Michael L Sherrard

age ~76

from Los Altos, CA

- Also known as:

-

- Michael Leslie Sherrard

- Michael Fede Christine Sherrard

- Mike L Sherrard

- Michael L Sherrad

- Michael L Sherrar

- Phone and address:

-

72 Doud Dr, Los Altos, CA 94022

(650)9412537

Michael Sherrard Phones & Addresses

- 72 Doud Dr, Los Altos Hills, CA 94022 • (650)9412537

- 1704 Orr Ct, Los Altos, CA 94024

- 1744 Orr Ct, Los Altos, CA 94024

- Bend, OR

- San Jose, CA

- Fremont, CA

- San Francisco, CA

- Hayward, CA

- Santa Clara, CA

- Salem, OR

- Mountain View, CA

Isbn (Books And Publications)

London Capital Group Limited (Formerly British Bangladesh Trust Limited): Investigation under Section 165(B) of the Companies Act 1948 Report

view sourceAuthor

Michael Sherrard

ISBN #

0115121277

Resumes

Associate Broker At Solid Source Realty

view sourceLocation:

Groraum Atlanta und Umgebung

Industry:

Immobilien

Insurance Sales & Management At Hayes, Ultey & Hedgspeth

view sourceLocation:

Louisville, Kentucky und Umgebung

Industry:

Versicherungswesen

Associate Pastor At Journey Church

view sourceLocation:

Groraum Atlanta und Umgebung

Industry:

Religse Einrichtungen

Michael Sherrard

view source

Specialist It Development At Nationwide Insurance

view sourceLocation:

Des Moines und Umgebung, Iowa

Industry:

Versicherungswesen

Lawyers & Attorneys

Michael Sherrard - Lawyer

view sourceOffice:

Sherrard Kuzz LLP, Employment & Labour Lawyers

Specialties:

Acquisitions, Divestitures and Restructurings

Advising the Multinational and Multi-Jurisdictional Employer

Attendance Management

Canada Industrial Relations Board Proceedings

Collective Agreement Administration

Collective Bargaining

Construction Labour Relations

Employee Relations

Employee Screening and Hiring

Employment Contracts

Employment Standards

Executive Compensation

Grievance Arbitration

Human Rights

Injunctive Court Proceedings and Judicial Review

Interest Arbitration

Management Training

Mediation

Occupational Health and Safety

Ontario Labour Relations Board Proceedings

Pay Equity

Privacy

Responding to Union Organizing and Applications for Certification

Sale or Closure

Strike or Lock-Out

Workplace Audits

Workplace Investigations

Workplace Safety and Insurance

Wrongful Dismissal Litigation

Advising the Multinational and Multi-Jurisdictional Employer

Attendance Management

Canada Industrial Relations Board Proceedings

Collective Agreement Administration

Collective Bargaining

Construction Labour Relations

Employee Relations

Employee Screening and Hiring

Employment Contracts

Employment Standards

Executive Compensation

Grievance Arbitration

Human Rights

Injunctive Court Proceedings and Judicial Review

Interest Arbitration

Management Training

Mediation

Occupational Health and Safety

Ontario Labour Relations Board Proceedings

Pay Equity

Privacy

Responding to Union Organizing and Applications for Certification

Sale or Closure

Strike or Lock-Out

Workplace Audits

Workplace Investigations

Workplace Safety and Insurance

Wrongful Dismissal Litigation

ISLN:

900976900

Admitted:

1992

University:

University of New Brunswick, B.Ed., 1987

Law School:

University of New Brunswick, LL.B., 1990

Michael L. Sherrard, Los Altos CA - Lawyer

view sourceOffice:

72 Doud Dr, Los Altos, CA

ISLN:

918868648

Admitted:

1978

University:

Massachusetts Institute of Technology, B.S.E.E.

Law School:

University of Denver, J.D.

