John W Roman

age ~86

from Atco, NJ

- Also known as:

-

- John William Roman

John Roman Phones & Addresses

- Atco, NJ

- Collingswood, NJ

- Mount Laurel, NJ

Lawyers & Attorneys

John J. Roman - Lawyer

view sourceLicenses:

New York - Currently registered 1989

License Records

John A Roman

License #:

E056488 - Active

Category:

Emergency medical services

Issued Date:

Jan 2, 2009

Expiration Date:

May 31, 2017

Type:

Contra Costa County EMS Agency

John C Roman Partner

License #:

NM029530A - Expired

Category:

Real Estate Commission

Type:

Broker Multi-Licensee-Standard

John E Roman

License #:

RS136447A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

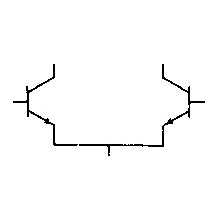

Us Patents

-

Modular Low Stress Package Technology

view source -

US Patent:8153474, Apr 10, 2012

-

Filed:Oct 13, 2010

-

Appl. No.:12/903761

-

Inventors:Craig J. Rotay - Audubon PA, US

John Ni - San Leandro CA, US

David Lam - San Carlos CA, US

David Lee DeWire - Superior CO, US

John W. Roman - Natick MA, US

Richard J. Ross - Moraga CA, US -

Assignee:STMicroelectronics, Inc. - Coppell TX

-

International Classification:H01L 21/52

-

US Classification:438107, 438108, 438118, 438128, 257E215

-

Abstract:A method of manufacturing a protected package assembly: providing a protective modular package cover in accordance with a modular design; selectively applying an adhesive to the cross member of each subassembly receiving section of the protective modular package cover that will receive a subassembly to form an adhesive layer of the protective modular package cover; encapsulating the one or more subassemblies in the subassembly receiving sections on the selectively applied adhesive layer to generate a protected package assembly; and controlling application of a distributed downward clamping force applied to the top surfaces of the subassemblies received by the protective modular package cover and useful for mounting the protected package assembly to a core through activation of fastener elements and cross members of the subassembly receiving sections.

-

Modular Low Stress Package Technology

view source -

US Patent:8283769, Oct 9, 2012

-

Filed:Oct 13, 2010

-

Appl. No.:12/903734

-

Inventors:Craig J. Rotay - Audubon PA, US

John Ni - San Leandro CA, US

David Lam - San Carlos CA, US

David Lee DeWire - Superior CO, US

John W. Roman - Natick MA, US

Richard J. Ross - Moraga CA, US -

Assignee:STMicroelectronics, Inc. - Coppell TX

-

International Classification:H01L 21/00

-

US Classification:257690, 257692, 257718, 257E21705, 257E23194, 257E23185, 257E23193, 257E33059

-

Abstract:A protective modular package cover has first and second fastening sections located at opposing first and second ends with one or more subassembly receiving sections disposed thereto and is configured to fasten the protective modular package cover to a core. Each fastening section has a foot surface located on a bottom surface of a fastening section and configured to make contact with the core, a mounting hole configured to receive a fastener, and a torque element. Each subassembly receiving section is configured to receive a subassembly and has a cross member formed along the underside of the protective modular package cover. Activation of the first torque element transfers a downward clamping force generated at the fastening element to a top surface of one or more subassemblies disposed in the one or more subassembly receiving sections via the cross member of each of the one or more subassembly receiving sections.

-

Modular Low Stress Package Technology

view source -

US Patent:8560104, Oct 15, 2013

-

Filed:Oct 13, 2010

-

Appl. No.:12/903772

-

Inventors:Craig J. Rotay - Audubon PA, US

John Ni - San Leandro CA, US

David Lam - San Carlos CA, US

David Lee DeWire - Superior CO, US

John W. Roman - Natick MA, US

Richard J. Ross - Moraga CA, US -

Assignee:STMicroelectronics, Inc. - Coppell TX

RJR Polymers, Inc. - Oakland CA -

International Classification:G06F 19/00

-

US Classification:700 98

-

Abstract:A method of designing a modular package: determining a package outline of a modular package assembly from package outline design data; determining seating plane and overall package length characteristics of the assembly from seating plane and package length design data; the design tool calculating minimum package height of the modular package assembly from the seating plane and package length design data; designing the dimensions and configuration of one or more subassemblies from subassembly design data; defining dimensions and configuration of a plurality of mechanical layers of a protective modular package cover given the defined package outline, the seating plane, overall package length, the minimum package height, and the subassemblies; defining an adhesive deposition strategy to join mechanical layers of the cover; designing the cover in accordance with the dimensions and configuration of the mechanical layers; and incorporating the assembly and the adhesive deposition strategy into a manufacturing assembly process.

