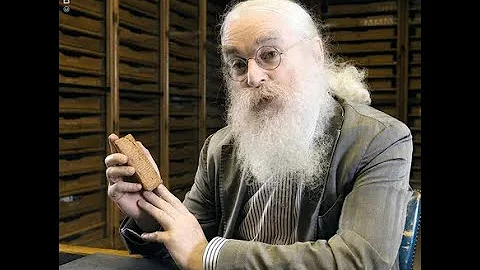

Irving W Potter

age ~77

from Portland, OR

- Also known as:

-

- Irving William Potter

- Irving N Potter

- Irving R Potter

- Ivring W Potter

- Irving E

- Phone and address:

-

5020 Downs View Ct, Portland, OR 97221

(503)2970129

Irving Potter Phones & Addresses

- 5020 Downs View Ct, Portland, OR 97221 • (503)2970129 • (503)2976973

- 1410 Kearney St, Portland, OR 97209

- 333 9Th Ave, Portland, OR 97209

- Cannon Beach, OR

- Beaverton, OR

- Gales Creek, OR

- Ashland, OR

- 5020 SW Downs View Ct, Portland, OR 97221 • (503)2976973

Work

-

Company:Josselson, potter & roberts

-

Address:425 Nw 10Th Ave Ste 306, Portland, OR 97209

-

Phones:(503)2281455

-

Position:Manager

-

Industries:Educational, Religious, and Charitable Trusts

Education

-

Degree:Associate degree or higher

Specialities

Real Estate Law • Finance • General Business Law • Environmental Law

Lawyers & Attorneys

Irving William Potter, Beaverton OR - Lawyer

view sourceAddress:

9400 Sw Beaverton Hillsdale Hwy Ste 131A, Beaverton, OR 97005

(503)2281455 (Office)

(503)2281455 (Office)

Licenses:

Washington - Active 1983

Irving W Potter, Beaverton OR - Lawyer

view sourceAddress:

Ste 131-A 9400 Sw Bvtn-Hlsdl Hwy, Beaverton, OR 97005

(503)2281455 (Office)

(503)2281455 (Office)

Licenses:

Oregon - Active 1974

Irving W. Potter, Beaverton OR - Lawyer

view sourceOffice:

Josselson & Potter

9400 S.w. Beaverton-Hillsdale Hwy., Ste. 131-A, Beaverton, OR

9400 S.w. Beaverton-Hillsdale Hwy., Ste. 131-A, Beaverton, OR

Specialties:

Real Estate Law

Finance

General Business Law

Environmental Law

Finance

General Business Law

Environmental Law

ISLN:

904345986

Admitted:

1974

University:

Claremont McKenna College, B.A.

Law School:

Willamette University, J.D.

Irving Potter, Portland OR - Lawyer

view sourceAddress:

425 Nw 10Th Ave, Portland, OR 97209

Phone:

(503)2281455 (Fax)

Specialties:

Business Law

Environmental Law

Real Estate Law

Environmental Law

Real Estate Law

Jurisdiction:

Oregon

Memberships:

Oregon State Bar

Name / Title

Company / Classification

Phones & Addresses

Owner

Josselson & Potter

Attorneys

Attorneys

9400 SW Beaverton Hillsdale Hwy, Beaverton, OR 97005

(503)2281455

(503)2281455

Manager

Josselson, Potter & Roberts

Educational, Religious, and Charitable Trusts

Educational, Religious, and Charitable Trusts

425 Nw 10Th Ave Ste 306, Portland, OR 97209

Owner

JOSSELSON & POTTER

Attorneys

Attorneys

9400 SW Beaverton Hillsdale Hwy #131-A, Beaverton, OR 97005

(503)2281455, (503)2280171

(503)2281455, (503)2280171

Manager

Fan Nevada LLC

9400 SW Beaverton Hillsdale Hwy, Beaverton, OR 97005

Manager

Josselson Potter & Roberts

Law Practice · Grantmaking Foundations

Law Practice · Grantmaking Foundations

425 NW 10 Ave STE 306, Portland, OR 97209

(503)2281455

(503)2281455

Real property

AS ARETE LLC

9400 SW Beaverton-Hillsidale Hwy, Beaverton, OR 97005

Governing, Governing Person

ASPEN PENNY LLC

9400 SW Beaverton Hillsdale Hwy STE 131A, Beaverton, OR 97005

9400 SW Beaverton - Hillsdale Hwy SUITE 131-A, Beaverton, OR 97005

9400 SW Beaverton - Hillsdale Hwy SUITE 131-A, Beaverton, OR 97005

GREGORY FUNDING LLC

9400 SW Beaverton-Hillsdale Hwy SUITE 131-A, Beaverton, OR 97005

124 W Capitol Ave SUITE 1900, Little Rock, AR 72201

124 W Capitol Ave SUITE 1900, Little Rock, AR 72201

Vehicle Records

-

Irving Potter

view source -

Address:5020 SW Downs Vw Ct, Portland, OR 97221

-

Phone:(503)2976973

-

VIN:JTDKN3DU0A1245482

-

Make:TOYOTA

-

Model:PRIUS

-

Year:2010

Resumes

Irving Potter

view sourceUs Patents

-

Process For Making A Particle Board

view source -

US Patent:39950034, Nov 30, 1976

-

Filed:Jan 14, 1974

-

Appl. No.:5/433272

-

Inventors:Edward Potter - Beaverton OR

Irving W. Potter - Beaverton OR

Robert M. Smyth - Lake Oswego OR -

Assignee:Dant & Russell, Inc. - Portland OR

-

International Classification:B29J 500

-

US Classification:264122

-

Abstract:A process for making a particle board of substantial continuous thickness utilizing any of a wide assortment of comminuted lignocellulosic materials. The particle board is prepared by mixing dried lignocellulosic particles with one or more thermosetting or thermoplastic adhesive binders in predetermined proportions, and placing a measured amount of the resultant mixture in an elongate mold where it is bonded together under the influence of pressure and heat. The mold includes a movable pressure plate forming the top of an enclosure within which the material is compressed to a predetermined thickness by pressure applied to the exterior of the plate. The thickness of the compressed mixture is substantial, so as to enable the production of particle board pieces having sufficient continuous solid thickness that they may be used for such applications as dimension lumber or railroad ties, or may be sawed into multiple thinner pieces for other applications such as siding. After the mixture in the mold has been compressed to the predetermined thickness, fasteners are attached for retaining the pressure plate in its compressed position. Thereafter the mold is taken from the press and transferred to an oven where its contents, still under pressure from the retained pressure plate, are baked or cured for an extended period of time and then allowed to cool, after which the pressure plate is removed from the mold permitting the removal of the resultant bonded particle board product.

Classmates

Irving Potter, Claremont,...

view sourceIrving Potter 1970 graduating class of Claremont McKenna College in Claremont, CA

Claremont McKenna College...

view sourceGraduates:

Irving Potter (1966-1970),

Andre Fleuriel (1976-1977),

Kheder Baykal (1995-1999),

Jeff Lokey (1991-1993),

John John Streidl (1989-1993)

Andre Fleuriel (1976-1977),

Kheder Baykal (1995-1999),

Jeff Lokey (1991-1993),

John John Streidl (1989-1993)

Keeleigh Potter, Irving, TX

view sourceKeeleigh Potter 1995 graduating class of Irving High School in Irving, TX

Youtube

Samantha Irving Potter N...

view sourceSamantha Irving Potter (Newcastle)

Search Names Samantha Irv...

view source

Samantha Irving Potter

view sourceGet Report for Irving W Potter from Portland, OR, age ~77