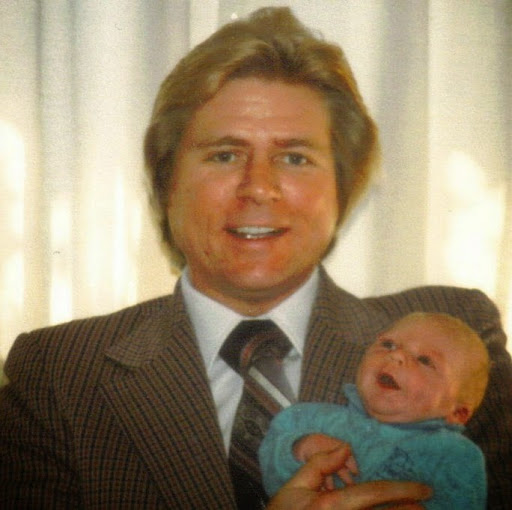

Robert A Pyles

age ~72

from Bethel Park, PA

- Also known as:

-

- Bob A Pyles

- Rob A Pyles

- Robt A Pyles

- Roberta Pyles

- Phone and address:

-

432 Galway Dr, Bethel Park, PA 15102

(412)8355844

Robert Pyles Phones & Addresses

- 432 Galway Dr, Bethel Park, PA 15102 • (412)8355844

- Evansville, IN

- Winchester, VA

- Moatsville, WV

- Philippi, WV

- 432 Galway Dr, Bethel Park, PA 15102 • (412)4252368

Work

-

Position:Healthcare Support Occupations

Specialities

Business Litigation • Eminent Domain • Real Estate Litigation • Civil Litigation • Real Estate

Lawyers & Attorneys

Robert Pyles - Lawyer

view sourceSpecialties:

Business Litigation

Eminent Domain

Real Estate Litigation

Civil Litigation

Real Estate

Eminent Domain

Real Estate Litigation

Civil Litigation

Real Estate

ISLN:

915779107

Admitted:

2004

University:

University of Nevada at Reno, B.A., 1997

Law School:

Gonzaga University School of Law, J.D., 2001

License Records

Robert B Pyles

License #:

2705049508 - Expired

Category:

Contractor

Issued Date:

Mar 19, 1999

Expiration Date:

Mar 31, 2005

Type:

Class B

Medicine Doctors

Robert L. Pyles

view sourceSpecialties:

Psychiatry

Work:

Robert L Pyles MD PC

367 Worcester St, Wellesley Hills, MA 02481

(781)2356211 (phone)

367 Worcester St, Wellesley Hills, MA 02481

(781)2356211 (phone)

Education:

Medical School

Harvard Medical School

Graduated: 1962

Harvard Medical School

Graduated: 1962

Languages:

English

Description:

Dr. Pyles graduated from the Harvard Medical School in 1962. He works in Wellesley Hills, MA and specializes in Psychiatry. Dr. Pyles is affiliated with Newton-Wellesley Hospital.

Name / Title

Company / Classification

Phones & Addresses

Principal

Robert R Pyles Sr

Nonclassifiable Establishments

Nonclassifiable Establishments

Rr 1 BOX 164, Cascade, WV 26542

Incorporator

TUNNELTON COMMUNITY AMBULANCE SERVICE, INC

Health Care and Social Assistance · Ambulatory Health Care Services · Other Ambulatory Health Care Services

Health Care and Social Assistance · Ambulatory Health Care Services · Other Ambulatory Health Care Services