Michael Sherrard - Lawyer

Us Patents

-

Apparatus For Cleaning And Drying Substrates

view source -

US Patent:6746544, Jun 8, 2004

-

Filed:Oct 25, 2001

-

Appl. No.:10/046423

-

Inventors:Boris Fishkin - San Carlos CA

Michael Sherrard - Los Altos CA -

Assignee:Applied Materials Inc. - Santa Clara CA

-

International Classification:B08B 300

-

US Classification:134 30, 134 26, 134 34, 134 36, 134 37, 134 32, 134902

-

Abstract:A method and apparatus for cleaning, rinsing and Marangoni drying substrates is provided. A line of fluid is sprayed along a substrate surface forming an air/fluid interface line, and a line of drying vapor is supplied to the interface line to achieve Marangoni drying. Thus, a large portion of the substrate is simultaneously dried. A preferred apparatus employs a tank of cleaning and/or rinsing fluid. Above the tank fluid a source of rinsing fluid directs rinsing fluid to the surface of a substrate forming a meniscus on the substrate surface as the substrate is lifted from the cleaning fluid, and a drying vapor source directs drying vapor to the meniscus. The drying vapor lowers the surface tension of the meniscus, inducing a Marangoni flow of rinsing fluid from the substrates surface, and thereby drying the substrate. The cleaning fluid tank has a substrate receiving and cleaning portion and a substrate rinsing portion. The rinsing fluid source and the drying vapor source are enclosed by a drying enclosure above the rinsing portion of the tank.

-

Apparatus For Cleaning And Drying Substrates

view source -

US Patent:7252098, Aug 7, 2007

-

Filed:Sep 22, 2003

-

Appl. No.:10/667855

-

Inventors:Boris Fishkin - San Carlos CA, US

Michael Sherrard - Los Altos CA, US -

Assignee:Applied Materials, Inc. - Santa Clara CA

-

International Classification:B08B 7/04

B08B 3/04

B08B 3/10 -

US Classification:134 66, 134 61, 134184, 134902

-

Abstract:A method and apparatus for cleaning, rinsing and Marangoni drying substrates is provided. A line of fluid is sprayed along a substrate surface forming an air/fluid interface line, and a line of drying vapor is supplied to the interface line to achieve Marangoni drying. Thus, a large portion of the substrate is simultaneously dried. A preferred apparatus employs a tank of cleaning and/or rinsing fluid. Above the tank fluid a source of rinsing fluid directs rinsing fluid to the surface of a substrate forming a meniscus on the substrate surface as the substrate is lifted from the cleaning fluid, and a drying vapor source directs drying vapor to the meniscus. The drying vapor lowers the surface tension of the meniscus, inducing a Marangoni flow of rinsing fluid from the substrate's surface, and thereby drying the substrate. The cleaning fluid tank has a substrate receiving and cleaning portion and a substrate rinsing portion. The rinsing fluid source and the drying vapor source are enclosed by a drying enclosure above the rinsing portion of the tank.

-

Apparatus For Cleaning And Drying Substrates

view source -

US Patent:7718011, May 18, 2010

-

Filed:Aug 6, 2007

-

Appl. No.:11/834657

-

Inventors:Boris Fishkin - San Carlos CA, US

Michael Sherrard - Los Altos CA, US -

Assignee:Applied Materials, Inc. - Santa Clara CA

-

International Classification:B08B 3/04

B08B 5/00

B08B 7/04 -

US Classification:134 18, 134 1, 134 13, 134 26, 134 30, 134 32, 134 34, 134 37, 134 61, 134 66, 134 952, 134 31, 134184, 134902

-

Abstract:A method and apparatus for cleaning, rinsing and Marangoni drying substrates is provided. The invention includes spraying a line of fluid to a substrate, thereby creating an air/fluid interface line on the substrate; supplying a line of drying vapors to the air/fluid interface line, thereby creating a Marangoni drying effect along the air/fluid interface line; and moving the substrate relative to the air/fluid line. Numerous other aspects are provided.

-

Apparatus For Cleaning And Drying Substrates

view source -

US Patent:20060260653, Nov 23, 2006

-

Filed:Jul 31, 2006

-

Appl. No.:11/497445

-

Inventors:Boris Fishkin - San Carlos CA, US

Michael Sherrard - Los Altos CA, US -

International Classification:B08B 3/00

-

US Classification:134026000, 134094100, 134095200, 134095300, 134030000

-

Abstract:A method and apparatus for cleaning, rinsing and Marangoni drying substrates is provided. A line of fluid is sprayed along a substrate surface forming an air/fluid interface line, and a line of drying vapor is supplied to the interface line to achieve Marangoni drying. Thus, a large portion of the substrate is simultaneously dried. A preferred apparatus employs a tank of cleaning and/or rinsing fluid. Above the tank fluid a source of rinsing fluid directs rinsing fluid to the surface of a substrate forming a meniscus on the substrate surface as the substrate is lifted from the cleaning fluid, and a drying vapor source directs drying vapor to the meniscus. The drying vapor lowers the surface tension of the meniscus, inducing a Marangoni flow of rinsing fluid from the substrate's surface, and thereby drying the substrate. The cleaning fluid tank has a substrate receiving and cleaning portion and a substrate rinsing portion. The rinsing fluid source and the drying vapor source are enclosed by a drying enclosure above the rinsing portion of the tank. Thus, substrate loading, cleaning, rinsing, drying and unloading are performed with at least partial overlap in time.

