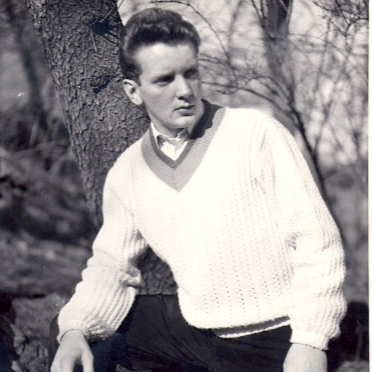

Joseph Angela Lyons

age ~82

from Tewksbury, MA

- Also known as:

-

- Joseph A Lyons

- Joseph J Lyons

- Joseph D Lyons

- Jos Lyons

- Joe Lyona

- Lyons Jos

Joseph Lyons Phones & Addresses

- Tewksbury, MA

- Newfield, ME

- Burlington, MA

- 4 Senator Rd, Woburn, MA 01801 • (781)9373289

- Andover, MA

- Northborough, MA

- Amesbury, MA

Lawyers & Attorneys

Joseph Lyons - Lawyer

view sourceSpecialties:

Business

Corporate Counsel

Health Law

Government/Administrative Law

Corporate Counsel

Health Law

Government/Administrative Law

ISLN:

1000192496

Admitted:

2002

Joseph Lyons - Lawyer

view sourceSpecialties:

Employment Law

Litigation

Litigation

ISLN:

915592362

Admitted:

2000

University:

Harvard University, A.B., 1993

Law School:

University of Pennsylvania, J.D., 1999

Real Estate Brokers

Joseph Lyons

view sourceSpecialties:

Buyer's Agent

Listing Agent

Listing Agent

License Records

Joseph D Lyons

License #:

41764 - Active

Category:

Dual Towing Operator(IM)/VSF Employee

Expiration Date:

Jan 27, 2018

Joseph Lyons

Address:

Woburn, MA 01801

License #:

4170 - Expired

Issued Date:

Jun 12, 1998

Expiration Date:

Dec 31, 2001

Type:

Mental Health Counselor

Joseph M Lyons

License #:

26473 - Expired

Issued Date:

Jun 23, 1972

Expiration Date:

Jun 30, 2000

Type:

Mechanical Engineer

Joseph M Lyons

License #:

RI004074 - Expired

Category:

Real Estate Commission

Type:

Real Estate Instructor

Medicine Doctors

Dr. Joseph Lyons, Worcester MA - MD (Doctor of Medicine)

view sourceSpecialties:

Internal Medicine

Address:

21 Cedar St, Worcester, MA 01609

(508)7992663 (Phone), (508)7539779 (Fax)

(508)7992663 (Phone), (508)7539779 (Fax)

Certifications:

Internal Medicine, 1952

Awards:

Healthgrades Honor Roll

Languages:

English

Name / Title

Company / Classification

Phones & Addresses

Sem Analyst

Smarter Travel Media LLC

Periodicals: Publishing, or Publishing and Pr...

Periodicals: Publishing, or Publishing and Pr...

500 Rutherford Ave # 102, Boston, MA 02129

President, Principal

SPIN350 CREATIVE, INC

Communication Services

Communication Services

61 Central Ave, Hyde Park, MA 02136

Hyde Park, MA 02136

Hyde Park, MA 02136

CONTAMINATION CONTROL PRODUCTS, LLC

HOPLON INCORPORATED

Principal

Lyon's

Business Services at Non-Commercial Site · Commercial Printing

Business Services at Non-Commercial Site · Commercial Printing

30 Edwin St, Quincy, MA 02171

Manager

The Shaw Group Inc

Engineering Services · Fabricated Pipe & Pipe Fitting Mfg

Engineering Services · Fabricated Pipe & Pipe Fitting Mfg

100 Technology Ctr Dr, Stoughton, MA 02072

1 Beacon Ln, Canton, MA 02021

(781)2975800, (617)5895111, (617)5892156

1 Beacon Ln, Canton, MA 02021

(781)2975800, (617)5895111, (617)5892156

Assistant Director Career Center

Virginia Commonwealth University

Medical Doctor's Office College/University · College/University · Health/Allied Services · Academic Research · Vocational School · General Hospital College/University · Beauty Shop

