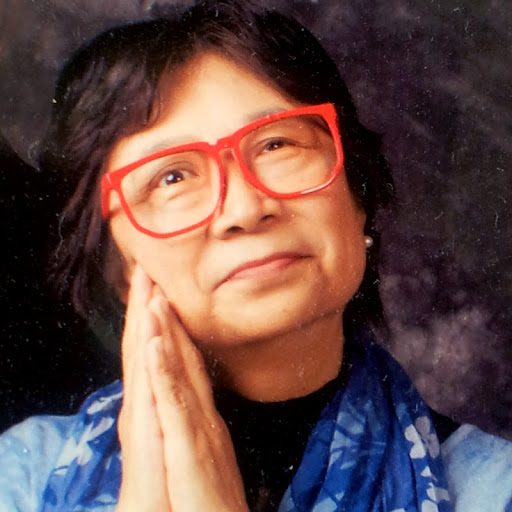

Yee Ling Cheung

age ~60

from Fremont, CA

- Also known as:

-

- Yee L Cheung

- Ling Cheung Yee

- Yeeling Cheung

Yee Cheung Phones & Addresses

- Fremont, CA

- San Mateo, CA

- San Jose, CA

- San Ardo, CA

- Castroville, CA

Specialities

Alternative Dispute Resolution • Insurance • Litigation: Commercial

Resumes

Programme Assistant

view sourceIndustry:

Arts And Crafts

Work:

Hong Kong Arts Centre

Programme Assistant

Programme Assistant

Project Engineer At Mhc Engineers, Inc.

view sourceLocation:

San Francisco Bay Area

Industry:

Mechanical or Industrial Engineering

Lawyers & Attorneys

Yee Cheung - Lawyer

view sourceSpecialties:

Alternative Dispute Resolution

Insurance

Litigation: Commercial

Insurance

Litigation: Commercial

ISLN:

1001170352

Admitted:

2021

Us Patents

-

Systems And Methods To Enhance Passive Containment Cooling System

view source -

US Patent:6618461, Sep 9, 2003

-

Filed:Feb 12, 2001

-

Appl. No.:09/781455

-

Inventors:Yee Kwong Cheung - San Jose CA

Robert E. Gamble - Mountain View CA

Atambir Singh Rao - San Jose CA -

Assignee:General Electric Company - Schenectady NY

-

International Classification:G21C 9004

-

US Classification:376283, 376282, 376277, 376296, 376299

-

Abstract:A nuclear reactor containment cooling system includes a containment vessel having a drywell and a wetwell, a cooling condenser submerged in a cooling pool of water located outside the containment vessel, a vent line extending from the condenser to a suppression pool disposed in the wetwell, and at least one drain line extending from the condenser to a condensate drain tank located in the drywell. An end of the drain line is vertically submerged below the surface of a pool of water in the drain tank. To enhance flow, a blower can be located in the drain line. The containment cooling system can include a drywell gas recirculation subsystem coupled to the vent line, and including a suction pipe coupled to the vent line, at least one valve located in the suction pipe, at least one blower coupled to the suction line, and a discharge pipe in flow communication with the drywell.

-

Passive Check Valve System

view source -

US Patent:20090154634, Jun 18, 2009

-

Filed:Dec 14, 2007

-

Appl. No.:12/000644

-

Inventors:Yee Kwong Cheung - San jose CA, US

Joel P. Melito - Wilmington NC, US -

International Classification:G21C 15/18

-

US Classification:376283

-

Abstract:A passive check valve system according to the present disclosure includes a vacuum breaker operatively connecting a wetwell and a drywell. A discharge pool of water may be provided in the drywell. A housing structure is provided in the drywell to enclose the vacuum breaker. The housing structure may have one or more discharge pipes extending into the discharge pool, and the volume of the discharge pool may be greater than an interior volume of the one or more discharge pipes.