-

Modular Low Stress Package Technology

view source -

US Patent:8639373, Jan 28, 2014

-

Filed:Oct 13, 2010

-

Appl. No.:12/903779

-

Inventors:Craig J. Rotay - Audubon PA, US

John Ni - San Leandro CA, US

David Lam - San Carlos CA, US

David Lee DeWire - Superior CO, US

John W. Roman - Natick MA, US

Richard J. Ross - Moraga CA, US -

Assignee:STMicroelectronics, Inc. - Coppell TX

RJR Polymers, Inc. - Oakland CA -

International Classification:G06F 19/00

-

US Classification:700 98

-

Abstract:A method of designing a desired modular package assembly: determining the configuration and dimensions of the assembly from received user input design data, the assembly having a protective modular package cover with first and second fastening sections, subassembly receiving sections disposed between the fastening sections and having a cross member formed along the underside of the protective modular package cover and configured to receive a subassembly, and one or more subassemblies to be received by the subassembly receiving sections; determining an adhesive deposition strategy for deposition of an adhesive layer to the cross members of the subassembly receiving sections sufficient to affix the top side of the subassemblies to the cross members on the underside of the subassembly receiving sections; and incorporating the configuration and dimensions of the modular package assembly and the adhesive deposition strategy into a manufacturing assembly process configured to manufacture the modular package assembly.

-

Modular Low Stress Package Technology

view source -

US Patent:20110084376, Apr 14, 2011

-

Filed:Oct 13, 2010

-

Appl. No.:12/903752

-

Inventors:Craig J. Rotay - Audubon PA, US

John Ni - San Leandro CA, US

David Lam - San Carlos CA, US

David Lee DeWire - Superior CO, US

John W. Roman - Natick MA, US

Richard J. Ross - Moraga CA, US -

Assignee:STMICROELECTRONICS, INC. - Carollton TX

RJR POLYMERS, INC. - Oakland CA -

International Classification:H01L 23/495

H01L 23/32 -

US Classification:257690, 257685, 257E23194

-

Abstract:A protective modular package assembly with one or more subassemblies, each having a base element, a sidewall element coupled to the base element, and a semiconductor device disposed within and coupled to the sidewall element and the base element; a protective modular package cover having fastening sections located at opposing ends of the cover, torque elements disposed on the opposing ends and configured to fasten the cover to a core, and subassembly receiving sections disposed between the fastening sections with each subassembly receiving section operable to receive a subassembly and having a cross member along the underside of the cover; and an adhesive layer configured to affix subassemblies to respective subassembly receiving sections. The torque elements are configured to transfer a downward clamping force generated at the fastening elements to a top surface of the subassemblies via the cross member of each of the one or more subassembly receiving sections.

Medicine Doctors

John William Roman

view sourceName / Title

Company / Classification

Phones & Addresses

Owner

Ad Mark Network Inc

4 Saw Buck Cir, Horsham, PA 19044

(215)2353270

(215)2353270

Principal

John A Roman

Business Services at Non-Commercial Site

Business Services at Non-Commercial Site

915 E Abington Ave, Ardsley, PA 19038

Executive Vice-President

Bryn Mawr Trust Company

Commercial Bank · State Commercial Bank Commercial Bank · State Commercial Bank · Commercial Banking

Commercial Bank · State Commercial Bank Commercial Bank · State Commercial Bank · Commercial Banking

801 W Lancaster Ave, Rosemont, PA 19010

(610)5251700, (215)5251700, (215)5262450, (800)5548969

(610)5251700, (215)5251700, (215)5262450, (800)5548969

Principle

John Meehan & Son

Hospital & Health Care · Paving Company

Hospital & Health Care · Paving Company

9301 Krewstown Rd, Philadelphia, PA 19115

(215)6737800

(215)6737800

Advertising Director, Executive Of Sales

General Asphalt Paving Co of Philadelphia

Water/Sewer/Utility Construction Highway/Street Construction

Water/Sewer/Utility Construction Highway/Street Construction

9301 Krewstown Rd, Philadelphia, PA 19115

(215)6772626

(215)6772626

J & J ROMAN LLC

TOTAL HOME MAINTENANCE, INC

President

QUAKER FUNDS, INC

Investment Advisory Service · Financial Advisor · Investment Banking & Securities Dealing

Investment Advisory Service · Financial Advisor · Investment Banking & Securities Dealing

309 Technology Dr, Malvern, PA 19355

1180 Swedesford Rd, Berwyn, PA 19312

(610)6402870, (610)4552200, (610)4552222, (800)2208888

1180 Swedesford Rd, Berwyn, PA 19312

(610)6402870, (610)4552200, (610)4552222, (800)2208888

Plaxo

John Roman

view sourceVP & Business Unit Deputy Director of Contracts at... Past: Contracts Administrator at DynCorp International, Contracts Associate at Marasco Newton...

