Donald E Zipperian

age ~89

from Tucson, AZ

- Also known as:

-

- Donald Edwin Zipperian

- Donald C Zipperian

- Donal E Zipperian

- Doanld E Zipperian

- Don C Zipperian

- Donald N

Donald Zipperian Phones & Addresses

- Tucson, AZ

- 5380 E Placita Casa Rio, Tucson, AZ 85718 • (602)2990510

Work

-

Position:Administrative Support Occupations, Including Clerical Occupations

Education

-

Degree:Bachelor's degree or higher

Emails

Resumes

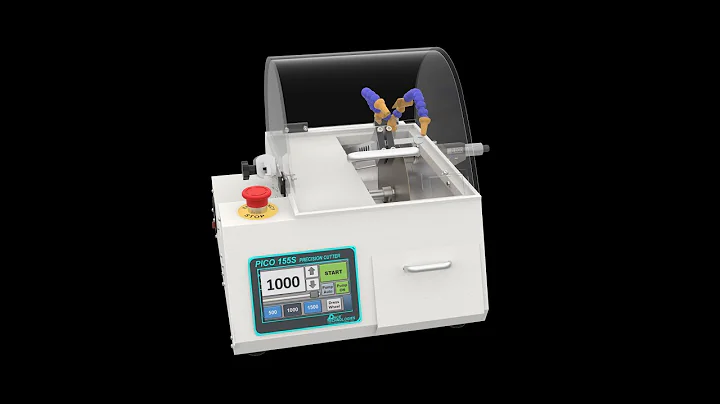

Vice President At Pace Technologies Corp

view sourcePosition:

Vice President and Chief Technical Officer at PACE Technologies, Vice President at PACE Technologies Corp

Location:

Tucson, Arizona Area

Industry:

Research

Work:

PACE Technologies - Tucson, Arizona since Sep 1997

Vice President and Chief Technical Officer

PACE Technologies Corp - Tucson, AZ since Jul 1997

Vice President

Veeco 2002 - 2005

Director of Data Storage

Seagate Technology 1997 - 1999

Manager Advanced Lapping

Buehler 1987 - 1997

General Manager

Vice President and Chief Technical Officer

PACE Technologies Corp - Tucson, AZ since Jul 1997

Vice President

Veeco 2002 - 2005

Director of Data Storage

Seagate Technology 1997 - 1999

Manager Advanced Lapping

Buehler 1987 - 1997

General Manager

Education:

Lake Forrest Graduate College 1992 - 1995

Master of Business Administration (MBA), Business Administration and Management, General University of Arizona 1984 - 1987

Doctor of Philosophy (Ph.D.), Materials Science University of Arizona 1982 - 1984

Master's degree, Metallurgy University of Arizona 1978 - 1982

Bachelor's degree, Metallurgical Engineering

Master of Business Administration (MBA), Business Administration and Management, General University of Arizona 1984 - 1987

Doctor of Philosophy (Ph.D.), Materials Science University of Arizona 1982 - 1984

