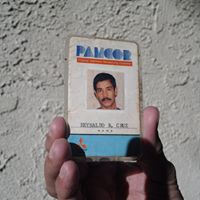

Reynaldo Gonzales Cruz

age ~69

from Bourbonnais, IL

- Also known as:

-

- Reynaldo G Cruz

- Revnaldo G Cruz

- Johna Cruz

- Reynaldo Gonzalescruz

- Phone and address:

-

201 Meadows Rd S, Bourbonnais, IL 60914

(815)9326956

Reynaldo Cruz Phones & Addresses

- 201 Meadows Rd S, Bourbonnais, IL 60914 • (815)9326956

- Bradley, IL

Us Patents

-

Selectively Hydrogenated High Oleic Oil Compositions And Process

view source -

US Patent:6391369, May 21, 2002

-

Filed:Mar 27, 1996

-

Appl. No.:08/622953

-

Inventors:Frank R. Kincs - Bradley IL

Reynaldo G. Cruz - Bourbonnais IL

Robert K. Johnson - Bourbonnais IL -

Assignee:Bunge Foods Corporation - Bradley IL

-

International Classification:A23D 900

-

US Classification:426607, 426 99, 514141

-

Abstract:Butters are made from high oleic vegetable oils during a procedure by which a large percentage of the oleic acid is transformed into trans-configured elaidic acid, without significantly increasing the saturated fat present in the high oleic vegetable oil. The vegetable oils have an initial oleic acid content of at least about 75 weight percent, with the hard butter made from it being a high elaidic hard fat having at least about 65% trans-configured elaidic acid. The preferred process is a single-step procedure of hydrogenation in the presence of a deadened catalyst such as a sulfur-poisoned nickel catalyst.

-

Pelletized Shortening

view source -

US Patent:60541679, Apr 25, 2000

-

Filed:Jan 19, 1999

-

Appl. No.:9/234279

-

Inventors:Frank R. Kincs - Chicago IL

Reynaldo G. Cruz - Bourbonnais IL

Thomas G. Crosby - Bourbonnais IL -

Assignee:Bunge Foods Corporation - Bradley IL

-

International Classification:A21D 1000

-

US Classification:426549

-

Abstract:A pelletized shortening is prepared by a process which includes melting, cooling, solidifying and extruding natural and/or synthetic shortening materials to provide shortening pellets or chunks which, without requiring further processing, resist clumping together at at least moderate temperatures of about 70. degree. F. (about 21. degree. C. ). The pelletized shortening has a hardness or solids profile which is especially suitable for baking applications and imparts a tenderizing effect in bakery type products while still providing a shortening in a form that is easy to handle inasmuch as it is pourable or able to be metered in a flowing particulate style. While it has relatively high solids at room temperature or storage conditions, the solids content of the pelletized shortening dissipates rapidly enough such that the solids reduction will provide the desired tenderizing effect in dough products including biscuits and pizza crusts.

-

Baking Formulation Containing Pelletized Shortening

view source -

US Patent:58661875, Feb 2, 1999

-

Filed:Aug 28, 1996

-

Appl. No.:8/704117

-

Inventors:Frank R. Kincs - Bradley IL

Reynaldo G. Cruz - Bourbonnais IL -

Assignee:Bunge Foods Corporation - Bradley IL

-

International Classification:A21D 1000

-

US Classification:426549

-

Abstract:A pelletized shortening is prepared by a process which includes melting, cooling, solidifying and extruding vegetable oil to provide shortening pellets or chunks which, without requiring further processing, resist clumping together at at least moderate temperatures of about 70. degree. F. (about 21. degree. C. ). The pelletized shortening has a hardness or solid fat profile which is especially suitable for baking applications and imparts a tenderizing effect in bakery type products while still providing a shortening in a form that is easy to handle inasmuch as it is pourable or able to be metered in a flowing particulate style. While it has relatively high solids at room temperature or storage conditions, the solids content of the pelletized shortening dissipates rapidly enough such that the solids reduction will provide the desired tenderizing effect in dough products including biscuits and pizza crusts.

Resumes

Driver

view sourceIndustry:

Hospital & Health Care

Work:

American Red Cross

Driver

Islandwide Express Jan 2003 - Nov 2009

Supervisor

Driver

Islandwide Express Jan 2003 - Nov 2009

Supervisor

Education:

Escuela Superior Vocacional Miguel Such 1989 - 1992

Reynaldo Cruz

view source

Reynaldo Dela Cruz

view source

Reynaldo Cruz

view source

Reynaldo Cruz

view source

Reynaldo De La Cruz

view source

Supervisor

view sourceWork:

Fbinc

Supervisor

Supervisor

Reynaldo Cruz

view sourceLocation:

United States

Flickr

Reynaldo Kapitan Cruz

view source

Reynaldo Cruz Jr.

view source

Reynaldo Dela Cruz Jr.

view source

Reynaldo Montreal Cruz

view source

Reynaldo Cruz Castillo

view source

Reynaldo Cruz

view source

Reynaldo Cruz III

view source

Reynaldo Cruz

view sourceClassmates

Reynaldo Cruz

view sourceSchools:

Hollywood High School of Arts Los Angeles CA 2000-2004

Community:

Michael Reynolds, Lucy Hernandez, Rick Ramirez, Norma Rizo, Michelle Jeffries, Amanda Buck

Reynaldo Cruz

view sourceSchools:

Colegio La Merced High School Cayey NJ 1986-1989

Community:

Linnette Ortiz, Luis Gonzalez, Grisel Grisel, Jorge Delgado

Reynaldo Dela Cruz

view sourceSchools:

V. Mapa High School Manila OR 1964-1968

Community:

Danilo Bernaldez

Reynaldo Cruz

view sourceSchools:

Teddy Bear Nursery School Newton NH 1993-1997

Community:

Cammie Melius, Marisa Dibiaso, Gabriel Alice, Fionna Schinkel, Johan Johan

Immokalee Middle School, ...

view sourceGraduates:

Reynaldo Cruz (1976-1977),

Reynaldo Cruz (1975-1976),

Patricia Charles (1997-2000),

Anna Massiate (1993-1997)

Reynaldo Cruz (1975-1976),

Patricia Charles (1997-2000),

Anna Massiate (1993-1997)

Colegio La Merced High Sc...

view sourceGraduates:

Reynaldo Cruz (1986-1989),

Celimar De Jesus (1992-1996)

Celimar De Jesus (1992-1996)

University of Puerto Rico...

view sourceGraduates:

Reynaldo Cruz (1989-1994),

Ruth Solivan (1995-1998),

Joe Jordan (1993-2005),

Julio Eric (1979-1984)

Ruth Solivan (1995-1998),

Joe Jordan (1993-2005),

Julio Eric (1979-1984)

Plaxo

Reynaldo Cruz

view sourceElectronic Tech. at Creation Technologies Inc.

Youtube

Googleplus

Reynaldo Cruz

About:

Cray Cray

Bragging Rights:

I am King ^.^

Reynaldo Cruz

Reynaldo Cruz

Reynaldo Cruz

Reynaldo Cruz

Reynaldo Cruz

Reynaldo Cruz

Reynaldo Cruz

Myspace

Reynaldo Cruz

view sourceLocality:

Mount Vernon its all about that 360(_), Texas

Gender:

Male

Birthday:

1950

Get Report for Reynaldo Gonzales Cruz from Bourbonnais, IL, age ~69