Medical Doctor's Office College/University · College/University · Health/Allied Services · Academic Research · Vocational School · General Hospital College/University · Beauty Shop

(804)8286600, (804)8289716, (804)8286347, (804)8280183

President

HEAD INJURY PROGRAMS, INC

184 Pleasantview Ave, Braintree, MA 02184

Us Patents

-

Apparatus And Method For Picking A Single Printing Plate From A Stack Of Printing Plates

view source -

US Patent:6675712, Jan 13, 2004

-

Filed:Apr 5, 2002

-

Appl. No.:10/117412

-

Inventors:Thomas Marincic - Tyngsboro MA

Aron Mirmelshteyn - Marblehead MA

Joseph Lyons - Wilmington MA -

Assignee:Agfa Corporation - Wilmington MA

-

International Classification:B65H 354

-

US Classification:101477, 101483, 271106

-

Abstract:An apparatus and method for picking a single printing plate from a stack of printing plates. The apparatus includes a plurality of suction cups, a peeler, a drive system for displacing the suction cups and the peeler against the surface of the top printing plate on the stack, a vacuum source for supplying a vacuum to the suction cups to secure the suction cups against the surface of the top printing plate, and a system for rotatably displacing the suction cups relative to the peeler to peel a portion of the top printing plate off of the stack. The center line of rotation of the displacing system is located at a contact point between the peeler and the surface of the top printing plate. This prevents any relative motion of the top printing plate against the next, underlying printing plate on the stack during the peeling operation.

-

Apparatus And Method For Peeling A Printing Plate From A Stack Of Plates

view source -

US Patent:6880462, Apr 19, 2005

-

Filed:Jan 3, 2002

-

Appl. No.:10/039901

-

Inventors:Thomas Marincic - Tyngsboro MA, US

Aron Mirmelshteyn - Marblehead MA, US

Joseph Lyons - Wilmington MA, US -

Assignee:Agfa Corporation - Wilmington MA

-

International Classification:B41L047/14

B65H005/08 -

US Classification:101477, 101479, 101483, 271105, 4147966, 4147972

-

Abstract:An apparatus and method for supporting and feeding printing plates in an imaging system. The apparatus includes a vacuum system for picking up an edge of a top printing plate from a stack of printing plates, and a peeling system including a pair of rotatable belts, a plurality of plate feed beams attached to, and extending between, the pair of rotatable belts, and a drive system for rotating the pair of rotatable belts to displace the plurality of plate feed beams between the top printing plate and an underlying printing plate in the stack of printing plates, thereby peeling the top printing plate from the stack of printing plates.

-

Plate Cassette For Platesetter

view source -

US Patent:20030188985, Oct 9, 2003

-

Filed:Apr 5, 2002

-

Appl. No.:10/117749

-

Inventors:Steven DaSilva - Reading MA, US

Thomas Marincic - Tyngsboro MA, US

Donald Richardson - Atkinson NH, US

Robert Olenio - North Andover MA, US

Joseph Lyons - Wilmington MA, US -

Assignee:Agfa Corporation

-

International Classification:B65D085/48

-

US Classification:206/456000, 206/216000

-

Abstract:A plate cassette for a platesetter comprises a tray that receives and stores stacks of plates. Side frame members are located on opposed sides of the tray. These side frame members have tracks that engage with wheels of another plate cassette and wheels that engage with tracks of still another plate cassette. In this way, cassettes may be stacked and stored, one on top of each other. The wheel engagement strategy, between cassettes, however, allows individual cassettes to be rolled out, enabling access to the plate stack in the selected cassette's tray. A suction leak groove is formed in a surface of the tray. This provides for a suction leakage path for a picker, when the picker must grab typically the last plate in the stack and the plate is not full-sized. The suction grabbers that do not directly grab the plate do not adhere to the tray, allowing the picker to separate the plate from the tray. A slip sheet removal groove is also provided.

