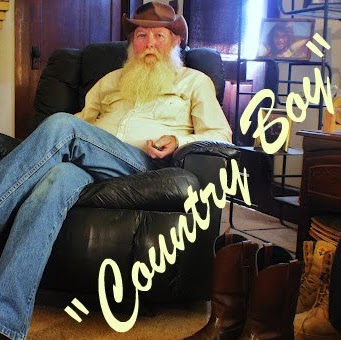

David S Reece

age ~70

from Calhoun, GA

- Also known as:

-

- Dave S Reece

- Phone and address:

- 135 Kelsey Cv SE, Calhoun, GA 30701

David Reece Phones & Addresses

- 135 Kelsey Cv SE, Calhoun, GA 30701

- Fairmount, GA

- Kingsport, TN

- 10 Trellis Ct, Carrollton, GA 30116

- Rome, GA

- Columbus, GA

Us Patents

-

Electrical Cable Having A Self-Sealing Agent And Method For Preventing Water From Contacting The Conductor

view source -

US Patent:6359231, Mar 19, 2002

-

Filed:Jan 8, 2001

-

Appl. No.:09/756533

-

Inventors:David Reece - Carrollton GA

Jonathan Waller - Carrollton GA

Nick Ware - Villa Rica GA

Philip Sasse - Douglasville GA -

Assignee:Southwire Company, a Delaware Corporation - Carrollton GA

-

International Classification:H01B 700

-

US Classification:174110R, 174113 R

-

Abstract:An electrical cable with a stranded central conductor encircled by insulation including a material which provides self-sealing properties to the cable present at least between the adjacent edges of the stranded conductor and the insulation. Preferably, the material is a polymeric material which is flowable at a temperature at least as low as 25Â C. and has a 100 gram needle penetration value greater than 100 tenths of a millimeter at 25Â C.

-

Superconducting Cable

view source -

US Patent:6596945, Jul 22, 2003

-

Filed:Sep 9, 1999

-

Appl. No.:09/392278

-

Inventors:Raburn L. Hughey - Franklin GA

Uday K. Sinha - Carrollton GA

David S. Reece - Carrollton GA

Albert C. Muller - Eidson TN -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B 1200

-

US Classification:1741251, 505886, 505887

-

Abstract:In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0. 2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

-

Superconducting Cable Having A Flexible Former

view source -

US Patent:6864430, Mar 8, 2005

-

Filed:Jan 30, 2002

-

Appl. No.:10/060693

-

Inventors:Raburn L. Hughey - Franklin GA, US

Uday K. Sinha - Carrollton GA, US

David S. Reece - Carrollton GA, US

Albert C. Muller - Eidson TN, US -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B012/00

-

US Classification:1741251, 505230

-

Abstract:In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0. 2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

-

Superconducting Cable Having A Flexible Former

view source -

US Patent:6867375, Mar 15, 2005

-

Filed:Aug 22, 2002

-

Appl. No.:10/226177

-

Inventors:Raburn L. Hughey - Franklin GA, US

Uday K. Sinha - Carrollton GA, US

David S. Reece - Carrollton GA, US

Albert C. Muller - Eidson TN, US -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B012/00

-

US Classification:1741251, 29599, 505231

-

Abstract:In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0. 2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

-

Superconducting Cable Having A Flexible Former

view source -

US Patent:6936772, Aug 30, 2005

-

Filed:Aug 18, 2004

-

Appl. No.:10/920757

-

Inventors:Raburn L. Hughey - Franklin GA, US

Uday K. Sinha - Carrollton GA, US

David S. Reece - Carrollton GA, US

Albert C. Muller - Eidson TN, US -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B012/00

-

US Classification:1741251, 29599, 505231

-

Abstract:In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0. 2%. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

-

Superconducting Cable

view source -

US Patent:6972376, Dec 6, 2005

-

Filed:Dec 15, 2004

-

Appl. No.:11/012623

-

Inventors:Raburn L. Hughey - Franklin GA, US

Uday K. Sinha - Carrollton GA, US

David S. Reece - Carrollton GA, US

Albert C. Muller - Eidson TN, US -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B012/00

-

US Classification:1741251, 29599, 505231

-

Abstract:In order to provide a flexible oxide superconducting cable which is reduced in AC loss, tape-shaped superconducting wires covered with a stabilizing metal are wound on a flexible former. The superconducting wires are preferably laid on the former at a bending strain of not more than 0. 2 %. In laying on the former, a number of tape-shaped superconducting wires are laid on a core member in a side-by-side manner, to form a first layer. A prescribed number of tape-shaped superconducting wires are laid on top of the first layer in a side-by-side manner, to form a second layer. The former may be made of a metal, plastic, reinforced plastic, polymer, or a composite and provides flexibility to the superconducting wires and the cable formed therewith.

