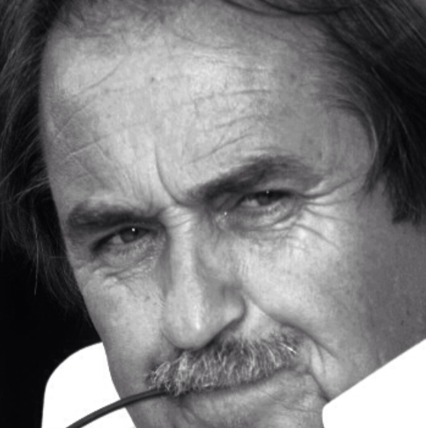

Francis C Miller

age ~58

from Clinton, MD

- Also known as:

-

- Francis Charles Miller

- Frank Miller

- Phone and address:

-

6111 Bradley Ln, Clinton, MD 20735

(571)2747304

Francis Miller Phones & Addresses

- 6111 Bradley Ln, Clinton, MD 20735 • (571)2747304

- Johnstown, PA

- Bolling AFB, DC

- Riverside, CA

- Brookhaven, NY

Us Patents

-

Dual Feed Hydrocyclone And Method Of Separating Aqueous Slurry

view source -

US Patent:46523634, Mar 24, 1987

-

Filed:Nov 1, 1984

-

Appl. No.:6/667127

-

Inventors:Francis G. Miller - Ligonier PA

-

International Classification:B04C 504

-

US Classification:209211

-

Abstract:A duel feed hydrocyclone is proposed for separating an aqueous slurry of particles into a bottom stream which contains the heavy/large particles and a top stream which contains the light/small particles. The aqueous slurry is delivered through a common feed conduit and is divided into two initially parallel horizontally spaced-apart streams. The first stream enters the cylindrical chamber of the hydrocyclone through a side wall opening near the top thereof; the second feed stream is delivered around the outer surface of the cylindrical chamber and is introduced into the cylindrical chamber through a second side wall opening, remote from the first side wall opening. The heavy/large particles of the slurry descend adjacent to the inner wall of the hydrocyclone in helical paths which are distinct from one another. Some particle segregation occurs in the second passageway prior to introduction of the second partial feed stream into the hydrocyclone.

-

Froth Flotation Separation Method And Apparatus

view source -

US Patent:46134301, Sep 23, 1986

-

Filed:Dec 10, 1984

-

Appl. No.:6/679981

-

Inventors:Francis G. Miller - Ligonier PA

-

International Classification:B03D 102

-

US Classification:209167

-

Abstract:An improved froth flotation installation for separating solid particles from an aqueous slurry by delivering a stream of the aqueous slurry directly into a vortex chamber along with a supply of bubble-forming gas. The kinetic energy of the slurry creates necessary froth bubbles, and provides mechanical agitation of the contents of a froth flotation separation zone upon discharge from the bottom of the vortex chamber. In multi-zone froth flotation installations, the direction of flow of the aqueous slurry of unrecovered solid particles is deliberately changed at least twice between a first froth flotation zone and a last froth flotation zone to improve solids-froth contact and to minimize the possibility of particles adopting a short circuit path through the installation. Multiple froth flotation zones are serviced by a single slurry pump in a preferred embodiment.

-

Method For Recovering Fine Clean Coal

view source -

US Patent:48029769, Feb 7, 1989

-

Filed:Jan 4, 1988

-

Appl. No.:7/140564

-

Inventors:Francis G. Miller - Ligonier PA

-

International Classification:B03B 700

B03B 900

B03D 102 -

US Classification:209 12

-

Abstract:A heavy medium low-specific gravity method for recovering coarse clean coal within a size range of about +28 m and fine clean coal and coal-bearing particles within a size range of -28 x Om from a raw coal feed wherein heavy medium is recovered as a substantially clean product which can be recycled in the heavy medium system. In the method a raw coal feed containing coal, shale and other impurities within a size range of about 3. 81 cm. times. 0 is mixed withi a heavy medium to produce a slurry of low specific gravity between about 1. 27 and 1. 70. The slurry is treated in at least one cyclone to separate an overflow product containing substantially all coal and coal-bearing particles from an underflow product containing all shale and sulfur-bearing rejects. The overflow product is treated on standard equipment to separate coarse coal from fine coal and heavy medium. The coarse coal is recovered as a usable product.

-

Froth Flotation Separation Apparatus

view source -

US Patent:46134310, Sep 23, 1986

-

Filed:Oct 15, 1985

-

Appl. No.:6/787263

-

Inventors:Francis G. Miller - Ligonier PA

-

International Classification:B03D 102

-

US Classification:209169

-

Abstract:An improved froth flotation installation for separating solid particles from an aqueous slurry by delivering a stream of the aqueous slurry directly into a vortex chamber along with a supply of bubble-forming gas. The kinetic energy of the slurry creates necessary froth bubbles, and provides mechanical agitation of the contents of a froth flotation separation zone upon discharge from the bottom of the vortex chamber. In multi-zone froth flotation installations, the direction of flow of the aqueous slurry of unrecovered solid particles is deliberately changed at least twice between a first froth flotation zone and a last froth flotation zone to improve solids-froth contact and to minimize the possibility of particles adopting a short circuit path through the installation. Multiple froth flotation zones are serviced by a single slurry pump in a preferred embodiment.