Master's degree, Metallurgy University of Arizona 1978 - 1982

Bachelor's degree, Metallurgical Engineering

Donald Zipperian

view sourceName / Title

Company / Classification

Phones & Addresses

Vice-president

PACE TECHNOLOGIES CORPORATION

Mfg Industrial Organic Chemicals · Mfg Electrical Equipment/Supplies

Mfg Industrial Organic Chemicals · Mfg Electrical Equipment/Supplies

3601 E 34 St, Tucson, AZ 85713

1802 W Grant Rd, Tucson, AZ 85745

4790 Avenida Del Cazador, Tucson, AZ 85718

(520)8826598

1802 W Grant Rd, Tucson, AZ 85745

4790 Avenida Del Cazador, Tucson, AZ 85718

(520)8826598

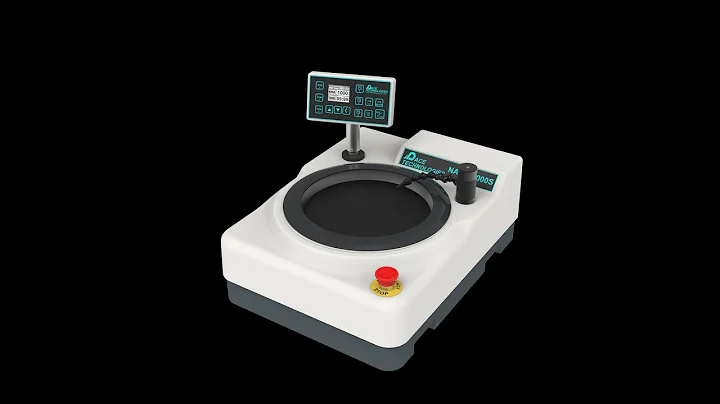

President/ceo

NANOFINISH CORPORATION

8290 W Sahara Ave #160, Las Vegas, NV 89117

3601 E 34 St, Tucson, AZ 85713

4790 Avenida Del Cazador, Tucson, AZ 85718

3601 E 34 St, Tucson, AZ 85713

4790 Avenida Del Cazador, Tucson, AZ 85718

Principal

Pace Technologies

Nonclassifiable Establishments · Professional Organization

Nonclassifiable Establishments · Professional Organization

4790 E Avenida Del Cazador, Tucson, AZ 85718

(520)8826598, (520)2997279

(520)8826598, (520)2997279

President, Treasurer

Nanofinish

Mfg Abrasive Products

Mfg Abrasive Products

4790 E Avenida Del Cazador, Tucson, AZ 85718

Manager

ZIPPS INVESTMENT, LLC

Investor

Investor

4790 E Avenida Del Cazador, Tucson, AZ 85718

Us Patents

-

Corrosion Inhibitors And Methods For Magnetic Media And Magnetic Head Read-Write Device

view source -

US Patent:20060227458, Oct 12, 2006

-

Filed:Apr 8, 2005

-

Appl. No.:11/102905

-

Inventors:Donald Zipperian - Tucson AZ, US

-

Assignee:Pace Technologies Corporation - Tucson AZ

-

International Classification:G11B 5/10

-

US Classification:360128000

-

Abstract:Corrosion inhibitor compositions and methods useful in finishing, grinding, cleaning, and other operations involving materials used in the manufacture of magnetic reading/writing heads and magnetic storage media. The compositions contain at least one azole compound, are soluble in ethylene glycol, propylene glycol, glycerin and isopropyl alcohol, and provide corrosion resistance for magnetic metals, such as manganese, iron, nickel, and cobalt, as well as magnetic alloys and magnetic layered stacks containing manganese, iron, nickel, cobalt, chromium, iridium, ruthenium, zirconium, and tantalum.

-

Froth Flotation Apparatus With Water Recovery And Method

view source -

US Patent:43942580, Jul 19, 1983

-

Filed:Jun 25, 1981

-

Appl. No.:6/276809

-

Inventors:Donald E. Zipperian - Tucson AZ

-

Assignee:The Diester Concentrator Co., Inc. - Fort Wayne IN

-

International Classification:B03D 124

-

US Classification:209170

-

Abstract:The invention relates to the concentration of particulate matter by froth flotation and in particular to improvements leading to the conservation of water. The apparatus includes an upstanding flotation compartment adapted to contain a relatively quiescent body of aqueous pulp. Aqueous pulp is introduced into and float fraction is collected from the upper portion of the flotation compartment, and hydraulic and aeration compartments are disposed near the bottom of the flotation compartment for aerating the water therein. A water-collecting compartment connected to the bottom of the hydraulic and aeration compartments is adapted to receive water from the latter. A tailings-discharge duct centrally of the flotation compartment extends through the hydraulic, aeration and water collection compartments to discharge fluidized tailings. The water-collecting compartment is connected to drain into a water-replenishing reservoir having an outlet leading to a pump which in turn is connected back to the hydraulic and aeration compartments. The reservoir is adapted to receive other water from a suitable source.