-

Electrical Cable Having A Surface With Reduced Coefficient Of Friction

view source -

US Patent:7411129, Aug 12, 2008

-

Filed:Sep 28, 2004

-

Appl. No.:10/952294

-

Inventors:Randy D. Kummer - Villa Rica GA, US

David Reece - Carrollton GA, US

Mark D. Dixon - Carrollton GA, US

John R. Carlson - Newnan GA, US

Hai Lam - Douglasville GA, US

Philip Sasse - Douglasville GA, US -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B 7/00

-

US Classification:174110R, 174120 R, 427118

-

Abstract:The present invention includes a cable having reduced surface friction and the method of manufacture thereof having steps in which a conductor wire is coated with a mixture of a plastic material and lubricating material and in which the coated conductor wire is cooled. The cable includes at least one conductor core and at least one coating of plastic material and incorporates a lubricating material in and/or on the plastic material. The equipment for the manufacturing of electrical cable includes a reel for supplying a conductor wire to an extruding head, which is connected to tanks containing plastic material and lubricating material for coating the conducting wire, and a reel for taking up the cable.

-

Method Of Manufacturing Electrical Cable Having Reduced Required Force For Installation

view source -

US Patent:7557301, Jul 7, 2009

-

Filed:Jan 21, 2008

-

Appl. No.:12/017222

-

Inventors:Randy D. Kummer - Villa Rica GA, US

David Reece - Carrollton GA, US

Mark D. Dixon - Carrollton GA, US

John R. Carlson - Newnan GA, US

Hai Lam - Douglasville GA, US

Philip Sasse - Douglasville GA, US -

Assignee:Southwire Company - Carrollton GA

-

International Classification:H01B 7/00

-

US Classification:174110R, 174120 R, 427118

-

Abstract:Disclosed is a method of manufacturing a finished cable by a process directed to reduce the amount of force required to install the cable. The process involves the extrusion of the cable's outer sheath and the incorporation of a pulling lubricant in connection with, and prior to the completion of, the extrusion to reduce the sheath's surface coefficient of friction as well as reduce the required force to pull the cable for installation. The conductor core is coated with an extruded plastic material with which an appropriate (in amount and type) pulling lubricant is initially combined with the plastic material prior to the formation of the sheath and in which the sheathed conductor core is thereafter cooled, the lubricant either migrating to and/or permeating the sheath to be available at the surface of the sheath at the time of the cable's installation. The preselected lubricant is disclosed as either combined with the plastic material during initial pelletization, or mixed with the plastic pellets prior to introduction of the mixture into the extruding head, or introduced into the extruding head at a separate location downstream from where the plastic material is introduced into the extruding head.

Name / Title

Company / Classification

Phones & Addresses

Principal

Vector/Cutco

Direct Retail Sales

Direct Retail Sales

3659 Regent Dr NW, Kennesaw, GA 30144

Assistant

Calhoun City Board of Education

Elementary/Secondary School

Elementary/Secondary School

399 S Riv St, Calhoun, GA 30701

(706)6293340

(706)6293340

PFEIFFER STATION GENERAL STORE LTD

Manager

Kentucky Fried Chicken of Louisville, Inc

Fast-Food Rest Chain

Fast-Food Rest Chain

1970 Cobb Pkwy NW, Kennesaw, GA 30152

(770)4229716

(770)4229716

CURREK, INC

Owner, Principal

B. Reece

Real Estate Agent/Manager

Real Estate Agent/Manager

26 Rackley Rd, Ellijay, GA 30536

Senior Vice Presiden

Gables Gp, Inc

Isbn (Books And Publications)

Special Trust and Confidence: Envoy Essays in Canadian Diplomacy

view sourceAuthor

David Reece

ISBN #

0886292921

Medicine Doctors

David Scott Reece

view sourceSpecialties:

Internal Medicine

Resumes

Engineering Technician At Ground/Water Treatment And Technology

view sourcePosition:

Engineering Technician at Ground/Water Treatment and Technology

Location:

Wesley Chapel, Florida

Industry:

Industrial Automation

Work:

Ground/Water Treatment and Technology - Tampa. Fl since Jan 2012

Engineering Technician

Technology Transfer Services Mar 2008 - Sep 2011

Technical Content Developer

Eastman Kodak Jan 1982 - Dec 2007

Engineering Technician I&C

Engineering Technician

Technology Transfer Services Mar 2008 - Sep 2011

Technical Content Developer

Eastman Kodak Jan 1982 - Dec 2007

Engineering Technician I&C

Education:

Niagara Falls H.S. 1970 - 1973

Diploma, Mathematics, Mechanical Drawing

Diploma, Mathematics, Mechanical Drawing

Skills:

