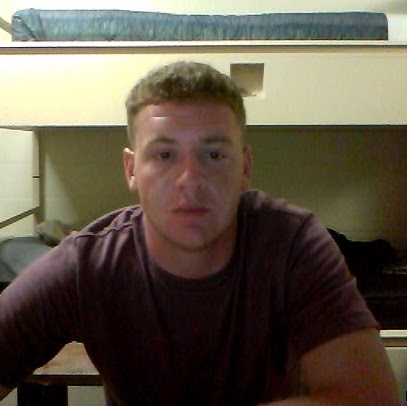

Richard P Eddy

age ~56

from Greer, SC

- Also known as:

-

- Richard Patrick Eddy

- Rick P Eddy

- Dick P Eddy

- Richard Peddy

- Richard Eddie

Richard Eddy Phones & Addresses

- Greer, SC

- Greenville, SC

- 2032 Playa Rd, Carlsbad, CA 92009 • (949)6321549

- 58 Cayman Brac, Aliso Viejo, CA 92656

- Playa del Rey, CA

- Manhattan Beach, CA

- Redondo Beach, CA

- Burbank, CA

- Hermosa Beach, CA

- 2032 Playa Rd, Carlsbad, CA 92009

Medicine Doctors

Richard L. Eddy

view sourceSpecialties:

Endocrinology, Diabetes & Metabolism

Work:

Institute Of Diabetes & Endocrinology

221 W Stewart Ave STE 101, Medford, OR 97501

(541)7762003 (phone), (541)7769833 (fax)

221 W Stewart Ave STE 101, Medford, OR 97501

(541)7762003 (phone), (541)7769833 (fax)

Education:

Medical School

Thomas Jefferson University, Jefferson Medical College

Graduated: 1961

Thomas Jefferson University, Jefferson Medical College

Graduated: 1961

Conditions:

Diabetes Mellitus (DM)

Disorders of Lipoid Metabolism

Hyperthyroidism

Hypothyroidism

Metabolic Syndrome

Disorders of Lipoid Metabolism

Hyperthyroidism

Hypothyroidism

Metabolic Syndrome

Languages:

English

Description:

Dr. Eddy graduated from the Thomas Jefferson University, Jefferson Medical College in 1961. He works in Medford, OR and specializes in Endocrinology, Diabetes & Metabolism. Dr. Eddy is affiliated with Asante Rogue Regional Medical Center.

Us Patents

-

Endless Loop Transport And Storage System

view source -

US Patent:4749138, Jun 7, 1988

-

Filed:Dec 1, 1986

-

Appl. No.:6/936399

-

Inventors:Richard P. Eddy - Gardena CA

-

Assignee:Christie Electric Corp. - Torrance CA

-

International Classification:B65H 1748

-

US Classification:242 5519R

-

Abstract:An apparatus and method for continuously storing a strip of material in a coil, such as a multi-hour motion picture theatre film. The apparatus includes a flat platter with drive means for rotating the platter, a cam mounted for rotation with the platter and having a cam track with alternating sections of greater distance and lesser distance from the center of the platter, and means for applying the incoming strip to the periphery of the coil on the platter. The applying means includes a cam follower for engaging the cam track to position the strip in a coil on the platter having inwardly directed rounded cusps with arcuate outer peripheries therebetween. In order to produce or eliminate tension in the strip, a fixed roller is positioned at the arcuate outer periphery for urging the coil inward as the roller contacts the arcuate periphery. Further improvements include provision of a friction surface on the platter for enhancing cusp formation, and a takeoff roller assembly positioned above the platter for improved strip takeoff operation.

-

Film Tensioning Device

view source -

US Patent:41449916, Mar 20, 1979

-

Filed:Oct 11, 1977

-

Appl. No.:5/840815

-

Inventors:Richard P. Eddy - Gardena CA

-

Assignee:Christie Electric Corp. - Los Angeles CA

-

International Classification:B65H 2308

-

US Classification:226195

-

Abstract:A film tensioning device for maintaining tension in the film in a film transport system such as a motion picture projector. A tension roller mounted between pressure rollers with the film running over the tension roller, with a spring urging the pressure rollers against the film to prevent slippage of the film on the tension roller. A curved spring carried within the tension roller and engageable with a stop providing sliding friction with the tension roller. The spring is readily removable for substitution of a different spring to provide a different magnitude of tension in the device.