-

Modified Passive Containment Cooling System For A Nuclear Reactor

view source -

US Patent:62434322, Jun 5, 2001

-

Filed:Nov 10, 1997

-

Appl. No.:8/966948

-

Inventors:Yee K. Cheung - San Jose CA

Douglas M. Gluntz - San Jose CA

Shyam S. Khorana - San Jose CA -

Assignee:General Electric Company - Schenectady NY

-

International Classification:G21C 900

-

US Classification:376283

-

Abstract:Modified passive containment cooling systems for cooling a reactor core of a boiling water nuclear reactor are described. The reactor core is positioned in a reactor pressure vessel which is located in a drywell of the nuclear reactor. The passive containment cooling system (PCCS), in one form, includes an IC/PCC pool, a GDCS pool, a suppression pool, and a condensate drain tank. The IC/PCC and the GDCS pool each are substantially isolated from the drywell, and the suppression pool is separated from the drywell by a wall having a spill-over hole therein. An equalizing line extends between the suppression pool and the RPV and is configured to transport water from the suppression pool to the RPV. The condensate drain tank is positioned in the drywell and includes a base wall having a sidewall extending therefrom to define a fluid retaining cavity. A steam inlet line extends from within the drywall to a set of passive containment cooling condensers, which condense steam generated within the drywall to water.

-

Gravity Driven Suction Pump System, Methods, And Apparatus

view source -

US Patent:60977787, Aug 1, 2000

-

Filed:Dec 18, 1998

-

Appl. No.:9/215892

-

Inventors:Yee K. Cheung - San Jose CA

-

Assignee:General Electric Company - Schenectady NY

-

International Classification:G21C 9012

-

US Classification:376283

-

Abstract:A gravity driven suction pump for a nuclear reactor condenser is described. The gravity driven suction pump is utilizes the potential energy of the condenser condensate to move condensible and noncondensible gases through the condenser. The gravity driven suction pump includes a drain line having a venturi section and a suction line extending from the condenser into the venturi section. The venturi section alters the flow velocity of condensate in the throat of the drain line and creates a pressure differential through the suction line to drain the noncondensible gases from the condenser.

-

Emergency Cooling System And Method

view source -

US Patent:52767205, Jan 4, 1994

-

Filed:Nov 2, 1992

-

Appl. No.:7/970504

-

Inventors:Willem J. Oosterkamp - Oosterbeek, NL

Yee K. Cheung - San Jose CA -

Assignee:General Electric Company - San Jose CA

-

International Classification:G21C 1518

-

US Classification:376283

-

Abstract:An improved emergency cooling system and method is disclosed that may be adapted for incorporation into or use with a nuclear BWR wherein a reactor pressure vessel (RPV) containing a nuclear core and a heat transfer fluid for circulation in a heat transfer relationship with the core is housed within an annular sealed drywell and is fluid communicable therewith for passage thereto in an emergency situation the heat transfer fluid in a gaseous phase and any noncondensibles present in the RPV, an annular sealed wetwell houses the drywell, and a pressure suppression pool of liquid is disposed in the wetwell and is connected to the drywell by submerged vents. The improved emergency cooling system and method has a containment condenser for receiving condensible heat transfer fluid in a gaseous phase and noncondensibles for condensing at least a portion of the heat transfer fluid. The containment condenser has an inlet in fluid communication with the drywell for receiving heat transfer fluid and noncondensibles, a first outlet in fluid communication with the RPV for the return to the RPV of the condensed portion of the heat transfer fluid and a second outlet in fluid communication with the drywell for passage of the noncondensed balance of the heat transfer fluid and the noncondensibles. The noncondensed balance of the heat transfer fluid and the noncondensibles passed to the drywell from the containment condenser are mixed with the heat transfer fluid and the noncondensibles from the RPV for passage into the containment condenser.

-

Systems And Methods For Preventing Steam Leakage Between A Drywell And A Wetwell In A Nuclear Reactor