Troubleshooting

Engineering

Automation

Maintenance & Repair

Engineering

Automation

Maintenance & Repair

David Reece

view sourceLocation:

United States

David Reece

view sourceLocation:

United States

David Reece

view sourceLocation:

United States

David Reece Gray, TN

view sourceWork:

Leclerc Foods USA

Dec 2009 to 2000

Line supervisor currek inc

Medina, OH

Sep 2006 to Aug 2009

Carpenter Flowserve

Kingsport, TN

Mar 2003 to Aug 2006

Precision Mechanic

Dec 2009 to 2000

Line supervisor currek inc

Medina, OH

Sep 2006 to Aug 2009

Carpenter Flowserve

Kingsport, TN

Mar 2003 to Aug 2006

Precision Mechanic

Education:

Medina Senior High medina OH United States

Medina, OH

May 2002

High School Diploma in Student council Medina county career center medina OH United States

Medina, OH

May 2002

High School Diploma

Medina, OH

May 2002

High School Diploma in Student council Medina county career center medina OH United States

Medina, OH

May 2002

High School Diploma

David Reece Atlanta, GA

view sourceWork:

Roger Reece Seminars

Mar 2011 to 2000

Emissions Inspector Roger Reece Seminars

Jan 2011 to 2000

Office Assistant Fat Matts Ribshack

Atlanta, GA

Jun 2010 to Mar 2011

Line Cook/Server Publix Supermarkets Inc

Alpharetta, GA

Apr 2006 to Jun 2010

Assistant Deli Manager Publix Supermarkets Inc

Duluth, GA

Mar 1995 to Apr 2006

Publix Deli RDT Chef

Mar 2011 to 2000

Emissions Inspector Roger Reece Seminars

Jan 2011 to 2000

Office Assistant Fat Matts Ribshack

Atlanta, GA

Jun 2010 to Mar 2011

Line Cook/Server Publix Supermarkets Inc

Alpharetta, GA

Apr 2006 to Jun 2010

Assistant Deli Manager Publix Supermarkets Inc

Duluth, GA

Mar 1995 to Apr 2006

Publix Deli RDT Chef

David Reece

view source

David Reece

view source

David Reece

view source

David Reece

view source

David Reece Williams

view source

David Reece Huneycutt

view source

Dawn David Reece

view source

David J Reece

view sourcePlaxo

David Reece

view sourceDoral, FloridaOver 20 years in Technology working with AT&T, Nuvox, Lucent Technology and Online Service. Strong ability to network in the community. Active in several... Over 20 years in Technology working with AT&T, Nuvox, Lucent Technology and Online Service. Strong ability to network in the community. Active in several community organizations, strong ability to raise money for non-profits. Now working with Broward OIC to help ex-offenders find work

Very active...

David Reece

view sourcePast: Senior Manager, Worldwide Manufacturing at Herbalife International

David Reece

view sourceLeighton Buzzard, Bedfordshire, UK

Classmates

David A. Reece III (Reece)

view sourceSchools:

Ouray High School Ouray CO 1997-2001

Community:

Patricia Richardson, Linda Tomlinson, Lorraine Schmidt, David Woolston, Anna Vicalvi

David Reece

view sourceSchools:

Frontier Academy Greeley CO 2001-2005

David Reece

view sourceSchools:

Ouray High School Ouray CO 1997-2001

Community:

Patricia Richardson, Linda Tomlinson, Lorraine Schmidt, David Woolston, Anna Vicalvi

David Reece

view sourceSchools:

Claiborne County High School Tazewell TN 1993-1997

Community:

Darlene Collins, Roger Earls, Lisa Cupp

David Reece

view sourceSchools:

Red Boiling Springs High School Red Boiling Springs TN 1975-1979

Community:

Michael Mccaleb, Nick Kirby, Robin Jackson

David Reece

view sourceSchools:

Frontier Academy Greeley CO 2001-2005

David Duff (Reece)

view sourceSchools:

Dublin High School Dublin VA 1970-1970

David Reece Reece

view sourceSchools:

El Centro School South Pasadena CA 1978-1982

Community:

Bruce Windoffer, Allison Stanley

Flickr

Googleplus

David Reece

Work:

Titanium Fire

Education:

Saint Paul's college, Dublin

Relationship:

In_a_relationship

About:

Dave, IblameDave, Exus Dominus whatever you know me by. Gamer, Geek, Metal Head and probably other stuff too.

David Reece

Education:

University of the West of England - Bsc Computing

David Reece

Work:

Reece Cinematography LLC - Director/DP

David Reece

David Reece

Relationship:

Single

David Reece

David Reece

David Reece

Youtube

Myspace

Get Report for David S Reece from Calhoun, GA, age ~70