5142 S Preston Hwy, Tunnelton, WV 26444

Tunnelton, Tunnelton, WV 26444

Tunnelton, Tunnelton, WV 26444

QUALITY FLEET REPAIR LLC

HARRISON-PYLES FUNERAL HOME, LTD

DIRT GRINDERS MAGAZINE, LLC

FAMILY TRUST INSURANCE AGENCY, LTD

Us Patents

-

Process For Preparing A Photochromic Lens

view source -

US Patent:6367930, Apr 9, 2002

-

Filed:Dec 30, 1999

-

Appl. No.:09/476251

-

Inventors:Pia I. Santelices - Portland OR

James N. Rieck - Wheeling WV

Jack C. Chan - Coraopolis PA

Sivaram Krishnan - Pittsburgh PA

William G. Curtis - Sewickley PA

Robert Allen Pyles - Bethel Park PA -

Assignee:Bayer Corporation - Pittsburgh PA

-

International Classification:G02C 710

-

US Classification:351177, 351163, 351166

-

Abstract:A process for making a photochromic optical lens is disclosed. In a first embodiment of the process a multi-plied laminate, containing a ply of photochromic thermoplastic polyurethane (herein âTPUâ) and a ply containing thermoplastic polycarbonate, is first placed in the cavity of a suitable mold. The ply that contains polycarbonate resin is placed facing the cavity. Thermoplastic polycarbonate resin is then injected into the cavity. In a second embodiment, referred to as an over-mold method, polycarbonate is first injection molded into a molding cavity to form a substrate. Photochromic TPU is, in a subsequent step, injected into the cavity to form a superstrate overlay. In both embodiments, the articles thus molded are suitable for the preparation of optical lenses.

-

Process For Making Dyed Articles

view source -

US Patent:6733543, May 11, 2004

-

Filed:Mar 26, 2002

-

Appl. No.:10/106788

-

Inventors:Robert A. Pyles - Bethel Park PA

Rick L. Archey - Pleasant Hills PA -

Assignee:Bayer Polymers LLC - Pittsburgh PA

-

International Classification:D06P 500

-

US Classification:8506, 8509, 8510, 8512, 8514, 8515, 8516, 8609, 8611

-

Abstract:A process of dyeing a molded article is disclosed. The process entails immersing at least a portion of the article in a dyeing bath, retaining the portion in the bath for a period of time sufficient to allow an amount of dye to diffuse into the article, and removing said article from the bath. The molded article comprises a polymeric resin such as (co)polyester, (co)polycarbonates, acrylonitrile-butadiene-styrene, polyamide, polyurethane, polyalkyl(meth)acrylate, allyldiglycol carbonate and styrene copolymers. The dyeing bath contains in addition to dye, water, a plasticizing agent and a leveling agent.

-

Dip-Dyeable Polycarbonate Process

view source -

US Patent:6749646, Jun 15, 2004

-

Filed:Nov 7, 2001

-

Appl. No.:10/040178

-

Inventors:Robert A. Pyles - Bethel Park PA

Rick L. Archey - Pleasant Hills PA -

Assignee:Bayer Polymers LLC - Pittsburgh PA

-

International Classification:D06P 700

-

US Classification:8506, 8509, 8510, 8512, 8514, 8515, 8516

-

Abstract:A process for tinting of articles molded from a polymeric resin is disclosed. Preferably, the article is molded from polycarbonate and the process entails immersing the molded article in a dye bath that contains water, dye, a carrier and an optional surfactant. The carrier is a compound conforming to wherein R and R independently denote H or C alkyl, benzyl, benzoyl or phenyl radical which may be substituted in the aromatic ring by alkyl and or halogen, preferably R =butyl, R =H, n is 2 or 3 and m is 2 to 35. The method is especially useful in the manufacture of tinted lenses.

-

Composition Comprising A Dye

view source -

US Patent:6929666, Aug 16, 2005

-

Filed:Mar 2, 2004

-

Appl. No.:10/791114

-

Inventors:Robert A. Pyles - Bethel Park PA, US

Rick L. Archey - Pleasant Hills PA, US -

Assignee:Bayer Materialscience LLC - Pittsburgh PA

-

International Classification:C09B067/40

-

US Classification:8576, 8594, 8609, 8611

-

Abstract:A composition of matter (e. g. , a molded article) is described. More particularly, the composition of matter includes: (a) a resinous component selected from at least one member of the group consisting of (co)polyester, (co)polycarbonates, acrylontrile-butadiene-styrene, polyamide, polyurethane, polyalkyl(meth)acrylate and styrene copolymers; (b) at least one dye; (c) a carrier represented by the following formula,R[—O—(CH)]ORwherein Ris butyl, Ris H, n is 2 or 3, and m is 2-35; and (d) optionally emulsifier. Also described is a dye bath that includes: (a) water; (b) at least one dye; (c) a carrier represented by the above formula; and (d) optionally an emulsifier.