-

Surface Deviation Compensation For A Beam Scanning System

view source -

US Patent:45859388, Apr 29, 1986

-

Filed:Jan 23, 1984

-

Appl. No.:6/573297

-

Inventors:Don B. Neumann - Laguna Beach CA

Richard P. Eddy - Gardena CA -

Assignee:Excellon Industries - CA

-

International Classification:H01J 314

-

US Classification:250235

-

Abstract:The image formed by a laser flying spot scanner on a photosensitive medium is subject to error in size and/or position because of deviation of the photosensitive surface from a nominal position. The deviation will occur if the substrate carrying the photosensitive surface does not have a uniform thickness. In a scanning system having a code mask that produces reference signals for controlling timing of writing beam modulation, compensation for the error is provided by maintaining a fixed distance between the code mask and the surface of the medium. The code mask floats freely upon the medium surface to move up and down with height variations of the surface as the medium passes under the code member and under the writing beam. Alternatively, the platen that supports the photosensitive medium is allowed to float and is continuously urged upwardly against spacing or position sensing devices to maintain the medium surface at a fixed distance from the mask.

-

Endless Loop Transport And Storage System

view source -

US Patent:48364630, Jun 6, 1989

-

Filed:Jul 1, 1987

-

Appl. No.:7/068325

-

Inventors:Richard P. Eddy - Gardena CA

-

Assignee:Christie Electric Corporation - Torrance CA

-

International Classification:B65H 1748

-

US Classification:242 5519R

-

Abstract:An apparatus and method for continuously storing a strip of material in a coil, such as a multi-hour motion picture theatre film. The apparatus includes a flat platter with drive means for rotating the platter, a cam mounted for rotation with the platter and having a cam track with alternating sections of greater distance and lesser distance from the center of the platter, and means for applying the incoming strip to the periphery of the coil on the platter. The applying means includes a cam follower for engaging the cam track to position the strip in a coil on the platter having inwardly directed rounded cusps with arcuate outer peripheries therebetween. In order to reduce or eliminate tension in the strip, a roller is positioned at the outer periphery for urging the coil inward as the roller contacts the coil. Further improvements include provision of a high friction surface on the platter for enhancing arc formation and a low friction surface for enhancing cusp formation, and a takeoff roller assembly positioned above the platter for improved strip takeoff operation.

-

Axial Flow Continuous Loop Film Storage Spool Apparatus

view source -

US Patent:42470587, Jan 27, 1981

-

Filed:Jan 19, 1979

-

Appl. No.:6/004802

-

Inventors:Richard P. Eddy - Gardena CA

-

International Classification:G03B 2100

G11B 2308

G11B 2312 -

US Classification:242 5517

-

Abstract:This invention provides for the edgewise storage of a filmstrip in the cavity between two concentric drums. The filmstrip is wound into the cavity between the two drums by a feed roller and pressure rollers as the drums rotate synchronously. The feed roller, in conjunction with the pressure rollers, serve to advance the filmstrip through the cavity, thereby providing storage for a considerable length of film. Since the film is pushed through the cavity to the opposite end, and made available there for use, the invention is especially appropriate for applications requiring endless loop filmstrips. The cavity formed by the drums may be of constant diameter (if the drums are cylindrical), arcuate, tapered, etc. , depending upon the shapes of the corresponding surfaces of the concentric drums.

-

Stabilization Systems For Vibration Isolators

view source -

US Patent:53799801, Jan 10, 1995

-

Filed:Nov 27, 1992

-

Appl. No.:7/982504

-

Inventors:Worthington B. Houghton - Newport Beach CA

Richard P. Eddy - Gardena CA

Jay R. McCoy - San Juan Capistrano CA -

Assignee:Newport Corporation - Irvine CA

-

International Classification:F16M 1300

-

US Classification:248550

-

Abstract:Intermittent stabilization of a load table supported by pneumatic vibration isolators is provided by determining a load shift condition, increasing passage of gas to the pneumatic vibration isolators and imposing external or internal damping on the load table in response to that load shift condition. For internal damping, the pneumatic vibration isolator is provided with damping fluid in one of its pneumatic chambers and a damping fluid friction passage is provided between that damping fluid in that one pneumatic chamber and the other pneumatic chamber.

