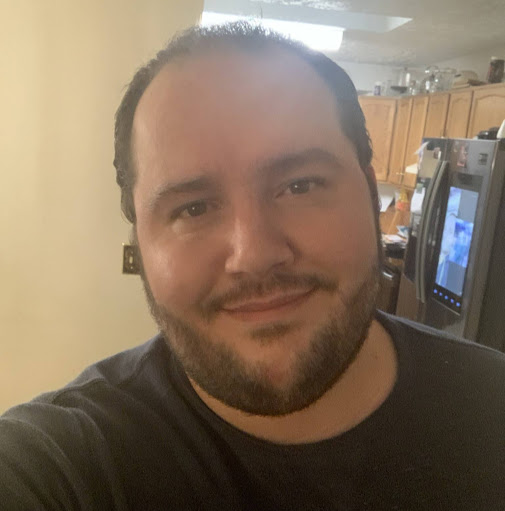

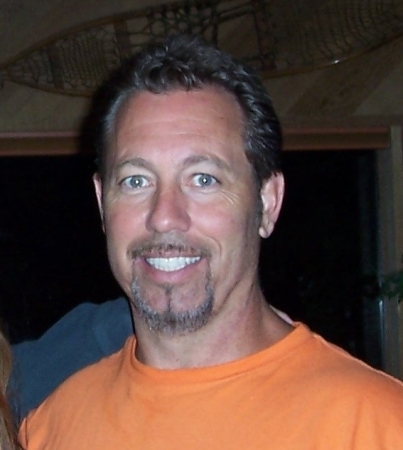

Robert G Link

age ~56

from Marietta, GA

- Also known as:

-

- Robert A Link

- Rob G Link

- Link G Robert

- Phone and address:

- 1880 Ardsley Dr, Marietta, GA 30062

Robert Link Phones & Addresses

- 1880 Ardsley Dr, Marietta, GA 30062

- Atlanta, GA

- 94 Village Ln, Rochester, NY 14610

- Falls Church, VA

- Brooklyn, NY

- Kent, OH

- Fairport, NY

- Arlington, VA

Work

-

Company:BELLEVUE HOSPITAL CENTER

-

Address:462 1St Ave, New York, NY 10016

-

Phones:(212)5625555

Education

-

School / High School:Washington Center / School of Medicine1983

Languages

English

Awards

Healthgrades Honor Roll

Ranks

-

Certificate:Internal Medicine, 1986

Specialities

Internal Medicine

Medicine Doctors

Dr. Robert N Link, New York NY - MD (Doctor of Medicine)

view sourceSpecialties:

Internal Medicine

Address:

BELLEVUE HOSPITAL CENTER

462 1St Ave, New York, NY 10016

(212)5625555 (Phone)

Bellevue Hosp Ctr Intrnl Medcn

462 1St Ave Suite Mn30, New York, NY 10016

(212)5624141 (Phone)

462 1St Ave, New York, NY 10016

(212)5625555 (Phone)

Bellevue Hosp Ctr Intrnl Medcn

462 1St Ave Suite Mn30, New York, NY 10016

(212)5624141 (Phone)

Certifications:

Internal Medicine, 1986

Awards:

Healthgrades Honor Roll

Languages:

English

Education:

Medical School

Washington Center / School of Medicine

Graduated: 1983

Washington Center / School of Medicine

Graduated: 1983

Robert J. Link

view sourceSpecialties:

Anesthesiology

Work:

Heartland Anesthesia Consultants

913 N Dixie Ave, Elizabethtown, KY 42701

(270)7374600 (phone), (270)7371722 (fax)

913 N Dixie Ave, Elizabethtown, KY 42701

(270)7374600 (phone), (270)7371722 (fax)

Education:

Medical School

University of Louisville School of Medicine

Graduated: 1989

University of Louisville School of Medicine

Graduated: 1989

Languages:

English

Description:

Dr. Link graduated from the University of Louisville School of Medicine in 1989. He works in Elizabethtown, KY and specializes in Anesthesiology. Dr. Link is affiliated with Hardin Memorial Hospital.