-

Process For Making Dyed Articles

view source -

US Patent:6949127, Sep 27, 2005

-

Filed:Mar 9, 2004

-

Appl. No.:10/796523

-

Inventors:Robert A. Pyles - Bethel Park PA, US

Rick L. Archey - Pleasant Hills PA, US -

Assignee:Bayer MaterialScience LLC - Pittsburgh PA

-

International Classification:D06P001/60

D06P001/64 -

US Classification:8506, 8509, 8510, 8512, 8514, 8515, 8516, 8609, 8611

-

Abstract:A process of dyeing a molded article is disclosed. The process entails immersing at least a portion of the article in a dyeing bath, retaining the portion in the bath for a period of time sufficient to allow an amount of dye to diffuse into the article, and removing said article from the bath. The molded article comprises a polymeric resin such as (co)polyester, (co)polycarbonates, acrylonitrile-butadiene-styrene, polyamide, polyurethane, polyalkyl(meth)-acrylate, allyldiglycol carbonate and styrene copolymers. The dyeing bath contains in addition to dye, water, a plasticizing agent and a leveling agent.

-

Process For Tinting Plastic Articles

view source -

US Patent:6994735, Feb 7, 2006

-

Filed:May 8, 2003

-

Appl. No.:10/434242

-

Inventors:Robert A. Pyles - Bethel Park PA, US

David M. Derikart - Tarentum PA, US

Rick L. Archey - Pleasant Hills PA, US

Michael Nikolakopoulos - Pittsburgh PA, US -

Assignee:Bayer Materialscience LLC - Pittsburgh PA

-

International Classification:D06P 1/613

-

US Classification:8609, 8506, 8509, 8510, 8512, 8513, 8514, 8515

-

Abstract:A process for tinting a molded article is disclosed. The process entails applying by spraying or by flow coating a hot, dye-solution onto at least a portion of the surface of a molded article to obtain a tinted article and washing the tinted article. In addition to the dissolved dye, the dye solution that is substantially free of particulate matter contains an aqueous solution of a carrier and an optional emulsifier. The article is one molded of a thermoplastic molding composition. In an embodiment of the invention, the dye solution is prepared by filtering a hot aqueous solution through a bag filter that contains a dye to obtain a hot, dye-solution. In a further embodiment, activated carbon is used to purify the dye solution to obtain a dye-free aqueous solution.

-

Composition Of Matter Comprising A Dye

view source -

US Patent:7094263, Aug 22, 2006

-

Filed:Mar 14, 2005

-

Appl. No.:11/080799

-

Inventors:Robert A. Pyles - Bethel Park PA, US

Rick L. Archey - Pleasant Hills PA, US -

Assignee:Bayer Materialscience LLC - Pittsburgh PA

-

International Classification:C09B 29/00

C09B 67/38 -

US Classification:8552, 8576, 8609, 8611, 8618, 8662, 524190, 524257, 524258, 524317, 524376, 524378, 524543

-

Abstract:A composition of matter (e. g. , a molded article) is described. More particularly, the composition of matter includes: (a) a resinous component selected from at least one member of the group consisting of (co)polyester, (co)polycarbonates, acrylonitrile-butadiene-styrene, polyamide, polyurethane, polyalkyl(meth)acrylate and styrene copolymers; (b) at least one water-insoluble dye; (c) a carrier represented by the following formula,R[—O—(CH)]ORwherein Ris butyl, Ris H, n is 2 or 3, and m is 2–35; (d) an emulsifier that is poly(oxy-1,2-ethanediyl), alpha-phenyl-omega-hydroxy, styrenated; and (e) a particulate or plate-like material, such as metal flakes.