-

Froth Flotation Apparatus

view source -

US Patent:50789210, Jan 7, 1992

-

Filed:Jul 12, 1990

-

Appl. No.:7/551932

-

Inventors:Donald E. Zipperian - Tucson AZ

-

Assignee:The Deister Concentrator Company, Inc. - Fort Wayne IN

-

International Classification:B01F 304

-

US Classification:261122

-

Abstract:A column flotation cell includes a fluid vessel, an exteriorly mounted microbubble generator, conduits for conducting a pressurized mixture of bubbles and liquid from the generator to the vessel, features for inhibiting the coalescence and enlargement of the bubbles prior to their introduction into the vessel, and an arrangement for introducing the bubble/liquid mixture into the vessel and for distributing the mixture uniformly throughout the vessel cross-section. Coalescence and enlargement of the bubbles are inhibited by limiting the length of the mixture-conducting conduits, and by designing the conduits so as to provide a substantially uniform and continuous flow diameter. The uniform and continuous nature of the flow diameter reduces local disturbances of fluid flow which would otherwise occur at discontinuities in the flow path, tending to cause coalescence and enlargement of the bubbles. The inside diameter of the conduit on the downstream end is not greater than the inside diameter on the upstream end so as to maintain the pressure and velocity of the mixture flow substantially constant. A plurality of conduits are preferably used for conducting the mixture from the bubble generator to the vessel.

-

Mechanochemical Polishing Abrasive

view source -

US Patent:52288862, Jul 20, 1993

-

Filed:Aug 30, 1991

-

Appl. No.:7/753654

-

Inventors:Donald C. Zipperian - Tucson AZ

-

Assignee:Buehler, Ltd. - Lake Bluff IL

-

International Classification:B24D 300

-

US Classification:51293

-

Abstract:A mechanochemical polishing abrasive and a process for using the mechanochemical polishing abrasive to polish the surface of a hardened workpiece cheaply and efficiently. The mechanochemical polishing abrasive comprises a slurry of colloidal silica and a mechanical abrasive selected from one or more of the materials in the group comprising Fe. sub. 2 O. sub. 3, Fe. sub. 3 O. sub. 4, MgO, BaCO. sub. 3, CaCO. sub. 3, MnO. sub. 2, CeO, SiO. sub. 2, CeO. sub. 2, Cr. sub. 2 O. sub. 3, and Al. sub. 2 O. sub. 3.

-

Method And Apparatus For Generating Microbubbles In Froth Flotation Mineral Concentration Systems

view source -

US Patent:49717316, Nov 20, 1990

-

Filed:Dec 1, 1989

-

Appl. No.:7/444727

-

Inventors:Donald E. Zipperian - Tucson AZ

-

Assignee:Deister Concentrator Company, Inc. - Fort Wayne IN

-

International Classification:B01F 304

-

US Classification:261 81

-

Abstract:A method and apparatus for generating microbubbles in a flowing liquid stream for use in a froth flotation system. The system utilizes a microbubble generator having a tubular housing with an inlet end and an outlet end. Located coaxially within the housing is an inner member with an elongated, tapered, exterior surface. A porous tubular sleeve is mounted between the housing and the inner member coaxially therewith to define with the cylindrical interior surface of the housing an elongated air chamber of annular cross section. The porous sleeve has a cylindrical inner surface that defines with the exterior surface of the inner member an elongated liquid flow chamber of thin, annular cross section. An aqueous liquid is supplied to the liquid flow chamber at a relatively high flow rate and air under pressure is supplied to the air chamber so that air is forced radially inwardly through the porous sleeve to be diffused in the form of microbubbles in the flowing stream.