Robert B. Link

view sourceSpecialties:

Emergency Medicine

Work:

Ochsner ClinicOchsner Medical Center

1514 Jefferson Hwy, New Orleans, LA 70121

(504)8423930 (phone)

1514 Jefferson Hwy, New Orleans, LA 70121

(504)8423930 (phone)

Education:

Medical School

Tulane University School of Medicine

Graduated: 1983

Tulane University School of Medicine

Graduated: 1983

Languages:

Chinese

English

French

Spanish

English

French

Spanish

Description:

Dr. Link graduated from the Tulane University School of Medicine in 1983. He works in New Orleans, LA and specializes in Emergency Medicine. Dr. Link is affiliated with Ochsner Medical Center Jefferson Highway.

Robert E. Link

view sourceSpecialties:

General Practice

Work:

Seneca Nation Health System

987 R C Hoag Dr, Salamanca, NY 14779

(716)9455894 (phone), (716)9450308 (fax)

987 R C Hoag Dr, Salamanca, NY 14779

(716)9455894 (phone), (716)9450308 (fax)

Languages:

English

Description:

Mr. Link works in Salamanca, NY and specializes in General Practice. Mr. Link is affiliated with Olean General Hospital.

Robert Link, New York NY

Work:

Bellevue Hospital Center

462 1St Ave, New York, NY 10016

462 1St Ave, New York, NY 10016

Us Patents

-

Process For Formation And Collection Of Particles Using Cryogenic Material

view source -

US Patent:7931834, Apr 26, 2011

-

Filed:Feb 13, 2007

-

Appl. No.:11/674291

-

Inventors:Rajesh V. Mehta - Rochester NY, US

Robert Link - Webster NY, US

Michael A. Marcus - Honeoye Falls NY, US -

Assignee:Eastman Kodak Company - Rochester NY

-

International Classification:B29B 9/00

B22F 9/00

B22F 9/02

B22F 9/06 -

US Classification:264 5, 75331, 427457

-

Abstract:A process for the formation of particles of a target material is disclosed, comprising: (i) introducing the target material into a particle formation vessel, and forming a continuous liquid surface of the target material in the particle formation vessel, and an interface between said liquid surface of the target material and additional gaseous contents of said particle formation vessel; (ii) introducing a stream of cryogenic material including solid particles of cryogenic material into the particle formation vessel and into contact with the target material in a liquid state below the continuous liquid surface; (iii) allowing rapid volumetric expansion of the cryogenic material into a gaseous state while in contact with the target material in a liquid state, and release of the expanded gaseous cryogenic material through the continuous liquid surface, and forming liquid droplet particles of the target material; and (iv) collecting the formed particles of the target material.

-

Phase Shifts For Two Groups Of Nozzles

view source -

US Patent:8104878, Jan 31, 2012

-

Filed:Nov 6, 2009

-

Appl. No.:12/613712

-

Inventors:Kim W. Montz - Webster NY, US

Todd R. Griffin - Webster NY, US

David L. Jeanmaire - Brockport NY, US

Robert Link - Webster NY, US -

Assignee:Eastman Kodak Company - Rochester NJ

-

International Classification:B41J 2/02

-

US Classification:347 75

-

Abstract:A method includes forming drops of first size by applying drop-forming pulses during unit time period, τ; forming drops of second size by applying drop-forming pulses during second size drop time period, τm, wherein the second sized drop time period is a multiple, m, of the unit time period, τm=m*τ, and m≧2; providing timing between drops for printing consecutive pixels is equal to τi=a*τwhere a is an integer ≧m and is a function of print media speed; forming the corresponding plurality of drop forming pulse sequences so as to form non-print drops and print drops according to the liquid pattern data; delaying the timing of the drop forming pulses sent to the transducers of the second group relative to the drop forming pulses sent to the transducers of the first group by a delay time τwhich is approximately equal to τ/2.