-

Method Of Dyeing A Plastic Article

view source -

US Patent:7175675, Feb 13, 2007

-

Filed:Dec 11, 2003

-

Appl. No.:10/733111

-

Inventors:Robert A. Pyles - Bethel Park PA, US

Rick L. Archey - Pleasant Hills PA, US

David M. Derikart - Tarentum PA, US -

Assignee:Bayer MaterialScience LLC - Pittsburgh PA

-

International Classification:D06P 5/00

-

US Classification:8506, 8509, 8510, 8514, 8515, 8516, 8611

-

Abstract:In the method of the present invention a plastic article (e. g. , a molded article of thermoplastic polycarbonate) is immersed at least partially in a dye bath which includes one or more dyes, water, at least one carrier, and at least one diol. The dye bath contains: (i) at least one dye (e. g. , a static and/or photochromic dye); (ii) water; (iii) at least one carrier represented by the following general formula I,R—O—(CH)—OHIwherein R is a radical selected from linear or branched C–Calkyl, benzyl, benzoyl and phenyl, and n is 2 or 3; and (iv) a diol selected from at least one of linear or branched C–Caliphatic diols, poly(C–Calkylene glycol), cycloaliphatic diols having from 5 to 8 carbon atoms in the cyclic ring, monocyclic aromatic diols, bisphenols and hydrogenated bisphenols. In an embodiment of the present invention, the carrier is ethyleneglycol butyl ether, and the diol is diethylene glycol. The present invention also relates to a method of separating the dye from the water, carrier and diol components of the dye bath, by contacting the dye bath with particulate activated carbon.

Resumes

New Business Development

view sourceLocation:

Pittsburgh, PA

Industry:

Chemicals

Work:

Bayer Materialscience

New Business Development

Mt Vernon In Feb 1981 - Nov 1987

General Electric Plastics

Usda Apr 1979 - Feb 1981

Post Doc Consultant

New Business Development

Mt Vernon In Feb 1981 - Nov 1987

General Electric Plastics

Usda Apr 1979 - Feb 1981

Post Doc Consultant

Education:

Texas A&M University 1975 - 1979

Doctorates, Doctor of Philosophy, Chemistry West Virginia University 1971 - 1975

Bachelors, Bachelor of Science, Chemistry

Doctorates, Doctor of Philosophy, Chemistry West Virginia University 1971 - 1975

Bachelors, Bachelor of Science, Chemistry

Robert Pyles

view source

Robert Pyles

view sourceSkills:

Troubleshooting

Team Leadership

Teaching

Team Leadership

Teaching

Youtube

Robert Pyles

view source

Robert Pyles

view source

Robert Pyles

view source

Robert D Pyles

view source

Robert Pyles

view source

Robert Pyles

view source

Robert Pyles

view source

Robert Pyles

view sourceGoogleplus

Robert Pyles

Work:

Quantum Health - Director of Infrastructure

IBM - Software Enginer Manager (2010-2011)

Sterling Commerce - Manager, Datacenter Operations (2005-2010)

DeJong - IT Manager (2001-2005)

IBM - Software Enginer Manager (2010-2011)

Sterling Commerce - Manager, Datacenter Operations (2005-2010)

DeJong - IT Manager (2001-2005)

Education:

Ohio State University - Geographic Information Systems, Ohio State University - History, Franklin University - Managing Information Systems

Tagline:

You are not a beautiful and unique snowflake.

Robert Pyles

Robert Pyles

Robert Pyles

Robert Pyles

Robert Pyles

Robert Pyles

Classmates

Robert Pyles

view sourceSchools:

Cumberland Township High School Carmichaels PA 1945-1949

Community:

Patricia Rutkosky, William Savage, Peggy Shaffer, Richard Dugan

Robert Pyles

view sourceSchools:

Cumberland Township High School Carmichaels PA 1946-1949

Community:

Patricia Rutkosky, William Savage, Peggy Shaffer, Richard Dugan

Robert Pyles

view sourceSchools:

Graham High School Graham TX 1971-1975

Robert Pyles

view sourceSchools:

Eastern High School Wrightsville PA 1990-1994

Community:

Gilbert Folckomer

Robert Pyles

view sourceSchools:

Calhoun County Training High School Anniston AL 1952-1956

Community:

Paul Gaston

Robert Pyles

view sourceSchools:

Knob Noster Elementary School Knob Noster MO 1967-1968

Robert Pyles | Clermont N...

view source

Robert Pyles, McClintock ...

view sourceMyspace

Get Report for Robert A Pyles from Bethel Park, PA, age ~72