-

Plate Cassette Loader For Platesetter

view source -

US Patent:20030190225, Oct 9, 2003

-

Filed:Apr 5, 2002

-

Appl. No.:10/117482

-

Inventors:Thomas Marincic - Tyngsboro MA, US

Aron Mirmelshteyn - Marblehead MA, US

Joseph Lyons - Wilmington MA, US

Matthew Kowalczyk - Somerville MA, US -

Assignee:Agfa Corporation

-

International Classification:B25J005/02

-

US Classification:414/758000, 414/765000, 414/766000, 414/782000, 414/773000, 414/795800

-

Abstract:A plate cassette loader for a platesetter comprises a cassette holder for receiving a cassette, containing a stack of plates. A cassette inverter then rotates this cassette to a feed position in which the plates can be fed into the imaging engine of the platesetter. In this way, the somewhat unwieldy process of loading plates into the imaging engine is handled by the cassette inverter, in combination with the fact that the stack of plates, contained in the cassette, can be loaded in one step, rather than requiring the feeding of individual plates by a dedicated operator.

-

Slip Sheet Capture Mechanism And Method Of Operation

view source -

US Patent:20050046105, Mar 3, 2005

-

Filed:Aug 26, 2003

-

Appl. No.:10/649560

-

Inventors:Donald Richardson - Atkinson NH, US

Joseph Lyons - Wilmington MA, US

Steven DaSilva - Reading MA, US -

Assignee:Agfa Corporation - Wilmington MA

-

International Classification:B65H005/02

-

US Classification:271272000

-

Abstract:A substrate manager for a substrate exposure machine is used, in one example, as a platesetter. As such, it comprises a substrate storage system, containing one or more stacks of substrates, such as plates in one implementation. A substrate picker is provided for picking substrates from the stack of substrates. The substrates are then handed to a transfer system that conveys the substrates to an imaging engine. According to the invention, a substrate inverter system is also provided. This system inverts the substrates from being imaging or emulsion side down to emulsion side up in the present implementation. This allows plates, for example, which are stored emulsion side down in cassettes to be flipped to an emulsion side up orientation, and then transferred, using the substrate transfer system to the imaging engine. This flipping process has two advantages. First, the plates can be emulsion side up during the transfer. This prevents any damage to the sensitive plate emulsions. Moreover, the plates, now in an emulsion side up configuration are in the right orientation for being installed on the outside of a drum on an external drum imaging system, as is common in many platesetters. Also, the plates are picked from the non emulsion side. Thus the system is less sensitive to emulsion formulation changes. A slip sheet capture mechanism is also provided to pass slip sheets separating the plates to a storage location.

-

Media Input Selector And Method

view source -

US Patent:55117430, Apr 30, 1996

-

Filed:Nov 23, 1993

-

Appl. No.:8/156459

-

Inventors:Edward P. Kozlowsky - Sanford ME

Joseph R. Lyons - Wilmington MA -

Assignee:Miles, Inc. - Wilmington MA

-

International Classification:B65H 1910

B65H 2002 -

US Classification:242526

-

Abstract:A method and apparatus automatically switches from one web media type to another, using a single drive roller to access and drive one of two web media supply cassettes mounted within an imaging system. A gear motor and eccentric shaft position and load the drive roller against either of two driven rollers. The media is nipped between the drive roller and one of the driven rollers and is advanced by the drive roller into the imaging system as needed. To switch media supply cassettes, the media is cut beyond the drive roller. The media is then drawn back into the supply cassette to free the media path for the alternate media to advance from the other of the two media supply cassettes.

-

Count Down System For Recording Charts

view source -

US Patent:49252143, May 15, 1990

-

Filed:Jun 9, 1987

-

Appl. No.:7/060130

-

Inventors:Donald R. Hazelton - Chester NH

Paul J. Latka - West Springfield MA

Joseph N. Lyons - Springfield MA

Eugene H. Spender - North Billerica MA -

Assignee:Hewlett-Packard Company - Palo Alto CA

-

International Classification:B42D 1500

B42D 1900

G03B 104

G11B 1506 -

US Classification:283 62

-

Abstract:Signs or indicia are printed or otherwise formed at locations on the last portion of a recording strip that indicate the amount of recording that can occur after each location. The indication can be in the number of pages, length of paper or time.

