradiated simultaneously using laser beams having different pulse lengths to form opposing laser shock peened surfaces. Moreover, opposite sides of the workpiece may be irradiated simultaneously to form a set of laterally offset laser shock peened surfaces.

-

Articles Having Improved Residual Stress Profile Characteristics Produced By Laser Shock Peening

view source -

US Patent:6752593, Jun 22, 2004

-

Filed:Jul 29, 2002

-

Appl. No.:10/207622

-

Inventors:Allan H. Clauer - Worthington OH

David F. Lahrman - Powell OH

Jeff L. Dulaney - Dublin OH

Steve M. Toller - Dublin OH -

Assignee:LSP Technologies, Inc. - Dublin OH

-

International Classification:F01D 514

-

US Classification:415200, 416241 R, 21912185, 21912176

-

Abstract:Articles produced by laser shock processing exhibit various compressive residual stress distribution profiles. A gas turbine engine airfoil includes an asymmetrical stress profile formed through the thickness of its thin section. The articles include plural laser shock peened surfaces and plural regions having deep compressive residual stresses imparted by laser shock peening extending into the article from the laser peened surfaces. One article includes at least one set of simultaneously formed, adjacent non-overlapping laser shock peened surfaces. Another article includes at least one set of opposing laser shock peened surfaces formed at different times at opposite sides of the article. Another article includes at least one set of opposing laser shock peened surfaces formed simultaneously at opposite sides of the article using laser beams having different pulse lengths. Another article includes at least one set of laterally offset laser shock peened surfaces simultaneously formed at opposite sides of the article.

-

System For Laser Shock Processing Objects To Produce Enhanced Stress Distribution Profiles

view source -

US Patent:6759626, Jul 6, 2004

-

Filed:Jul 29, 2002

-

Appl. No.:10/207527

-

Inventors:Allan H. Clauer - Worthington OH

David F. Lahrman - Powell OH

Jeff L. Dulaney - Dublin OH

Steve M. Toller - Dublin OH -

Assignee:LP Technologies, Inc. - Dublin OH

-

International Classification:B23K 2600

-

US Classification:2191216, 21912181, 21912182

-

Abstract:Various laser shock processing systems are provided to establish selective compressive residual stress distribution profiles within a workpiece. An asymmetrical stress profile may be formed through the thickness of a thin section of a gas turbine engine airfoil. One system is configured to simultaneously irradiate a workpiece with a set of laser beams to form a corresponding set of adjacent non-overlapping laser shock peened surfaces, enabling the shockwaves to encounter one another. Another system irradiates opposite sides of the workpiece at different times to form opposing laser shock peened surfaces, enabling the shockwaves to meet at a location apart from the mid-plane. Another system simultaneously irradiates opposite sides of the workpiece using laser beams having different pulse lengths to form opposing laser shock peened surfaces. Another system simultaneously irradiates opposite sides of the workpiece to form a set of laterally offset laser shock peened surfaces.

Resumes

Vice President Business Development At Lsp Technologies, Inc.

view sourcePosition:

Vice President Business Development at LSP Technologies, Inc.

Location:

Columbus, Ohio Area

Industry:

Airlines/Aviation

Work:

LSP Technologies, Inc. - Dublin, OH since Mar 2012

Vice President Business Development

LSP Technologies, Inc. - Dublin, OH Jan 2006 - Feb 2012

Director of Business Development

LSP Technologies - Dublin, OH Jan 2001 - Dec 2005

Development Manager

LSP Technologies, Inc. May 1999 - Dec 2000

Principal Engineer

Battelle - Columbus, OH Aug 1993 - May 1999

Research Scientist

Vice President Business Development

LSP Technologies, Inc. - Dublin, OH Jan 2006 - Feb 2012

Director of Business Development

LSP Technologies - Dublin, OH Jan 2001 - Dec 2005

Development Manager

LSP Technologies, Inc. May 1999 - Dec 2000

Principal Engineer

Battelle - Columbus, OH Aug 1993 - May 1999

Research Scientist

Education:

University of Illinois at Urbana-Champaign 1984 - 1986

MS, Metallurgical Engineering University of Cincinnati 1977 - 1982

BS, Material Science and Engineering

MS, Metallurgical Engineering University of Cincinnati 1977 - 1982

BS, Material Science and Engineering

Interests:

Leadership Development, Aviation History, Aviation Photography,

Honor & Awards:

2003 Defense Manufacturing Technology Achievement Award

Nominated for the 1984 R.B. Ingraham Young Engineers Award

David Lahrman

view sourceYoutube

David Lahrman

view sourceFriends:

Greg Jaent, Ken Lahrman, Mark Estremera, Brian Murphy, Mitch Claunch, Pete Umbel

Get Report for David F Lahrman from Powell, OH, age ~66