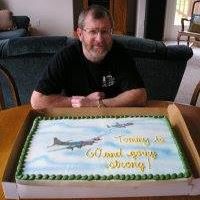

Thomas Larry Reavis

age ~80

from Winston Salem, NC

- Also known as:

-

- Thomas L Reavis

- Tom L Reavis

- Larry Reavis

- Lawrence Reavis

- Laurence Reavis

- Phone and address:

- 1993 Stonewood Dr, Winston Salem, NC 27103

Thomas Reavis Phones & Addresses

- 1993 Stonewood Dr, Winston Salem, NC 27103

- 4325 Prestwick Pl, Winston Salem, NC 27106

- 2901 Burlwood Dr, Winston Salem, NC 27103

- Murrells Inlet, SC

Resumes

Thomas Reavis

view source

Thomas Reavis

view source

Thomas Reavis

view sourceLocation:

United States

Thomas Reavis

view sourceLocation:

United States

Us Patents

-

Hosiery Manipulation Device And Method

view source -

US Patent:61926558, Feb 27, 2001

-

Filed:Aug 31, 1999

-

Appl. No.:9/386616

-

Inventors:William H. Todd - Winston-Salem NC

Joseph L. Collins - Clemmons NC

Thomas A. Reavis - King NC

C. Michael Funderburk - East Bend NC

Clay A. Ferriola - Yadkinville NC -

Assignee:Todd Motion Controls, Inc. - Winston Salem NC

-

International Classification:B65B 3550

B65B 3556

B65B 1300 -

US Classification:53397

-

Abstract:A device to manipulate hosiery comprises a swift-tack apparatus joined to a j-hook magazine which selectively attaches a swift tack to a hosiery stack with or without a j-hook. The hosiery stack is then selectively inverted by a pair of rotatable clamps. The hosiery stack is then selectively rotated to a desired orientation by a turntable. The hosiery stack is then stacked with other hosiery stacks by means of a drop arrangement onto a lift plate. The combined stacks are then selectively attached one to the other by a second swift-tack apparatus. The above manipulations are effectuated preferably by pneumatic power and a plurality of pusher plates and lift plates.

-

Automated Bagging Apparatus And Method

view source -

US Patent:59963204, Dec 7, 1999

-

Filed:Mar 13, 1998

-

Appl. No.:9/042677

-

Inventors:William H. Todd - Winston-Salem NC

Joseph L. Collins - Clemmons NC

Thomas A. Reavis - King NC -

Assignee:Todd Motion Controls, Inc. - Winston Salem NC

-

International Classification:B65B 6124

B65B 4314

B65B 706 -

US Classification:53526

-

Abstract:An automated bagging apparatus for use in the hosiery industry which tightens the bag around the hosiery articles prior to sealing to eliminate any extra bag space. This tightening effect is accomplished by holding the articles in place while extending the bag from the articles. The bag, while extended is sealed and trimmed prior to moving the sealed bag onto a conveyor belt for further handling.

-

Hosiery Banding Apparatus And Method

view source -

US Patent:60426748, Mar 28, 2000

-

Filed:Apr 23, 1998

-

Appl. No.:9/065133

-

Inventors:William H. Todd - Winston-Salem NC

Joseph L. Collins - Clemmons NC

Thomas A. Reavis - King NC

C Michael Funderburk - East Bend NC -

Assignee:Todd Motion Controls, Inc. - Winston Salem NC

-

International Classification:B65C 500

-

US Classification:156229

-

Abstract:This invention is drawn to an apparatus for applying labels to hosiery, specifically sock stacks. The sock stack travels along a first conveyor and are deposited onto a second conveyor. The second conveyor carries the sock stack to a pair of rotatable clamps. The clamps hold the sock stack and stretch it. A pneumatic cylinder moves the pair of clamps upwardly into contact with an adhesive label. The socks are rotated 360 degrees drawing the label onto the sock stack to band the same.

-

Hosiery Boarding Machine And Method

view source -

US Patent:57069875, Jan 13, 1998

-

Filed:Jun 26, 1996

-

Appl. No.:8/669835

-

Inventors:William H. Todd - Winston-Salem NC

Joseph L. Collins - Clemmons NC

Thomas A. Reavis - King NC

George M. Bowman - Mount Airy NC

Richard T. Simmons - Mount Airy NC -

Assignee:Renfro Corporation - Mount Airy NC

-

International Classification:D06C 500

-

US Classification:223 76

-

Abstract:An automatic boarding machine and method provides convenience, precision and efficiency of operation. Boarding forms are horizontally positioned for easy loading and ergonomic advantage. Microprocessor controls allow variable speed and cycle times while independent temperature controls permit precise temperature adjustments for a series of thermal pressers. The boarding machine is configured to provide space saving circular movement of a plurality of forms which pass sequentially through a moisture treatment, heated presses, and an unloader. The processed hosiery is then stacked on a conveyor, and excess yarn ends are removed by an electrical trimmer. A control panel allows the operator to change and adjust all phases of the operation easily and quickly to insure uniformity of the finished product.

-

Sock Processing Apparatus And Method

view source -

US Patent:57881308, Aug 4, 1998

-

Filed:Jan 21, 1997

-

Appl. No.:8/784604

-

Inventors:William H. Todd - Winston-Salem NC

Joseph L. Collins - Clemmons NC

Thomas A. Reavis - King NC -

Assignee:Todd Motion Controls, Inc. - Winston Salem NC

-

International Classification:A41H 3300

B31F 700

B31F 110 -

US Classification:223 37

-

Abstract:A sock processing apparatus provides devices for folding, trimming, stacking, and compressing socks. The method provides folding socks by tucking them into a slot in a plate, closing a pair of rollers beneath the plate upon the socks, and thereafter pulling the socks through the slot under roller compression. The socks then move to a trimming station, where they are held in place while a trimmer removes excess threads. The socks are then stacked and moved to a compression station for compression prior to packaging.

Thomas Reavis

view source

Thomas Reavis IV

view source

John Thomas Reavis

view source

Thomas Reavis

view sourceClassmates

Thomas Reavis | Earl Warr...

view sourceGoogleplus

Thomas Reavis

Youtube

Get Report for Thomas Larry Reavis from Winston Salem, NC, age ~80