view source -

US Patent:58964312, Apr 20, 1999

-

Filed:Jul 18, 1997

-

Appl. No.:8/896778

-

Inventors:Yee Kwong Cheung - San Jose CA

-

Assignee:General Electric Company - Schenectady NY

-

International Classification:G21C 1518

-

US Classification:376283

-

Abstract:Systems, methods, and apparatus for preventing steam leakage between a drywell and a wetwell in a nuclear reactor are described. In accordance with one embodiment of the present invention, the vacuum breaker of the nuclear reactor is coupled to a vacuum breaker condensing system which includes a condenser and a steam inlet pipe. The steam inlet pipe is substantially hollow and includes a first end, a second end, and a loop seal between the first and second ends. The first end of the pipe is positioned adjacent the drywell and the second end of the pipe is coupled to the vacuum breaker. The condenser is positioned proximate the steam inlet pipe and includes an inlet, an outlet, and a plurality of condenser tubes. The condenser inlet and condenser outlet are each coupled to a pool of water, e. g. , the Gravity Driven Cooling System pool, and configured to draw water from the pool of water and through the condenser tubes to substantially condense steam flowing through the steam inlet pipe.

-

Analog And Audio Mixed-Signal Front End For 4G/Lte Cellular System-On-Chip

view source -

US Patent:20150194979, Jul 9, 2015

-

Filed:Dec 30, 2014

-

Appl. No.:14/586866

-

Inventors:- Irvine CA, US

Xinyu YU - San Jose CA, US

Fang LIN - Los Gatos CA, US

Yee Ling CHEUNG - Irvine CA, US

Michael INERFIELD - Sunnyvale CA, US -

International Classification:H03M 1/18

H04M 1/02

H04B 1/40

H03M 1/66 -

Abstract:A CMOS analog and audio front-end circuit includes an enhanced analog-to-digital converter (ADC) that achieves a desired signal-to-noise-and-distortion (SNDR) and an analog-front-end transmit (TX) digital-to-analog converter (DAC). The enhanced ADC includes an improved single Op-Amp resonator coupled to a feed-forward loop and can substantially reduce signal transfer function (STF) peaking of the enhanced ADC. The CMOS analog and audio front-end circuit is integrated with a baseband processor.

Youtube

Plaxo

Ernest Yee Cheung Wong

view sourceCanada

Yee Cheung Yau

view source

Shuk Yee Cheung

view source

Yee Wai Cheung

view source

Yee Sin Cheung

view source

Yee Ma Cheung

view source

Wai Yee Cheung

view source

Yee Cheung

view source

Yan Yee Cheung

view sourceGoogleplus

Yee Cheung

Yee Cheung

Yee Cheung

Yee Cheung

Yee Cheung

Yee Cheung

Yee Cheung (Charlotte)

Yee Cheung

Myspace

Classmates

Yee Cheung

view sourceSchools:

Umana Technical High School Boston MA 1982-1986

Community:

Penny Bennett, Carlton Smith, Leroi Rodriguez, Dina Clark, Sheila Kee

Irene Suk-Yee Cheung | Da...

view source

Rebecca,Tak Yee Cheung | ...

view source

Maryknoll Convent School,...

view sourceGraduates:

Tak Yee Cheung (1986-1990),

Joyce Leung (1990-1996),

Irene Lee (1982-1984),

Mei Ling Cheung (1982-1983)

Joyce Leung (1990-1996),

Irene Lee (1982-1984),

Mei Ling Cheung (1982-1983)

Burnett High School, Rich...

view sourceGraduates:

Dennis Cheung (1988-1992),

Vinnie Cheung (2002-2006),

Ka Yee Cheung (1996-1997),

Lynne Winkler (1993-1998)

Vinnie Cheung (2002-2006),

Ka Yee Cheung (1996-1997),

Lynne Winkler (1993-1998)

Umana Technical High Scho...

view sourceGraduates:

Anthony Andrews (1990-1994),

Juliana Guerra (1978-1982),

Sahron Boyce (1988-1988),

Yee Cheung (1982-1986),

Erik Pettaway (1982-1986)

Juliana Guerra (1978-1982),

Sahron Boyce (1988-1988),

Yee Cheung (1982-1986),

Erik Pettaway (1982-1986)

Dawson High School, Westm...

view sourceGraduates:

yee Cheung (1996-2000)

Rick Hansen High School, ...

view sourceGraduates:

Harsimran Singh (2003-2004),

Christina Cheung (1999-2003),

Man Yee Cheung (2000-2004)

Christina Cheung (1999-2003),

Man Yee Cheung (2000-2004)

Flickr

Get Report for Yee Ling Cheung from Fremont, CA, age ~60