-

Vortex Chamber Aerator

view source -

US Patent:46068228, Aug 19, 1986

-

Filed:Nov 1, 1984

-

Appl. No.:6/667128

-

Inventors:Francis G. Miller - Ligonier PA

-

International Classification:B01F 304

-

US Classification:2102212

-

Abstract:A vortex chamber aerator is provided with a split feed conduit whereby the liquid feed is introduced into the vortex chamber through two opposed passageways to provide more even distribution of the liquid currents within the vortex chamber. This results in reduced wear in the vortex chamber and more importantly presents a uniform discharge pattern of the liquid and entrained gas bubbles.

Resumes

Francis Miller

view sourceLocation:

United States

Francis Miller

view sourceLocation:

United States

Experienced It Executive

view sourceLocation:

Lafayette, Louisiana

Industry:

Information Technology and Services

Francis Miller

view sourceLocation:

United States

Francis Miller

view sourceLocation:

United States

Francis Miller

view sourceLocation:

United States

Francis Miller

view sourceLocation:

United States

Name / Title

Company / Classification

Phones & Addresses

President

Riddell Management Services Inc

Management Services

Management Services

329 Sugarland Run Dr, Dulles, VA 20164

(703)4062833

(703)4062833

Secretary, Treasurer

MILTECH ANALYTICAL SERVICES, INC

Engineers and Consultants

Engineers and Consultants

115 S Market St, Ligonier, PA 15658

PO Box 501, Ligonier, PA 15658

(724)2385695

PO Box 501, Ligonier, PA 15658

(724)2385695

F & B MILLER, LLC

Director

J. F. CAVANAUGH CO., INC

SOUTH ATLANTIC FISHERIES, LLC

Isbn (Books And Publications)

Arbitration: Preliminary Publication of Recommendations & Survey on the Law and Practice of Arbitration in England & Wales Based on Extracts from A Critique of the Practicality of Arbitration

view sourceAuthor

Francis E. Miller

ISBN #

0951429507

Investor's Choice: Finding the Investment Broker That Will Make You Money

view sourceAuthor

Francis W. Miller

ISBN #

0759609624

Smart Investors: Picking the Right Stock Broker for Maximum Profits

view sourceAuthor

Francis W. Miller

ISBN #

0935016430

Man from the Valley: Memoirs of a Twentieth Century Virginian

view sourceAuthor

Francis P. Miller

ISBN #

0807811610

Classmates

Francis Miller

view sourceSchools:

Blythe Township High School New Philadelphia PA 1949-1953

Community:

Mary Kenna

Francis Ronald Miller

view sourceSchools:

Stowe High School Mckees Rocks PA 1953-1957

Community:

Nancy Hogan, James O'laughlin, Thaddeus Kiesnowski, Lawrence Eggie

Francis Miller

view sourceSchools:

Grasso Southeast Vocational Technical High School Groton CT 1987-1991

Community:

James Farmer, Holly Zeches, Lawrence Irish, Cynthia Lounsbury, Susan Ponta

Francis Miller (Mitchell)

view sourceSchools:

Benton High School Benton MS 1957-1961

Community:

George Smith, Mary Epps, Charles Hood

Francis Miller (Wood)

view sourceSchools:

Glennallen High School Glennallen AK 1999-2003

Community:

Anne Strode, Melinda Smith, Connie Mills, Cheri Lancaster, Mary Littlechief

Francis Miller

view sourceSchools:

Whitcomb High School Bethel VT 1980-1984

Community:

Haruhiko Davis, Lori Salls, Mary Campbell, Charlotte Fisk

Francis Miller

view sourceSchools:

Edgerton Elementary School Clio MI 1975-1980

Community:

Rebecka Vigus

Francis Miller

view sourceSchools:

Benton Harbor High School Benton Harbor MI 1980-1984

Community:

Jeffrey Elliott, Talitha Johnson, Barbara Epps

Youtube

Flickr

Myspace

Googleplus

Francis Miller

Education:

Harlingen south

Francis Miller

Tagline:

Business consultant

Francis Miller

Francis Miller

Francis Miller

Francis Miller

Francis Miller

Francis Miller

Francis Miller

view source

Francis Miller

view source

Francis Miller

view source

Francis Miller

view source

Francis Miller

view source

Robert Francis Miller

view source

Francis Xavier Miller

view source

Mary Francis Miller

view sourceGet Report for Francis C Miller from Clinton, MD, age ~58