John Roman

view sourceJ A International S A

JOHN M. ROMAN

view sourceWesleyan Academy

Classmates

John Roman

view sourceSchools:

St. Maries High School St. Maries ID 1962-1966

Community:

Lara Johns, Nora Miller, Rori Porter

John Roman

view sourceSchools:

Hazlehurst High School Hazlehurst MS 1979-1983

Community:

Melvin Dumas

John Howard (Roman)

view sourceSchools:

Stowe Township High School Stowe PA 1962-1966

Community:

Michael Trapuzzano, Frank Patterson, Donna Lysko

John Roman

view sourceSchools:

Gladstone High School Gladstone MI 1992-1996

John Roman

view sourceSchools:

Adrian Elementary School South Euclid OH 1989-1992, St. Gregory the Great School South Euclid OH 1992-1998

Community:

Kevin Dearden, Mark Dymond, Andrea Cancilla, Evelyn Gray, Vincent Crawford

John Roman

view sourceSchools:

H.B. Zachry Middle School San Antonio TX 1995-1999

Community:

Autumn Walker, Jennifer Ray, Paula Cruz, Susannah Hartmann, David Hanaway

John Roman

view sourceSchools:

Holy Spirit High School Absecon NJ 1982-1986

Community:

Richard Dodson, James Fadigan, George Batten, Aileen Steelman

John Roman Adrian Solde

view source

John Roman Dolor Rodriguez

view source

John Arnulf Roman

view source

Robert John Roman

view source

John Roman Acosta

view source

John Roman Tagle

view source

John Robert Roman

view source

Robert John Roman III

view sourceYoutube

Myspace

John Roman

view source

John Roman

view sourceFlickr

Googleplus

John Roman

Work:

University of Western Ontario - Researcher (2010)

Education:

University of Western Ontario - Chemistry

John Roman

Work:

Dept. Of Defense

Education:

Grantham University, Midwood H.S.

John Roman

Work:

UMB - Business Analyst (2013)

Education:

Nova Southeastern University - Business

John Roman

Work:

O'Dell Oil - Asst. Manager (2005)

John Roman

Relationship:

Single

About:

Hello Dear,John Hear...

Tagline:

Honesty is the best policy

John Roman

John Roman

Tagline:

HW - SW Design Engineer

John Roman

News

Uber's Crime Report Is ‘Highly Alarming,’ Says a Criminologist

view source- Still, one criminologist said that, unlike West, he was surprised by the numbers contained in the Uber safety report, and not in a good way. Its highly alarming, says John Roman, a senior fellow at NORC at the University of Chicago, a social science research organization.

- Date: Dec 06, 2019

- Category: Business

- Source: Google

Hillary Clinton's claim that the 'highest per capita number' of crime guns in New York come from Vermont

view source- It doesnt matter how many people live there. The issue is, how many gun dealers are there that are contributing to violence in New York, said John Roman, senior fellow in the Justice Policy Center at the Urban Institute. Roman, who has worked with New York officials over gun violence and gun laws

- Date: Apr 12, 2016

- Source: Google

FACT CHECK: Clinton's latest gun-law broadside on Sanders

view source- John Roman, a senior fellow at the Urban Institute, said Clintons analysis was statistically correct but focused on the wrong numbers. It doesnt matter how many people live in Vermont. It matters how many bad gun dealers there are, Roman said.

- Date: Apr 12, 2016

- Source: Google

Verdict in Trayvon Martin case leaves blacks wondering, where do we go from ...

view source- A little less than 3 percent of black-on-white homicides taking place in circumstances similar to the Trayvon Martin case are ruled to be justified, according to a study by John Roman, a senior fellow at the Urban Institute. But when the races are reversed and whites kill blacks, the percentage of c

- Date: Jul 16, 2013

- Source: Google

DC on pace for fewer than 100 homicides in 2012

view source- "If you asked people what would happen first, there'll be a thousand murders in D.C. in a year or there'll be less than a hundred, I think virtually everybody would have said there would be 1,000," said John Roman, a senior fellow at the Washington-based Urban Institute.

- Date: Nov 23, 2012

- Source: Google

Get Report for John W Roman from Atco, NJ, age ~86