-

Endless Loop Transport And Storage System

view source -

US Patent:49039067, Feb 27, 1990

-

Filed:Jul 13, 1989

-

Appl. No.:7/380726

-

Inventors:Richard P. Eddy - Gardena CA

-

Assignee:Christie Electric Corp. - Torrance CA

-

International Classification:B65H 2026

-

US Classification:242 5519R

-

Abstract:An apparatus for continuously storing a strip of material in a coil, including a flat platter and a drive for rotating the platter, the coil lying edgewise on the platter and the strip including an incoming strip portion leading to the coil periphery and an outgoing strip portion leading from the coil center, an arrangement for applying the incoming strip portion to the periphery of the coil of the strip on the platter as it rotates, in an even number of substantially straight strip sections joined at curved corners providing alternating even and odd strip sections and applying an inward pressure to the even strip sections to form the even strip sections into concave strip sections. A resistance pad positioned on the platter at the odd strip sections for engaging the strip edge and resisting movement of the strip toward the coil center, with the resistance pad having a friction producing surface with a lower level and a higher level with an inclined surface between the levels and with the outer edge of the higher level being substantially straight, and a skid pad positioned on the platter at the even strip sections for engaging the strip edge and enhancing movement of the strip toward the coil center, with the skid pad having a convex inner edge with an upward turned lip.

-

Endless Loop Transport And Storage System

view source -

US Patent:47491388, Jun 7, 1988

-

Filed:Dec 1, 1986

-

Appl. No.:6/936399

-

Inventors:Richard P. Eddy - Gardena CA

-

Assignee:Christie Electric Corp. - Torrance CA

-

International Classification:B65H 1748

-

US Classification:242 5519R

-

Abstract:An apparatus and method for continuously storing a strip of material in a coil, such as a multi-hour motion picture theatre film. The apparatus includes a flat platter with drive means for rotating the platter, a cam mounted for rotation with the platter and having a cam track with alternating sections of greater distance and lesser distance from the center of the platter, and means for applying the incoming strip to the periphery of the coil on the platter. The applying means includes a cam follower for engaging the cam track to position the strip in a coil on the platter having inwardly directed rounded cusps with arcuate outer peripheries therebetween. In order to produce or eliminate tension in the strip, a fixed roller is positioned at the arcuate outer periphery for urging the coil inward as the roller contacts the arcuate periphery. Further improvements include provision of a friction surface on the platter for enhancing cusp formation, and a takeoff roller assembly positioned above the platter for improved strip takeoff operation.

Name / Title

Company / Classification

Phones & Addresses

Manager

Usmx Services Group, LC

1805 N Carson St, Carson City, NV 89701

2353 Irvine Ave, Newport Beach, CA 92660

1806 N Carson St, Carson City, NV 89701

2353 Irvine Ave, Newport Beach, CA 92660

1806 N Carson St, Carson City, NV 89701

General Partner

Fine Brook Village

Apartment Building Operator

Apartment Building Operator

1555 Mesa Verde Dr E, Costa Mesa, CA 92626

(714)5408871

(714)5408871

Tpl Properties, Ltd

2353 Irvine Ave, Newport Beach, CA 92660

2100 E 14 Ave, Denver, CO 80206

2100 E 14 Ave, Denver, CO 80206

General Partner, Partner

Beauchamp & Warmington Co, LLC

Apartment Building Operator

Apartment Building Operator

1555 Mesa Verde Dr E, Costa Mesa, CA 92626

(714)9795290

(714)9795290

President

PARK & GO, INC

Automobile Parking

Automobile Parking

3125 Pacific Hwy, San Diego, CA 92101

5160 Campus Dr, Newport Beach, CA 92660

2535 Pacific Hwy, San Diego, CA 92101

(619)5259885

5160 Campus Dr, Newport Beach, CA 92660

2535 Pacific Hwy, San Diego, CA 92101

(619)5259885

President

Grand Junction Investors, Inc

PO Box 18798, Irvine, CA 92623

President

INVOLUTE MANUFACTURING CORPORATION

13472 5 St #14, Chino, CA 91710

President

EDDY N/C FAB, INC

Mfg Plastic Products

Mfg Plastic Products

1241 N Barsten Way, Anaheim, CA 92806

License Records

Richard Algernon Eddy

License #:

23144 - Active

Issued Date:

Jun 25, 2004

Renew Date:

Dec 1, 2015

Expiration Date:

Nov 30, 2017

Type:

Certified Public Accountant

Richard J Eddy

License #:

8686 - Expired

Category:

Electricians

Issued Date:

Jan 20, 2000

Expiration Date:

Dec 31, 2000

Type:

Electrician Apprentice

Richard W Eddy

License #:

060353 - Expired

Category:

Real Estate

Type:

Salesperson

Resumes

Richard Eddy

view sourceLocation:

United States

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view sourceLocation:

United States

Googleplus

Richard Eddy

Lived:

La Verne, CA

Lakewood, CA

Lakewood, CA

Work:

Cona Financial Group - Financial Advisor (2010)

Transamerica Financial Advisors - Financial Advisor (2008-2010)

Self-Employed - Entrepreneur (1984-2008)

Transamerica Financial Advisors - Financial Advisor (2008-2010)

Self-Employed - Entrepreneur (1984-2008)

Education:

The American College - ChFC Program, Azusa Pacific University - Human Development, Cal State Fullerton - American Studies, Chino High School

Relationship:

Married

About:

Born and raised in Southern California, I am a lifelong entrepreneur. I currently run an independent financial planning and investment advisory practice, Cona Financial Group. When I am not working, y...

Tagline:

Financial Planner | Investment Advisor | Entrepreneur | Occasional Pot Stirrer

Bragging Rights:

Invented ToSSMAX, a revolutionary approach to maximizing your retirement income.

Richard Eddy

Lived:

Tigard OR

Lake Forest CA

Lake Forest CA

Work:

Huron Consulting Group - Healthcare Consultant (2012)

KPMG - IT Auditor (2010-2012)

Screen Scraper - Java Programmer (2010)

KPMG - IT Auditor (2010-2012)

Screen Scraper - Java Programmer (2010)

Education:

Brigham Young University - Information Systems

Richard Eddy

Work:

United states of the fu**en America

Education:

Washtenaw Community College - Automotive mechanics

About:

Thug for life

Bragging Rights:

I am the best marine ever.

Richard Eddy

Richard Eddy

Richard Eddy

Richard Eddy

Richard Eddy

Myspace

Richard Dickson Eddy

view source

Richard James Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy

view source

Richard Eddy Mz Roca

view sourceClassmates

Richard (Eddy) Young

view sourceSchools:

Alexandria High School Alexandria LA 1980-1984

Community:

Ralph Gauthier, Vanessa Haakenson

Richard Eddy

view sourceSchools:

Douglas MacArthur Elementary School Lakewood CA 1976-1977, Mark Twain Elementary School Long Beach CA 1977-1978, Magnolia Junior High School Chino CA 1979-1980

Community:

Teresa Hollingshead, Elaine Sargent, Gina Mcdade

Richard Eddy

view sourceSchools:

St. Francis Xavier Seminary High School Duxbury MA 1949-1953

Community:

Donald Breidt, Donald White, John Finnerty, Charles Armstrong, Maurice Donovan, Francis Brown

Richard Eddy

view sourceSchools:

Dos Palos High School Dos Palos CA 1972-1976

Community:

Robert Bob, Barbara Hennagan, Beverly Devers

Richard Eddy

view sourceSchools:

Center Elementary School Cedar Grove NJ 1951-1958, South Junior High School Bloomfield NJ 1958-1961

Community:

Susan Kelly, Diane Bothem, Bernie Angelo, Robert Migliara

Richard Eddy

view sourceSchools:

Clay - Battelle High School Blacksville WV 1993-1997

Community:

Tim Flack

Richard Eddy

view sourceSchools:

Gault Elementary School Santa Cruz CA 1945-1952, Branciforte Junior High School Santa Cruz CA 1952-1955

Community:

Janet Heine, Ashley Niemi

Richard Eddy

view sourceSchools:

Merrifield Public School Sault Ste. Marie Morocco 1954-1958

Community:

Sandra Stiber, Linda Schmuul, Martin Lewis, Ronald Monette, Sally Ritchie, Lilly Fera

Youtube

Flickr

Plaxo

Richard Eddy

view sourceLa Verne, CAConsultant at Richard Eddy Business Financial Stra... Past: President at Involute Manufacturing Corp. I am a financial professional and business consultant working with some of the most successful members of my community. I advise my clients on a variety of... I am a financial professional and business consultant working with some of the most successful members of my community. I advise my clients on a variety of issues including insurance, retirement planning and family wealth management, helping them to design and implement strategies that allow them...

Eddy Richard CHANLATTE

view sourcePort-au-Prince

Get Report for Richard P Eddy from Greer, SC, age ~56