-

Concentration Of Ore By Flotation With Solutions Of Aqueous Dithiophosphates And Thionocarbamate As Collector

view source -

US Patent:40409503, Aug 9, 1977

-

Filed:Jun 6, 1975

-

Appl. No.:5/584685

-

Inventors:Donald Edwin Zipperian - Tuscon AZ

James Allen Jones - Tuscon AZ

Thomas Brian Buza - Tuscon AZ -

Assignee:American Cyanamid Company - Stamford CT

-

International Classification:B03D 102

-

US Classification:209166

-

Abstract:A process for flotation of copper sulfide values from copper bearing ores wherein a collector that comprises an aqueous solution of a salt of a dialkyl thiophosphate and an N-alkyl O-alkyl thionocarbamate dissolved therein, is employed.

-

Flotation Separating System

view source -

US Patent:46171134, Oct 14, 1986

-

Filed:Dec 18, 1984

-

Appl. No.:6/683008

-

Inventors:John A. Christophersen - Fort Wayne IN

Fred J. Marquardt - Fort Wayne IN

Donald E. Zipperian - Tucson AZ -

Assignee:Deister Concentrator Company, Inc. - Fort Wayne IN

-

International Classification:B03D 114

-

US Classification:209170

-

Abstract:Improvements in flotation separating systems of the type employing small rising air bubbles to induce ascension of certain types of particles in a flotation compartment while other particle types descend toward the bottom of the compartment include a bubble passing, particle blocking barrier forming the bottom of the compartment separating the compartment from a source of air bubbles while allowing the introduction of a uniform distribution of air bubbles into the compartment in the form of a gently sloped conical plate having a plurality of aerated water passing apertures and an array of downwardly extending pocket forming baffles for limiting bubble migration along the slope of the lower plate surface. The baffles are generally configured as radially and circumferentially extending baffle portions. Particles are prevented from passing through the plate apertures by introducing additional sealing water flowing toward the barrier from beneath by way of a plurality of inwardly extending water supply pipes opening downwardly at their innermost ends.

-

Method And Apparatus For Concentration Of Minerals By Froth Flotation Using Dual Aeration

view source -

US Patent:47357096, Apr 5, 1988

-

Filed:Jan 21, 1987

-

Appl. No.:7/005916

-

Inventors:Donald E. Zipperian - Tucson AZ

-

Assignee:Deister Concentrator Company, Inc. - Fort Wayne IN

-

International Classification:B03D 1024

-

US Classification:209164

-

Abstract:A froth flotation system for separating a mineral fraction from an aqueous pulp containing a mixture of mineral and gangue particles. The aqueous pulp is supplied to a pulp-filled vessel (or column) wherein a froth is formed on the surface of the pulp and collected in a launder. Gas bubbles are introduced into the pulp in the vessel by two different means to generate the froth. In accordance with one means, water is aspirated into a stream of pressurized gas (air) to form a stream of aerated water which is injected into the lower portion of the pulp-filled vessel. In accordance, the other means, a second stream of pressurized gas (air), is sparged through a porous wall of one or more micro-diffusers located within the vessel. The dual means for generating bubbles produces a significantly higher level of mineral separation than can be achieved from either means separately.

Youtube

Mylife

Elaine Zipperian Albuque...

view sourceDonald Zipperian Donald Zipperian Donald Zipperian Denise Zipperian Debbie Zipperian

Elizabeth Zipperian Fran...

view sourceEleanor Zipperian Elaine Zipperian Donald Zipperian Donald Zipperian Donald Zipperian

Classmates

Dald Zipperian Tucs AZ ...

view sourceDonald Zipperian 1978 graduate of Santa Rita High School in Tucson, AZ is on Classmates.com. See pictures, plan your class reunion and get caught up with Donald and other high ...

Santa Rita High School, T...

view sourceGraduates:

Donald Zipperian (1974-1978),

Jacqui Daniels (1982-1986),

Larry Gillis Larry Gillis (1983-1987)

Jacqui Daniels (1982-1986),

Larry Gillis Larry Gillis (1983-1987)

Get Report for Donald E Zipperian from Tucson, AZ, age ~89