-

Apparatus For Cleaning And Drying Substrates

view source -

US Patent:63288141, Dec 11, 2001

-

Filed:Mar 26, 1999

-

Appl. No.:9/280118

-

Inventors:Boris Fishkin - San Carlos CA

Michael Sherrard - Los Altos CA -

Assignee:Applied Materials, Inc. - Santa Clara CA

-

International Classification:B08B 304

B08B 500

B08B 704 -

US Classification:134 30

-

Abstract:A method and apparatus for cleaning, rinsing and Marangoni drying substrates is provided. A line of fluid is sprayed along a substrate surface forming an air/fluid interface line, and a line of drying vapor is supplied to the interface line to achieve Marangoni drying. Thus, a large portion of the substrate is simultaneously dried. A preferred apparatus employs a tank of cleaning and/or rinsing fluid. Above the tank fluid a source of rinsing fluid directs rinsing fluid to the surface of a substrate forming a meniscus on the substrate surface as the substrate is lifted from the cleaning fluid, and a drying vapor source directs drying vapor to the meniscus. The drying vapor lowers the surface tension of the meniscus, inducing a Marangoni flow of rinsing fluid from the substrate's surface, and thereby drying the substrate. The cleaning fluid tank has a substrate receiving and cleaning portion and a substrate rinsing portion. The rinsing fluid source and the drying vapor source are enclosed by a drying enclosure above the rinsing portion of the tank.

Myspace

Flickr

Michael Sherrard

view sourceFriends:

Angela Vanmeter, Don Heckman III, Alisha Polly, Shane Ray

Michael J. Sherrard

view sourceFriends:

Kieron Sherrard, Fran Breen, Mark Costigan, Joan Hansen, Callum Smith

John Michael Sherrard

view source

Benjamin Michael Sherrard

view sourceFriends:

Karen Simmons, Craig Smith, Mike Leung, Rebecca Babcock, T Roy Taylor

Patrick Paul Michael Sher...

view sourceClassmates

University of New Brunswi...

view sourceGraduates:

Michael Sherrard (1983-1990),

Julie Arnott (1997-2000),

Martina Quapp (1991-1993),

Stacey Mcgee (1999-2001),

Gisele Leblanc (1975-1978)

Julie Arnott (1997-2000),

Martina Quapp (1991-1993),

Stacey Mcgee (1999-2001),

Gisele Leblanc (1975-1978)

Bloomfield High School, B...

view sourceGraduates:

Phillip Cummins (1965-1969),

Michael Lorimer (1974-1978),

Gabrielle Hartley (1988-1991),

Mike Sherrard (1984-1988),

Brian Kirchoff (1980-1984)

Michael Lorimer (1974-1978),

Gabrielle Hartley (1988-1991),

Mike Sherrard (1984-1988),

Brian Kirchoff (1980-1984)

Googleplus

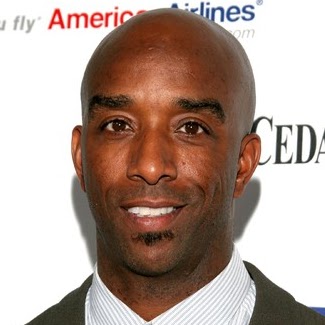

Michael Sherrard

Lived:

Calabasas, CA

Chico, CA

Foster City, CA

Hackensack, NJ

Aurora, CO

Bel Air, CA

Malibu, CA

Manhattan Beach, CA

Carrollton, TX

Chico, CA

Foster City, CA

Hackensack, NJ

Aurora, CO

Bel Air, CA

Malibu, CA

Manhattan Beach, CA

Carrollton, TX

Work:

Viking Capital

Education:

University of California, Los Angeles

Bragging Rights:

Super Bowl champ!

Michael Sherrard

Lived:

Los Altos, CA

Michael Sherrard

Michael Sherrard

Michael Sherrard

Youtube

Get Report for Michael L Sherrard from Los Altos, CA, age ~76