-

Method For Operating Continuous Printers

view source -

US Patent:8226216, Jul 24, 2012

-

Filed:Apr 1, 2010

-

Appl. No.:12/752576

-

Inventors:Robert Link - Webster NY, US

James L. Bello - Rochester NY, US

Todd R. Griffin - Webster NY, US -

Assignee:Eastman Kodak Company - Rochester NY

-

International Classification:B41J 2/02

-

US Classification:347 73, 347 74, 347 75, 347 80

-

Abstract:A method for operating a continuous inkjet printer, the method includes forming drops with a drop formation period being the time between consecutive drop formations; creating a portion of the drops that strike the print media for forming print drops; creating a portion of the created drops that do not strike the print media for forming catch drops; creating the print drops to print on a series of consecutive pixel locations; wherein a time between the creation of consecutive print drops is inconsistent which causes an additional catch drop so that a gap is created; wherein when a gap is created, adjusting a velocity of the print drop adjacent to the gap to cause the print drop to shift slightly toward the gap.

-

Dynamic Phase Shifts To Improve Stream Print

view source -

US Patent:8226217, Jul 24, 2012

-

Filed:Nov 6, 2009

-

Appl. No.:12/613683

-

Inventors:Kim W. Montz - Webster NY, US

Todd R. Griffin - Webster NY, US

David L. Jeanmaire - Brockport NY, US

Robert Link - Webster NY, US -

Assignee:Eastman Kodak Company - Rochester NY

-

International Classification:B41J 2/07

B41J 29/38

B41J 2/15

B41J 2/12 -

US Classification:347 74, 347 9, 347 11, 347 41, 347 78

-

Abstract:A method of forming print drops includes forming drops of a first size by applying drop forming energy pulses during a unit time period, τ; forming drops of a second size by applying drop forming energy pulses during a second drop time period, τ, wherein the second drop time period is a multiple, m, of the unit time period, τ=m*τ, m≧2; providing timing between drops for printing consecutive pixels is τ=a*τwhere a is an integer≧m; forming non-print drops and print drops according to the liquid pattern data; delaying the timing of the pulses for the drop forming energy pulses sent to the drop forming transducers of group number g relative to the drop forming energy pulses sent to the transducers of a first group by a delay time τ, where τ=g*(INT(a/n)+1/n)*τ+τwhere g is an integer

-

Phase Shifts For Printing At Two Speeds

view source -

US Patent:8231207, Jul 31, 2012

-

Filed:Nov 6, 2009

-

Appl. No.:12/613699

-

Inventors:Kim W. Montz - Webster NY, US

Todd R. Griffin - Webster NY, US

David L. Jeanmaire - Brockport NY, US

Robert Link - Webster NY, US -

Assignee:Eastman Kodak Company - Rochester NY

-

International Classification:B41J 2/07

B41J 29/38

B41J 2/15

B41J 2/12 -

US Classification:347 74, 347 9, 347 11, 347 41, 347 78

-

Abstract:The method includes forming first size drops by applying drop forming pulses during a unit time period τ; forming second size drops by applying drop forming pulses during a second size drop time period, τm, which is a multiple, m, of the unit time period; forming the corresponding plurality of drop forming energy pulse sequences so as to form non-print drops and print drops; delaying the timing of the drop forming energy pulses sent to the transducers of the second group relative to the drop forming energy pulses sent to the transducers of the first group by a delay time τ, characterized by τbeing equal to d*τwhere d is 1 to 9, when printing at a first speed and τapproximately equal to f*τtimes where f is 1 to 9, f is greater than d when printing at a speed slower than the first speed.

-

Process For Making An Organic Light-Emitting Device

view source -

US Patent:20060273713, Dec 7, 2006

-

Filed:Jun 2, 2005

-

Appl. No.:11/143167

-

Inventors:Rajesh Mehta - Rochester NY, US

Ramesh Jagannathan - Rochester NY, US

Bradley Houghtaling - Rochester NY, US

Robert Link - Webster NY, US

Kelly Robinson - Fairport NY, US

Ross Sprout - Rochester NY, US -

International Classification:H01L 51/50

H01L 51/56 -

US Classification:313504000, 428917000, 428690000, 427066000

-

Abstract:In accordance with one embodiment, the present invention is directed towards a process for forming an organic electroluminescent device comprising depositing on a substrate at least first and second electrode layers and an organic EL element comprising one or more organic material layers between the first and second electrode layers, wherein at least one organic material layer of the EL element is deposited by providing a continuous stream of amorphous solid particles of organic material suspended in at least one carrier gas, the solid particles having a volume-weighted mean particle diameter of less than 500 nm, and depositing particles of the organic material to form a thin uniform layer of the organic material on the substrate surface.

