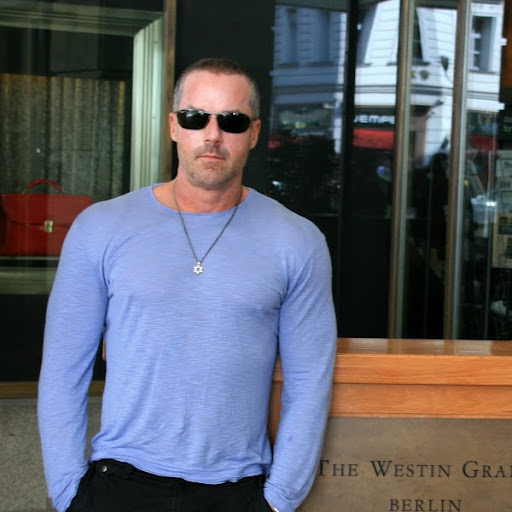

Kevin C Baucom

age ~65

from Winter Garden, FL

- Also known as:

-

- Kevin V Baucom

- Kevin Bauchom

Kevin Baucom Phones & Addresses

- Winter Garden, FL

- 2001 White Cloud St NE, Albuquerque, NM 87112 • (505)9747499

- 5336 Lucille Dr, Albuquerque, NM 87111 • (505)2756604

- Tampa, FL

- Armada, MI

- Bernalillo, NM

- Hillsboro Bch, FL

- 2001 White Cloud St NE, Albuquerque, NM 87112

Work

-

Position:Professional/Technical

Us Patents

-

Method Of Making Alinsb By Metal-Organic Chemical Vapor Deposition

view source -

US Patent:60711094, Jun 6, 2000

-

Filed:Feb 24, 1999

-

Appl. No.:9/256819

-

Inventors:Robert M. Biefeld - Albuquerque NM

Andrew A. Allerman - Albuquerque NM

Kevin C. Baucom - Albuquerque NM -

Assignee:Sandia Corporation - Albuquerque NM

-

International Classification:C23C 1618

-

US Classification:42525534

-

Abstract:A method for producing aluminum-indium-antimony materials by metal-organic chemical vapor deposition (MOCVD). This invention provides a method of producing Al. sub. X In. sub. 1-x Sb crystalline materials by MOCVD wherein an Al source material, an In source material and an Sb source material are supplied as a gas to a heated substrate in a chamber, said Al source material, In source material, and Sb source material decomposing at least partially below 525. degree. C. to produce Al. sub. x In. sub. 1-x Sb crystalline materials wherein x is greater than 0. 002 and less than one.

-

Infrared Emitting Device And Method

view source -

US Patent:56256353, Apr 29, 1997

-

Filed:Nov 28, 1994

-

Appl. No.:8/345160

-

Inventors:Steven R. Kurtz - Albuquerque NM

Robert M. Biefeld - Albuquerque NM

L. Ralph Dawson - Albuquerque NM

Arnold J. Howard - Albuquerque NM

Kevin C. Baucom - Albuquerque NM -

Assignee:Sandia Corporation

-

International Classification:H01S 319

-

US Classification:392 45

-

Abstract:An infrared emitting device and method. The infrared emitting device comprises a III-V compound semiconductor substrate upon which are grown a quantum-well active region having a plurality of quantum-well layers formed of a ternary alloy comprising InAsSb sandwiched between barrier layers formed of a ternary alloy having a smaller lattice constant and a larger energy bandgap than the quantum-well layers. The quantum-well layers are preferably compressively strained to increase the threshold energy for Auger recombination; and a method is provided for determining the preferred thickness for the quantum-well layers. Embodiments of the present invention are described having at least one cladding layer to increase the optical and carrier confinement in the active region, and to provide for waveguiding of the light generated within the active region. Examples have been set forth showing embodiments of the present invention as surface- and edge-emitting light emitting diodes (LEDs), an optically-pumped semiconductor laser, and an electrically-injected semiconductor diode laser. The light emission from each of the infrared emitting devices of the present invention is in the midwave infrared region of the spectrum from about 2 to 6 microns.

Resumes

Kevin Baucom

view source

Kevin Baucom

view sourceLocation:

United States

Name / Title

Company / Classification

Phones & Addresses

Managing

K & A Machine, LLC

Myspace

Kevin Baucom

view source

Kevin Baucom

view source

Kevin Baucom

view source

Kevin Baucom

view sourcePlaxo

Kevin M. Baucom

view sourceAttorney at Galloway, Johnson, Tompkins, Burr & Sm...

Googleplus

Kevin Baucom

Kevin Baucom

Kevin Baucom

Kevin Baucom

Youtube

Get Report for Kevin C Baucom from Winter Garden, FL, age ~65