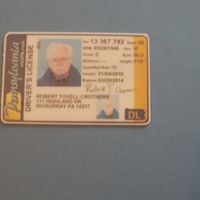

Robert A Crothers

age ~75

from Noblesville, IN

- Also known as:

-

- Robert S Crothers

- Bob A Crothers

- Rob A Crothers

- Ra Crothers

- Crothers A Robert

Robert Crothers Phones & Addresses

- Noblesville, IN

- Plymouth, MI

- Kokomo, IN

- Palm Harbor, FL

- Canton, MI

Us Patents

-

Method And Apparatus For Automatic Titration Of Solder Flux

view source -

US Patent:56399545, Jun 17, 1997

-

Filed:Nov 13, 1995

-

Appl. No.:8/558123

-

Inventors:Robert Arnold Crothers - Noblesville IN

Robert Francis Krakora - Kokomo IN

Robert George Starke - Greentown IN

Michael Lee Paul - Zionsville IN -

Assignee:Delco Electronics Corporation - Kokomo IN

-

International Classification:B23K 300

-

US Classification:73 101

-

Abstract:An automatic titration system that periodically and automatically determines the pH level and acid number of a flux solution in a flux reservoir associated with an automatic flux application apparatus. The automatic titration system pulls the flux solution from the flux reservoir of the fluxing machine on a continuous basis to be filtered. Flux to be sampled by the automatic titration system is deposited in a titration chamber where a titration analysis is performed. A known reagent solution is mixed with the flux solution in the titration chamber to determine the pH level and acid number of the sampled flux during the titration operation. Containers of flux solution and thinner solution located in the automatic titration system allow flux and thinner to be dispensed into the flux reservoir depending on the outcome of the titration analysis, so as to maintain the flux in the flux reservoir at the desirable pH level and acid number.

-

Directional Flow Control Device For A Wave Soldering Apparatus

view source -

US Patent:57948372, Aug 18, 1998

-

Filed:Nov 25, 1996

-

Appl. No.:8/756128

-

Inventors:Steven William Cottingham - Kokomo IN

Frank Clyde Spaulding - Sharpsville IN

Maxwell Geoffrey Davies - Noblesville IN

Stanley James Pugh - Kokomo IN

Robert Arnold Crothers - Noblesville IN -

Assignee:Delco Electronics Corporation - Kokomo IN

-

International Classification:B23K 306

-

US Classification:228 37

-

Abstract:A flow control device for a solder wave apparatus that includes an outlet or nozzle from which molten solder flows in an upward direction to contact the lower surface of a target, such as a circuit board. The flow control device provides a screen and baffle that control the flow pattern of molten solder to the nozzle so as to result in a near-parallel solder wave above the nozzle. The screen includes a pair of spaced-apart parallel panels that are disposed upstream of the nozzle. Each of the panels has apertures through which the molten solder flows before entering the nozzle. The apertures of the panels are offset from each other, such that none of the apertures are coaxial but instead overlap each other when superimposed. The baffle is disposed further upstream of the screen, and includes a number of fins disposed substantially perpendicular to the panels. The fins are arranged such that their lengths become progressively shorter in a direction away from the center of the baffle.

Name / Title

Company / Classification

Phones & Addresses

President,Treasurer,Chairman

RCLC, INC

Principal

Cornerstone Communications

Communication Services

Communication Services

20531 Country Lk Blvd, Noblesville, IN 46062

Resumes

Robert Crothers

view source

Robert Crothers

view sourceLocation:

United States

Robert Crothers Noblesville, IN

view sourceWork:

Fortis College

Aug 2010 to 2000

HVACR Program Director Park Emerson Ste K

Indianapolis, IN

Feb 2010 to Jan 2013

Mid-West HVAC Repair and Service Technician One Hour Heating & Cooling

Feb 2008 to Feb 2010

Preventive Maintenance Technician Residential services Crothers Mechanical Services

Noblesville, IN

Feb 2003 to Mar 2008

HVAC/R Repair Technician US Air Force Reserves-Retired

Wright-Patterson AFB, OH

Aug 1976 to May 2005

Aircraft Maintenance Technician-Flight Line Technical Trainer/Supervisor

Aug 2010 to 2000

HVACR Program Director Park Emerson Ste K

Indianapolis, IN

Feb 2010 to Jan 2013

Mid-West HVAC Repair and Service Technician One Hour Heating & Cooling

Feb 2008 to Feb 2010

Preventive Maintenance Technician Residential services Crothers Mechanical Services

Noblesville, IN

Feb 2003 to Mar 2008

HVAC/R Repair Technician US Air Force Reserves-Retired

Wright-Patterson AFB, OH

Aug 1976 to May 2005

Aircraft Maintenance Technician-Flight Line Technical Trainer/Supervisor

Education:

Indiana Institute of Technology

Indianapolis, IN

2000

BSBA in Management Community College of the Air Force

, AL

2000

AAS in Aircraft Maintenance System Technology

Indianapolis, IN

2000

BSBA in Management Community College of the Air Force

, AL

2000

AAS in Aircraft Maintenance System Technology

Skills:

Word, Excell, Visio, CampusVue, Campus POrtal, Jupiter, Engrade, and many other software programs

Cto/Chief Architect At Cornerstone Communications And Owner, Cornerstone Communications

view sourceLocation:

Indianapolis, Indiana Area

Industry:

Computer Software

Youtube

Flickr

Googleplus

Robert Crothers

Robert Crothers

Robert Crothers

Myspace

Robert Crothers

view source

Robert Crothers

view source

Robert Crothers

view source

Robert Crothers

view source

Robert Crothers

view source

Robert Crothers

view source

Robert Crothers

view source

Robert Crothers

view sourceClassmates

Robert Crothers

view sourceSchools:

Courtland High School Fredericksburg VA 1997-2001

Community:

Gina Vandenberg, Danielle Dunning

Robert Crothers

view sourceSchools:

Powder Mill Elementary School Beltsville MD 1969-1976, Martin Luther King Jr. Junior High School Beltsville MD 1976-1977

Robert Crothers

view sourceSchools:

Verona High School Verona PA 1956-1960

Community:

Amy Hamilton, Nick Caruso, Garry Lyle, Charles Craig, Linda Cartwright, Robyn Nolan

Robert Crothers

view sourceSchools:

Turtle Creek High School Turtle Creek PA 1949-1953

Community:

Francis Bennati

Robert Crothers

view sourceSchools:

Cleveland Elementary School Stockton CA 1960-1966, Stockton Junior High School Stockton CA 1966-1969

Community:

Joe Colby

Robert Crothers

view sourceSchools:

Mascoutah High School Mascoutah IL 2001-2005

Community:

Josiah Foushee, Audessa Watkins, Christian Harding, Samantha Pendegraft, Patricia Kallbreier, Amber Novak, Ryan Kruse, Ashley Pope, Stephanie Seibold, Allyson Stelfox, Christopher Evans

Robert Crothers | Tyler C...

view source

Cleveland Elementary Scho...

view sourceGraduates:

Robert Crothers (1960-1966),

Justin Ogren (1988-1993),

Steve Scott (1966-1968),

Irv Handel (1971-1976),

Angela Christine Marquez (1978-1982)

Justin Ogren (1988-1993),

Steve Scott (1966-1968),

Irv Handel (1971-1976),

Angela Christine Marquez (1978-1982)

Get Report for Robert A Crothers from Noblesville, IN, age ~75