-

Deposition Of Uniform Layer Of Desired Material

view source -

US Patent:20060275542, Dec 7, 2006

-

Filed:Jun 2, 2005

-

Appl. No.:11/143180

-

Inventors:Rajesh Mehta - Rochester NY, US

Ramesh Jagannathan - Rochester NY, US

Bradley Houghtaling - Rochester NY, US

Robert Link - Webster NY, US

Kelly Robinson - Fairport NY, US

Ross Sprout - Rochester NY, US

Kenneth Reed - Rochester NY, US

Alok Verma - Rochester NY, US

Scott Mahon - Rochester NY, US

Robledo Gutierrez - Rochester NY, US

Thomas Blanton - Rochester NY, US

Jill Fornalik - Rochester NY, US -

International Classification:B05D 1/12

-

US Classification:427180000

-

Abstract:A process for the deposition of a thin film of a desired material on a surface comprising: (i) providing a continuous stream of amorphous solid particles of desired material suspended in at least one carrier gas, the solid particles having a volume-weighted mean particle diameter of less than 500 nm, at an average stream temperature below the glass transition temperature of the solid particles of desired material, (ii) passing the stream provided in (i) into a heating zone, and heating the stream in the heating zone to elevate the average stream temperature to above the glass transition temperature of the solid particles of desired material, wherein no substantial chemical transformation of the desired material occurs due to heating of the desired material, (iii) exhausting the heated stream from the heating zone through at least one distributing passage, at a rate substantially equal to its rate of addition to the heating zone in step (ii), wherein the carrier gas does not undergo a thermodynamic phase change upon passage through heating zone and distribution passage, and (iv) exposing a receiver surface that is at a temperature below the temperature of the heated stream to the exhausted flow of the heated stream, and depositing particles of the desired material to form a thin uniform layer of the desired material on the receiver surface.

-

Continuous Printer With Actuator Activation Waveform

view source -

US Patent:20110242169, Oct 6, 2011

-

Filed:Apr 1, 2010

-

Appl. No.:12/752561

-

Inventors:Robert Link - Webster NY, US

James L. Bello - Rochester NY, US

Todd R. Griffin - Webster NY, US -

International Classification:B41J 29/38

-

US Classification:347 10

-

Abstract:A method for operating a drop generating device for selective formation of large-volume droplets and small-volume droplets, said method includes the steps of defining a small-drop waveform at least a pulse to form a small volume drop; defining a large-drop waveform that includes a set of pulses to form a large volume drop; creating a sequence of waveforms comprising waveforms of the small-drop and large-drop waveforms in response to image data the sequence of waveforms; and selectively inserting a perturbation pulse in the time interval between pulses of any two consecutive waveforms.

Name / Title

Company / Classification

Phones & Addresses

Director

123 College.Com, Inc.

Management Consultants

Management Consultants

1701 W. Hillsboro Blvd., Suite 303, Deerfield Beach, FL 33442

(954)4811234, (954)4811236

(954)4811234, (954)4811236

Vice President Of Engineering And Manufacturing

Charis Homes Inc

Nursing and Personal Care Facilities

Nursing and Personal Care Facilities

62 Gatewood Dr, Marietta, GA 30068

Chief Of Anesthesiology

The Hardin Memorial Hospital Foundation Inc

Colleges, Universities, and Professional Scho...

Colleges, Universities, and Professional Scho...

913 N Dixie Ave, New York, NY 10001

Director Marketing

The Legal Aid Society

Legal Services

Legal Services

199 Water St., New York, NY 10038

Director

The Legal Aid Society

Legal Services Office

Legal Services Office

199 Water St, New York, NY 10038

(212)5773300

(212)5773300

Medical Doctor

Dr. Robert M. Lembo, MD

Medical Doctor's Office

Medical Doctor's Office

462 1 Ave, New York, NY 10016

Robert Link MD

Internist

Internist

462 1 Ave, New York, NY 10016

(212)5627691

(212)5627691

Engineer, Vice President Of Engineering And Manufacturing

CHARIS HOMES, INC

Assisted Living Care

Assisted Living Care

62 Gatewood Dr, Marietta, GA 30068

(770)5090681

(770)5090681

Isbn (Books And Publications)

