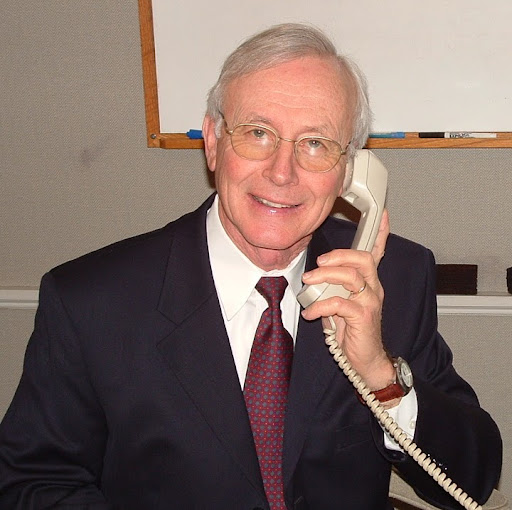

Gerald Hall

age ~55

from Brookfield, IL

- Also known as:

-

- John Thompson

- Geist Boo

- Phone and address:

- 4537 Maple Ave APT 2, Brookfield, IL 60513

Gerald Hall Phones & Addresses

- 4537 Maple Ave APT 2, Brookfield, IL 60513

- Winston, GA

- Cleveland, OH

- South Point, OH

- 15518 Montrose Ave, Cleveland, OH 44111

Isbn (Books And Publications)

License Records

Gerald Lee Hall

License #:

19081 - Expired

Category:

Cosmetology

Issued Date:

May 1, 1965

Effective Date:

Dec 31, 1971

Type:

Cosmetologist

Gerald Lowell Hall

License #:

63356 - Expired

Category:

Nursing Support

Issued Date:

Feb 5, 2004

Effective Date:

Jun 12, 2008

Type:

Nurse Aide

Name / Title

Company / Classification

Phones & Addresses

President

Hall Freight Brokers

Freight Forwarding

Freight Forwarding

14942 Wilco Dr, Homer Glen, IL 60491

(708)3017641

(708)3017641

President

South Island Water Ltd.

Trucking - Water Hauling

Trucking - Water Hauling

1324 Norwach Place, Sooke, BC V9Z 0Z7

(250)5165066

(250)5165066

President

South Island Water Ltd

Trucking - Water Hauling

Trucking - Water Hauling

(250)5165066

Owner

Am PM All Service Taxi

Taxicab Service · Taxicabs

Taxicab Service · Taxicabs

822 Liberty St, Concord Township, OH 44077

(440)2311976

(440)2311976

Partner

Gerald W EDD Hall

Individual/Family Services

Individual/Family Services

100 Professional Pl, Carrollton, GA 30117

(770)8301300

(770)8301300

Vice-President

CPUrx, Inc

Computer Related Consulting Srvcs

Computer Related Consulting Srvcs

1101 W Adams St #H, Chicago, IL 60607

(312)7330534

(312)7330534

Vice-President

Cpu Rx, Inc

Computer Related Consulting Srvcs

Computer Related Consulting Srvcs

1101 W Adams St, Chicago, IL 60607

Vice-President

Hall Brothers Inc

Meat Market

Meat Market

27040 Cook Rd, Cleveland, OH 44138

(440)2353262

(440)2353262

Us Patents

-

Flow Responsive Poppet Relief Valve

view source -

US Patent:39878147, Oct 26, 1976

-

Filed:Mar 17, 1975

-

Appl. No.:5/558751

-

Inventors:Gerald D. Hall - Joliet IL

-

Assignee:Caterpillar Tractor Co. - Peoria IL

-

International Classification:F16K 2500

-

US Classification:137469

-

Abstract:A flow responsive poppet relief valve includes a housing having an outlet chamber and an inlet passage opening thereon to define an annular valve seat therebetween, a spool disposed for axial movement in the housing and having a head with a conical nose portion thereon, a spring disposed intermediate the housing and the spool for biasing the conical nose portion axially closably against the valve seat and whereby the spool is axially openly moved away therefrom by a fluid in the inlet passage at a predetermined pressure, and an outwardly flared surface portion on the head for assuring that upon opening movement of the spool a relatively thin fluid stream is guided by the conical nose portion in axially relatively low force-transmitting impinging relation glancingly against the flared surface portion, and upon further opening movement of the spool a relatively thicker fluid stream is guided by the conical nose portion in axially relatively greater force-transmitting impinging relation against the flared surface portion, with the streams being deflectably diverted angularly outwardly therefrom to the outlet chamber, in order to assure a stable response and a relatively high degree of pressure regulation of the poppet relief valve.

-

Load Check With Mechanical Venting Means

view source -

US Patent:41678923, Sep 18, 1979

-

Filed:Apr 7, 1977

-

Appl. No.:5/785627

-

Inventors:John R. Cryder - Joliet IL

Gerald D. Hall - Joliet IL

Samuel G. Dunlap - Goodfield IL -

Assignee:Caterpillar Tractor Co. - Peoria IL

-

International Classification:F15B 1108

F15B 13042 -

US Classification:91445

-

Abstract:A hydraulic motor and control system therefor which includes a pump for delivering fluid to a control valve, the control valve having a Float position which connects a first end of the motor to a sump, a First position for applying fluid from the pump to power the motor in a first direction by delivering fluid to the first end of the motor via a flow path and a Second position in which the motor moves in a second and opposite direction. A conduit connects the control valve to the sump. A check valve is provided in the flow path which always allows flow therethrough towards the first end of the motor and normally blocks reverse flow therethrough and also a mechanism for opening the check valve to allow reverse flow therethrough responsive to operation of the control valve in the Float position and in the Second position.

