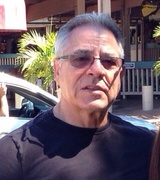

Fred Ofelio Garcia

age ~34

from Donora, PA

Fred Garcia Phones & Addresses

- 97 Kenric Ave, Donora, PA 15033 • (724)8230259

- 1157 Meldon Ave, Donora, PA 15033 • (412)4174347

Work

-

Position:Executive, Administrative, and Managerial Occupations

Education

-

Degree:Graduate or professional degree

Images

Emails

Specialities

Buyer's Agent • Listing Agent

License Records

Fred D Garcia

License #:

37 - Expired

Category:

Health Care

Issued Date:

Feb 17, 1986

Effective Date:

Jan 1, 1901

Expiration Date:

Jan 31, 1997

Type:

Certified Respiratory Therapist

Real Estate Brokers

Fred Garcia

view sourceSpecialties:

Buyer's Agent

Listing Agent

Listing Agent

Us Patents

-

Self-Actuating Vacuum Gas/Liquid Separator

view source -

US Patent:45003297, Feb 19, 1985

-

Filed:Apr 25, 1983

-

Appl. No.:6/488482

-

Inventors:Alan A. Campoli - Irwin PA

Fred Garcia - Donora PA -

Assignee:United States of America as represented by Secretary of the Interior - Washington DC

-

International Classification:B01D 1900

-

US Classification:55189

-

Abstract:A self-actuating gas/liquid separator which depends on the counterbalancing f the liquid in a closed container in excess of a certain height and the vacuum gas pressure for its actuation and operation. Primarily this invention was directed to the separation of water and methane gas after they are discharged from an inclined coal mine drainage bore hole. Basically, there are two inclined coaxial conduits, one inside the other, with the inner smaller conduit providing the path for the movement of the gas and the outer larger conduit the path for the liquid. Attached to the larger conduit, near its end remote from the source of gas and liquid to be separated, is a third conduit with a U-shaped section and a one-way liquid passing check valve. Liquids drain into the first and third conduits and the second conduit is operably subjected to a vacuum generating source. Eventually, as the liquids fill their conduit containers, there will come a time when the counterbalancing gas pressure created by the vacuum and the rising liquid level become unbalanced.

-

Portable Tester For Determining Gas Content Within A Core Sample

view source -

US Patent:57419590, Apr 21, 1998

-

Filed:Aug 9, 1996

-

Appl. No.:8/694574

-

Inventors:Fred Garcia - Donora PA

Steven J. Schatzel - Bethel Park PA -

Assignee:The United States of America as represented by the United States

Department of Energy - Washington DC -

International Classification:G01N 700

-

US Classification:73 1905

-

Abstract:A portable tester is provided for reading and displaying the pressure of a gas released from a rock core sample stored within a sealed container and for taking a sample of the released pressurized gas for chemical analysis thereof for subsequent use in a modified direct method test which determines the volume of gas and specific type of gas contained within the core sample. The portable tester includes a pair of low and high range electrical pressure transducers for detecting a gas pressure; a pair of low and high range display units for displaying the pressure of the detected gas- a selector valve connected to the low and high range pressure transducers, a selector knob for selecting gas flow to one of the flow paths; control valve having an inlet connection to the sealed container, and outlets connected to: a sample gas canister, a second outlet port connected to the selector valve means for reading the pressure of the gas from the sealed container to either the low range or high range pressure transducers, and a connection for venting gas contained within the sealed container to the atmosphere. A battery is electrically connected to and supplies the power for operating the unit. The pressure transducers, display units, selector and control valve means and the battery is mounted to and housed within a protective casing for portable transport and use.

Resumes

Fred Garcia

view sourceLocation:

United States

Fred Garcia

view sourceLocation:

United States

Flickr

Plaxo

Fred Garcia

view sourceOffices in Colorado and Washington State

Fred Garcia

view sourceToronto, Ontario

Fred Garcia

view sourceOffice Solutions

Fred Garcia

view source

Fred Garcia

view source

Fred Occena Garcia

view source

Fred Pipo Garcia

view source

Fred Garcia

view source

Fred Garcia

view source

Fred Victoria Garcia

view source

Fred Rick GArcia

view sourceGoogleplus

Fred Garcia

Work:

Ace tubular - Contractual (2010)

Education:

St. louise de marilac - Accountancy

Relationship:

Married

About:

Married to karizma garcia, grade three teacher of sorsogon east central school

Bragging Rights:

Has a wonderful son, another on the way

Fred Garcia

Work:

Titan Aviation (1999)

Education:

University of Miami - Fan

Relationship:

Married

Tagline:

Family Man

Fred Garcia

Work:

Newmont Mining - Process Maintence (5)

Education:

Great Basin community colledge

Fred Garcia

Fred Garcia

Tagline:

Me gusta TODO, musica, alcoholismo, sexo desenfrenado, fiestas etc.

Fred Garcia

Fred Garcia

Fred Garcia

Classmates

Fred Norris (Garcia)

view sourceSchools:

Nixon High School Laredo TX 1972-1976

Community:

Veronica Aleman, Sylvia Planer

Biography:

The photo shows me at Campwood, TX in the Texas hill country in Dec. 2007. I enjoy ...

Fred Garcia

view sourceSchools:

Laguna Madre Christian Academy South Padre Island TX 1978-1980

Community:

Trinity Brown, Loree Fimbers, Brittany Gold, Erskine Cousineau, Slim Shadee

Fred Garcia

view sourceSchools:

Santa Rosa High School Santa Rosa TX 1989-1993

Community:

Catarino Cipriano

Fred Garcia

view sourceSchools:

Myra Green Middle School Raymondville TX 1999-2003

Community:

Lorenzo Hoyos, Dora Loza, Nora Diaz, Esteban Reyes, Dorothy Ramirez

Fred Garcia

view sourceSchools:

Weld Central High School Keenesburg CO 1991-1995

Community:

Rudy Solis, Carla Adams

Fred Garcia

view sourceSchools:

Ash Fork High School Ash Fork AZ 1973-1977

Community:

Timothy Griffin, Jan Emery, Lois Johnson, Rita Williams

Fred Garcia

view sourceSchools:

Holtville High School Holtville CA 1964-1968

Community:

Matthew Warren, Lillian Waldroop, Gene Luker

Myspace

Youtube

Get Report for Fred Ofelio Garcia from Donora, PA, age ~34