License Records

Robert Link

License #:

41442 - Expired

Category:

Professional

Issued Date:

Sep 13, 2004

Robert P Link

License #:

RS153808A - Expired

Category:

Real Estate Commission

Type:

Real Estate Salesperson-Standard

Resumes

Field Engineer - Drilling

view sourcePosition:

Field Engineer - Drilling at Chesapeake Energy

Location:

Oklahoma City, Oklahoma

Industry:

Oil & Energy

Work:

Chesapeake Energy - Oklahoma City, Oklahoma Area since Aug 2012

Field Engineer - Drilling

Chesapeake Energy - Oklahoma City, Oklahoma Area May 2012 - Aug 2012

Drilling Engineer - Intern - Utica Shale

Field Engineer - Drilling

Chesapeake Energy - Oklahoma City, Oklahoma Area May 2012 - Aug 2012

Drilling Engineer - Intern - Utica Shale

Education:

University of Missouri-Rolla 2010 - 2012

Master's degree, Petroleum Engineering Emporia State University 2006 - 2009

Bachelor's degree, Biochemistry and Molecular Biology

Master's degree, Petroleum Engineering Emporia State University 2006 - 2009

Bachelor's degree, Biochemistry and Molecular Biology

Robert Link

view source

Robert Link

view sourceSkills:

Microsoft Excel

Powerpoint

Powerpoint

Licensing Specialist At Microsoft

view sourcePosition:

Licensing Specialist at Microsoft

Location:

Greater Atlanta Area

Industry:

Computer Software

Work:

Microsoft

Licensing Specialist

Licensing Specialist

Education:

University of Rochester - William E. Simon Graduate School of Business Administration 1996 - 1997

Robert Link

view sourceLocation:

United States

Lawyers & Attorneys

Robert O. Link, New York NY - Lawyer

view sourceAddress:

Cadwalader, Wickersham & Taft LLP

1 World Financial Ctr, New York, NY 10281

(212)5046000 (Office)

1 World Financial Ctr, New York, NY 10281

(212)5046000 (Office)

Licenses:

New York - Currently registered 1985

Education:

Univ of Tennessee

Robert Sumter Link Jr. - Lawyer

view sourceLicenses:

Virginia - Authorized to practice law 1980

Robert Michael Link, Rego Park NY - Lawyer

view sourceAddress:

Sweeney, Gallo, Reich & Bolz LLP

9525 Queens Blvd Fl 11, Rego Park, NY 11374

(866)4159391 (Office), (866)4159391 (Fax)

9525 Queens Blvd Fl 11, Rego Park, NY 11374

(866)4159391 (Office), (866)4159391 (Fax)

Licenses:

New York - Currently registered 2010

Education:

City University of New York School of Law at Queens College

Degree - JD

Degree - JD

Specialties:

Real Estate - 34%

Wills / Living Wills - 33%

Foreclosure - 33%

Wills / Living Wills - 33%

Foreclosure - 33%

Robert E. Link, East Norwich NY - Lawyer

view sourceAddress:

Robert E.Link III

East Norwich, NY 11732

(516)3069537 (Office)

East Norwich, NY 11732

(516)3069537 (Office)

Licenses:

New York - Currently registered 1988

Education:

St Johns University

Robert Link - Lawyer

view sourceOffice:

Link & Broderson

Specialties:

Commercial Law

Estate Planning and Probate

General Practice

Real Estate

Estate Planning and Probate

General Practice

Real Estate

ISLN:

905423027

Admitted:

1978

University:

University of Kentucky, B.S., 1975

Law School:

University of Kentucky, J.D., 1978

Robert M. Link, Rego Park NY - Lawyer

view sourceOffice:

Sweeney, Gallo, Reich & Bolz L.L.P.

9525 Queens Blvd., 11Th Fl., Rego Park, NY

9525 Queens Blvd., 11Th Fl., Rego Park, NY

ISLN:

921205959

Admitted:

2010

Law School:

Queens College of the City University of New York School of Law, J.D.

