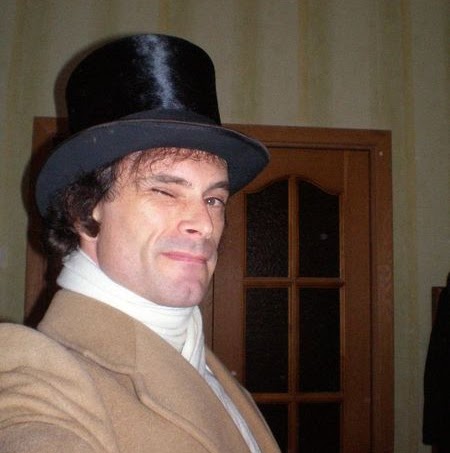

Paul J Spangler

age ~54

from Medina, OH

- Also known as:

-

- Paul J Pangler

- Charles Snyder

- Chas Snyder

Paul Spangler Phones & Addresses

- Medina, OH

- Wadsworth, OH

- 3768 Fairway Park Dr, Akron, OH 44321

- 3776 Fairway Park Dr, Akron, OH 44321

- 968 Snowfall Spur, Akron, OH 44313

- 968TH Snowfall Spur, Akron, OH 44313

- Fairlawn, OH

- Cortland, OH

- Canton, OH

- Stow, OH

- Sebastian, FL

- 212 Brixton Way, Wadsworth, OH 44281

Work

-

Company:Virginia alcohol beverage controlJan 2005

-

Position:Security officer

Education

-

School / High School:Appalachian State University- Boone, NCAug 1990

-

Specialities:education

Name / Title

Company / Classification

Phones & Addresses

Owner

Drummond Corp

Plastics Products

Plastics Products

Po Box 389, Mantua, OH 44021

Website: drummondcorp.com

Website: drummondcorp.com

PK INVESTORS LLC

Vice-President, President

Drummond Corp

Mechanical or Industrial Engineering · Mfg Fabricated Plastics

Mechanical or Industrial Engineering · Mfg Fabricated Plastics

14990 Berkshire Way, Middlefield, OH 44062

PO Box 389, Mantua, OH 44021

14990 Berkshire Industrial Pkwy, Middlefield, OH 44062

(440)8349660

PO Box 389, Mantua, OH 44021

14990 Berkshire Industrial Pkwy, Middlefield, OH 44062

(440)8349660

EXECUTIVE CONSULTING, INC

Canton, OH

Vehicle Records

-

Paul Spangler

view source -

Address:212 Brixton Way, Wadsworth, OH 44281

-

VIN:WDBRF92H97F917425

-

Make:MERCEDES-BENZ

-

Model:C-CLASS

-

Year:2007

Resumes

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Quality Assurance Specialist

view sourceWork:

Quality Assurance Specialist

Paul Spangler

view sourceLocation:

United States

Us Patents

-

Integral Electrical Connector And Method For Making Same

view source -

US Patent:43712290, Feb 1, 1983

-

Filed:Jun 20, 1980

-

Appl. No.:6/161380

-

Inventors:Paul J. Spangler - Novelty OH

Robert C. Koslo - Mentor OH -

Assignee:ETC, Incorporated - Bedford Heights OH

-

International Classification:H01R 420

-

US Classification:339223R

-

Abstract:An electrical connector progressively made from a one piece blank has a reinforced wire barrel, integral strain relief ferrule, and an internal wire ramp therebetween. The reinforced wire barrel includes nested cylindrical walls having side edges contacting opposite surfaces of an offset web extending between and interconnecting the two cylindrical walls.

-

Separable Funnel Guide And Crimping Die Assembly

view source -

US Patent:40646246, Dec 27, 1977

-

Filed:Jun 16, 1976

-

Appl. No.:5/696638

-

Inventors:Paul Joseph Spangler - Novelty OH

-

Assignee:International Telephone and Telegraph Corporation - New York NY

-

International Classification:H01R 4304

-

US Classification:29753

-

Abstract:An automatic terminal applicator in which stripped wire ends are automatically guided and inserted into the insulation and wire barrel portions of terminals attached to a moving belt is disclosed. The belt is indexed through the crimping station between the upper and lower insulation and wire crimping dies of the press. A split funnel guide includes a spring-loaded portion and a complementary stationary portion respectively fastened with the upper and lower crimping dies. When the dies are closed, an aperture is formed at the apex of the funnel immediately adjacent the insulation portion of the leading terminal and whose cross-sectional area is no greater than the corresponding area of the insulation portion of the terminal. The wire is positioned transversely of the terminal and coaxial therewith. Thereafter, the wire is inserted into the funnel and guided thereby into the barrel of the terminal.

-

Terminal Applicator Apparatus For Terminals In Strip Form

view source -

US Patent:40430324, Aug 23, 1977

-

Filed:May 12, 1976

-

Appl. No.:5/685794

-

Inventors:Paul Joseph Spangler - Novelty OH

-

Assignee:International Telephone and Telegraph Corporation - New York NY

-

International Classification:H01R 4304

B21F 1500 -

US Classification:29628

-

Abstract:A terminal applicator for applying terminals in the form of a continuous belt and having a crimping die and a crimping anvil movable relatively towards and away from each other is disclosed. The belt of terminals is fed along a feed path extending behind the dies to present and index the leading terminal on the belt to the dies. After crimping, the dies move relatively away from each other to free the crimped terminal. An ejector means is spaced laterally of the feed path and moves into engagement with the wire and away from the dies, while the other end of the wire is held by a wire clamp, so that the crimped terminal is broken away from, and thereby removed from, the belt. In one embodiment, the wire clamp is movably mounted for lateral movement toward and away from the dies, so that the wire end may be inserted into a closed-barrel terminal prior to the crimping operation.

Classmates

Paul Spangler

view sourceSchools:

Walkersville High School Walkersville MD 1982-1986

Community:

Laurie Christy, Cassandra Wagner, Ronnie West

Paul Spangler

view sourceSchools:

Hill Murray School Maplewood MN 1975-1979

Community:

Joe Finger, Paul Johnson

Paul Spangler, Bearden Hi...

view source

Bearden High School, Knox...

view sourceGraduates:

Paul Spangler (1950-1954),

Michael Haimelin (1980-1984),

Katherine Beard (1984-1988),

Sybil Cox (1967-1971)

Michael Haimelin (1980-1984),

Katherine Beard (1984-1988),

Sybil Cox (1967-1971)

Youtube

Flickr

Myspace

Googleplus

Paul Spangler

Paul Spangler

Paul Spangler

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Paul Spangler

view source

Roger Paul Spangler

view sourceGet Report for Paul J Spangler from Medina, OH, age ~54