-

Implement Circuit For Motor With Slow And Fast Dump

view source -

US Patent:41636287, Aug 7, 1979

-

Filed:May 9, 1977

-

Appl. No.:5/795036

-

Inventors:Gerald D. Hall - Joliet IL

Lloyd D. Swayze - Yorkville IL -

Assignee:Caterpillar Tractor Co. - Peoria IL

-

International Classification:E02F 387

-

US Classification:414699

-

Abstract:A loader vehicle includes a loading implement movable to a dump and a rack-back position by means of actuation of cylinders. The movement of the cylinders is provided by fluid control valves in turn operated by means which provide for both a slow dump and a fast dump movement of the implement, with fast dump movement initially selected being automatically changed to slow dump movement dependent on the position of the implement.

Lawyers & Attorneys

Gerald Hall - Lawyer

view sourceSpecialties:

Real Estate

ISLN:

1000380528

Admitted:

2002

University:

San Francisco Law School, San Francisco CA

Resumes

Gerald Hall Markham, IL

view sourceWork:

St. Colleta's of Illinois

Feb 2008 to 2000

Residential Aide United Parcel Service

May 2007 to Feb 2008

Package Handler

Feb 2008 to 2000

Residential Aide United Parcel Service

May 2007 to Feb 2008

Package Handler

Education:

South Suburban College

South Holland, IL

Sep 2007 to Dec 2009

Business Marketing Bremen High School

Midlothian, IL

May 2007

High School Diploma

South Holland, IL

Sep 2007 to Dec 2009

Business Marketing Bremen High School

Midlothian, IL

May 2007

High School Diploma

Gerald Hall Doraville, GA

view sourceWork:

Elster Meter Services

Cartersville, GA

May 2011 to Aug 2012

Production Worker Ryla Teleservices

Kenn

Jan 2007 to Oct 2009

Customer Care Representative

Cartersville, GA

May 2011 to Aug 2012

Production Worker Ryla Teleservices

Kenn

Jan 2007 to Oct 2009

Customer Care Representative

Education:

Georgia State University

Atlanta, GA

1999 to 2001

not completed in Film & Video Alabama State University

Montgomery, AL

1995 to 1999

Not completed in Communications Media

Atlanta, GA

1999 to 2001

not completed in Film & Video Alabama State University

Montgomery, AL

1995 to 1999

Not completed in Communications Media

Skills:

Microsoft Word, Microsoft publisher, Adobe photoshop, Windows, Editing & Script Writing.

Myspace

Googleplus

Gerald Hall

Lived:

Atlanta, Georgia

Work:

Different Places - Different titles (1986)

Tagline:

I am who I am.

Gerald Hall

Work:

Lifetime Financial Group - Owner (1970)

Relationship:

Married

Tagline:

Gerald Hall has over 35 years of experience helping clients make financial decisions about wealth preservation, estate planning, business succession strategies, retirement planning, education funding, portfolio management, financial risk management, special needs planning and charitable giving.

Gerald Hall

Gerald Hall

Gerald Hall

Gerald Hall

Gerald Hall

Gerald Hall

Flickr

Plaxo

Gerald R Hall

view sourceRetired

Classmates

Gerald White (Hall)

view sourceSchools:

Thomas Jefferson High School Richmond VA 1952-1956

Community:

Julian French, John Burton

Gerald Hall

view sourceSchools:

Robert E. Lee High School Staunton VA 1974-1978

Gerald Hall

view sourceSchools:

Stewart-Quitman High School Lumpkin GA 1955-1958

Community:

Eddie Cannon, Priscilla Brock, Leticia Houston

Gerald Hall

view sourceSchools:

Valley Point High School Dalton GA 1956-1960

Community:

Connie Mitchell, Kenneth Gordon, Bob Burchfield, Rhonda Scarbrough, Delford Jamison, Aileen Sharp

Gerald Hall

view sourceSchools:

Victory Christian Academy New Albany MS 1993-1997

Community:

Delay Castro, Amanda Ivy, Janet Moulin, Heidi Jones

Gerald Hall

view sourceSchools:

St. Paul High School St. Paul IN 1949-1953

Community:

Cary Gray, Patty Gill, Treva Lambert, Jonita Craig

Gerald Hall

view sourceSchools:

Windsor Oaks Elementary School Virginia Beach VA 1981-1985

Community:

Connie Cole, Debby Casciato, Ivan Hughes, Scott Alston, Debi Hassel

Youtube

Gerald Hall

view source

Gerald Grave Hall

view source

Gerald Dana Hall

view source

Gerald Jerry Hall

view source

Cnor Gerald Hall

view source

Gerald Geo Hall

view source

Gerald Hall

view source

Gerald L. Hall Jr.

view sourceGet Report for Gerald Hall from Brookfield, IL, age ~55