Googleplus

Robert Link

Work:

CNA Financial Corporation - EDiscovery & Computer Forensics Examiner (2011)

CNA Financial Corporation - IT Security Administrator (2009-2011)

CNA Financial Corporation - IT Security Administrator (2009-2011)

Education:

Purdue University - Computer & Information Technology, South Vermillion High School - Indiana Academic Honors

About:

I'm a quirky & diverse with a broad sense of humor. I'm professional and well educated. I have pretty strong opinions... so dont fight me. :)

Tagline:

"It's too late to forget what you already know."

Robert Link

Work:

Massabni Insurance & Financial, Inc. - Associate Agent (2008)

Passport Automotive Group - Internet Sales Manager (2006-2008)

Passport Automotive Group - Internet Sales Manager (2006-2008)

Education:

Anne Arundel Community College - Biochemistry

Tagline:

A man who tells you a kind truth is rarely telling you the whole truth.

Robert Link

Work:

Chrysler Financial Corporation - Corporate Secretary (1970-1996)

Education:

University of Michigan Law School - Law, Wayne University - Business

Relationship:

Married

About:

Retired Lawyer

Robert Link

Work:

Chrysler Financial Corporation - Corporate Secretary (1970-1996)

Education:

University of Michigan Law School - Law, Wayne University - Business, Redford High School, Detroit, Michigan - College Prep

Robert Link

Education:

Florida State University - Physics, Indiana University - Astrophysics

Tagline:

Mathematician, Sage, and Philosopher

Robert Link

Work:

Tigerline AG - Senior Consultant

Robert Link

Relationship:

Married

About:

Robert Thomas Hayes Link, Esq. I've a fairly woolly footprint on the net. Those interested in my professional work are invited to drop by http://netlaw.robertlink.or... My avatar isn't there ...

Robert Link

Myspace

Robert Link Fort Lauderd...

view sourceRobert Link (Fort Lauderdale, FL)

Robert Link Kansas City MO

view sourceRobert Link (Kansas City, MO)

Jas Robert Link Denver CO

view sourceFriends:

Cassie Cushing, Susan Stafford, Lindsey Gibbs, Jenny Welp

Jason Robert Link (Denver, CO)

Robert Link Germany

view sourceFriends:

Marjo Tienari, Imogen Davies, Tino Rasch, Jessica Klein, Monika Bode

Robert Link (Germany)

Robert Link Washingt DC

view source

Robert Link

view source

Link Steave Robert Oklah...

view sourceLink Steave Robert (Oklahoma City, OK)

Link Robert Maruta

view sourceClassmates

Robert (Link) Lauer

view sourceSchools:

Dewey Fundamental Elementary School Fair Oaks CA 1973-1975, Will Rogers Junior High School Fair Oaks CA 1975-1977

Community:

Dori Galiano

Biography:

Life

I returned to my roots which is in Oklahoma "Gods Country." I will be 46 this ...

Robert Link

view sourceSchools:

Ft. Recovery High School Ft. Recovery OH 1973-1977

Community:

Pat Mccarthy, Jeremy Kunkler

Robert Link

view sourceSchools:

Central High School Barstow CA 1990-1994

Community:

James Manning, Dan Freidel, Rebecca Post

Robert Link

view sourceSchools:

California Area High School Coal Center PA 1978-1982

Community:

Barbara Andras

Robert Jones (Link)

view sourceSchools:

Craftsbury Academy Craftsbury Common VT 1994-1998

Community:

Brenda Ellis, Shaila Lawson

Robert Link

view sourceSchools:

Patchoug High School Patchogue NY 1952-1956

Community:

Wayne Caffrey, John Winecoff, Ruthann Grega, Kathleen Peters, Donald Drew

Robert Link

view sourceSchools:

Kennedy High School Port Jefferson Station NY 1967-1971

Community:

Jackie Hill, Theodore Kleppe, John Leffert, Joan Kasten, Carolynn Cokinos, Maureen Neu, Audrey Jenkins, Rose D'amico, Jane Hipschman, Sandra Chervinskis, Fran Mongello

Youtube

Get Report for Robert G Link from Marietta, GA, age ~56