Resumes

Joseph Lyons

view sourceIndustry:

Military

Work:

Us Navy Aug 2008 - Nov 2018

Usn

Us Department of Homeland Security Aug 2008 - Nov 2018

Dhs

Usn

Us Department of Homeland Security Aug 2008 - Nov 2018

Dhs

Education:

Wallenpaupack Area High School 2014 - 2014

Wallenpaupack Area High School 2004 - 2008

Wallenpaupack Area High School 2004 - 2008

Joseph Lyons

view source

Joseph Lyons

view source

Joseph Lyons

view source

Joseph Lyons

view source

Joseph T Lyons

view sourceSkills:

Customer Service

Photoshop

Outlook

Powerpoint

Event Planning

Research

Public Speaking

Microsoft Word

Microsoft Excel

Teaching

Microsoft Office

Windows

Editing

Budgets

Strategic Planning

English

Nonprofits

Teamwork

Leadership

Team Leadership

Photoshop

Outlook

Powerpoint

Event Planning

Research

Public Speaking

Microsoft Word

Microsoft Excel

Teaching

Microsoft Office

Windows

Editing

Budgets

Strategic Planning

English

Nonprofits

Teamwork

Leadership

Team Leadership

President Land Owner At Land Owner + People Rehab.

view sourcePosition:

President Land Owner-Belize at Land Owner + People Rehab.

Location:

Greater Boston Area

Industry:

Venture Capital & Private Equity

Work:

Land Owner + People Rehab. since 1990

President Land Owner-Belize

President Land Owner-Belize

Interests:

Belize , Toledo District , sustainable development , selling to appropriate party only .

Joseph Lyons

view sourceLocation:

United States

Isbn (Books And Publications)

Experience:an Introduction to a Personal Psychology: An Introduction to a Personal Psychology

view sourceAuthor

Joseph Lyons

ISBN #

0060441380

Ecology of the Body: Styles of Behavior in Human Life

view sourceAuthor

Joseph Lyons

ISBN #

0822307103

Plaxo

Joseph Lyons

view sourceClermont, Fl

Joseph L. Lyons

view source

Joseph Lyons Jr.

view source

Joseph Lyons

view source

Joseph J Lyons

view source

Joseph Jl Lyons

view source

Joseph Lyons

view source

Joseph R. Lyons Jr.

view source

Joseph Leslie Lyons

view sourceYoutube

Googleplus

Joseph Lyons

Lived:

Boston, MA, NYC, N.Y., Canoga Park,, CA, CT, Hartford, Farmington, Danbury

Work:

B'Way Theatre, Music Publishing

Education:

RHMS Boston, Professional Theatre School NYC - Acting, Dance

Relationship:

Married

Bragging Rights:

Married to my best friend Elaine, 3 great children and 10 wonderful grandchildren

Joseph Lyons

Work:

Schneider National - Support Shift Operations (2004)

Education:

University of Wisconsin-Platteville - Philosophy

Joseph Lyons

Joseph Lyons

Joseph Lyons

Joseph Lyons

Tagline:

Why Ya Smiling

Joseph Lyons

Joseph Lyons

Myspace

Classmates

Joseph Lyons

view sourceSchools:

Adamsville High School Adamsville TN 1979-1983

Community:

Walter Stevens, Debra Walton, Heidi Strawn

Joseph Lyons

view sourceSchools:

Natalia High School Natalia TX 1995-1999

Community:

Wayne Blanchard, Joe Linehan, Rick Pinner, Nena Mcmillan

Joseph Lyons

view sourceSchools:

Holy Ghost Preparatory School Bensalem PA 1982-1986

Community:

Thomas Flynn, Regina Haas, Roy Horan, Bob Kustra, Donna Lewandowski

Joseph Lyons

view sourceSchools:

Lincoln Junior High School Plymouth IN 2001-2005

Community:

David Weedling, Benita Dickson, Angela Banks, Martha Avery

Joseph Lyons

view sourceSchools:

Bergen County Technical High School Hackensack NJ 1979-1983

Community:

June Teale

Joseph Lyons

view sourceSchools:

Hackensack High School Hackensack NJ 1969-1973

Community:

Karen Parciasepe, Richard Ferraro, Philip Osoff

Joseph Lyons

view sourceSchools:

Church Point High School Church Point LA 1987-1991

Community:

John Landry, Zoeann Higginbotham, Charles Labbe

Joseph Lyons

view sourceSchools:

Valhalla High School Valhalla NY 1965-1969

Community:

George Mauk, John Struth, Karen Rende, Russell Paulmann

Flickr

Get Report for Joseph Angela Lyons from Tewksbury, MA, age ~82