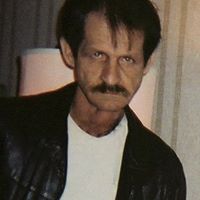

Charles Andrew Singletary

age ~72

from Clarksville, TN

- Also known as:

-

- Charles A Singletary

- Charles Andrew Sing

- Andy J Singletary

- Charles A Sing

- Andrew Singletary

- Charlesa Singletary

- Phone and address:

-

297 Ellsworth Ct, Clarksville, TN 37043

(931)3689308

Charles Singletary Phones & Addresses

- 297 Ellsworth Ct, Clarksville, TN 37043 • (931)3689308

- Whitehouse, TX

- 20257 Colony Cir, Bristol, VA 24202 • (276)6194626

Us Patents

-

Variable Capacity Compressor Having Adjustable Crankpin Throw Structure

view source -

US Patent:6446451, Sep 10, 2002

-

Filed:Mar 30, 2001

-

Appl. No.:09/820983

-

Inventors:David T. Monk - Bristol VA

Joe T. Hill - Bristol VA

Philip C. Wagner - Bristol TN

Joseph F. Loprete - Bristol TN

Michael R. Young - Bristol TN

Charles A. Singletary - Bristol VA -

Assignee:York International Corporation - York PA

-

International Classification:F25B 100

-

US Classification:622285, 62229, 417221, 417326

-

Abstract:A two-stage reciprocating compressor is provided. The compressor includes a block with a single cylinder and associated single compression chamber and single piston. The compressor further includes a crankshaft. The crankshaft has an eccentric crankpin that is operatively connected to the piston. A reversible motor is provided to rotate the crankshaft in a forward direction and in a reverse direction. An eccentric cam is rotatably mounted on the eccentric crankpin. The eccentric cam is held stationary with respect to the crankpin when the crankshaft is rotating in the forward direction. When rotating in the forward direction, the crankshaft drives the piston at a full stroke between a bottom position and a top dead center position. The eccentric cam rotates with respect to the crankpin when the crankshaft is rotating in the reverse direction. When rotating in the reverse direction, the crankshaft drives the piston at a reduced stroke between an intermediate position and the top dead center position.

-

Anti-Reverse Rotation Valve For Scroll Compressor

view source -

US Patent:56832362, Nov 4, 1997

-

Filed:Mar 21, 1996

-

Appl. No.:8/619316

-

Inventors:Mark W. Harrison - Onalaska WI

Peter A. Kotlarek - Onalaska WI

Charles A. Singletary - Whitehouse TX

John Kenneth Wollitz - Tyler TX -

Assignee:Alliance Compressors - Tyler TX

-

International Classification:F04C 1804

F04C 2900

F04C 2902

F16K 1502 -

US Classification:418 551

-

Abstract:A scroll-type refrigeration compressor has a gas-liquid mixture discharge passage extending through the driver scroll drive shaft for discharging refrigerant gas and entrained lubricant into a high pressure chamber in the compressor housing. An anti-reverse rotation valve is connected to the distal end of the drive shaft and includes a valve housing with radially extending discharge ports and a closure member movable to prevent reverse flow of high pressure gas to the scroll compression chambers to prevent reverse rotation on compressor shutdown. A pressure equalization port may be formed in the valve closure member, valve housing or the distal end of the drive shaft to allow slow bleed down of pressure from the high pressure side to the low pressure side to minimize starting torque of the drive motor. The valve may be formed from a tubular metal housing and having a plug-type closure member slidably disposed therein with the housing being press fitted in a counterbore in the end of the shaft. A gas-liquid separation baffle may be disposed around the valve housing for assisting in gas-liquid separation after the mixture is discharged from the valve housing.

-

Oil Separation And Bearing Lubrication In A High Side Co-Rotating Scroll Compressor

view source -

US Patent:54217083, Jun 6, 1995

-

Filed:Feb 16, 1994

-

Appl. No.:8/197084

-

Inventors:Robert E. Utter - Whitehouse TX

S. Boyd Wall - Tyler TX

Charles A. Singletary - Whitehouse TX

Gene M. Fields - Bristol TN

Joe T. Hill - Bristol VA

John R. Williams - Bristol TN -

Assignee:Alliance Compressors Inc. - Tyler TX

-

International Classification:F01C 104

-

US Classification:418 556

-

Abstract:A high side co-rotating refrigerant scroll compressor includes a motor disposed vertically above its compression mechanism. The discharge of gas from the compression mechanism is through the drive shaft of the drive scroll member which is rotatably supported at its distal end in an upper bearing. Upper bearing lubrication is accomplished by the disentrainment of oil from the mixture of compressed refrigerant gas and oil discharged from the compression mechanism in the vicinity of the bearing and by the direction of such disentrained oil to the bearing.

-

Variable Capacity Compressor Having Adjustable Crankpin Throw Structure

view source -

US Patent:62172875, Apr 17, 2001

-

Filed:Jan 22, 1999

-

Appl. No.:9/235288

-

Inventors:David T. Monk - Bristol VA

Joe T. Hill - Bristol VA

Philip C. Wagner - Bristol TN

Joseph F. Loprete - Bristol TN

Michael R. Young - Bristol TN

Charles A. Singletary - Bristol VA -

Assignee:Bristol Compressors, Inc. - Bristol VA

-

International Classification:F04B 4906

-

US Classification:417 45

-

Abstract:A two-stage reciprocating compressor is provided. The compressor includes a reversible motor that rotates a crankshaft. The crankshaft is connected to a piston by a mechanical system. The mechanical system drives the piston at a full stroke between a bottom position and a top dead center position when the motor is operated in a forward direction. The mechanical system drives the piston at a reduced stroke between an intermediate position and the top dead center position when the motor is operated in the reverse direction. The compressor also includes a control for selectively operating the motor in either the forward direction at a first preselected, fixed speed or in the reverse direction at a second preselected fixed speed.

Resumes

Charles Singletary

view sourceSkills:

Microsoft Word

Event Planning

Windows

Microsoft Office

Outlook

Powerpoint

Strategic Planning

Customer Service

Public Relations

Microsoft Excel

English

Html

Editing

Event Planning

Windows

Microsoft Office

Outlook

Powerpoint

Strategic Planning

Customer Service

Public Relations

Microsoft Excel

English

Html

Editing

Charles Singletary

view source

Charles Singletary

view source

Charles Singletary

view source

Charles Singletary

view sourceFlickr

Charles Singletary

view source

Charles Singletary

view source

Charles Singletary

view source

Charles Singletary III

view source

Charles Singletary

view source

Charles Singletary

view source

Charles Singletary

view source

Charles Singletary

view sourceClassmates

Charles Ernie Singletary

view sourceSchools:

Sixth Ward Junior High School Pearl River LA 1963-1972

Community:

Debra Dubuisson, Dorthy Bolden, Christine Cerenzie, Cheryl Harper

Hillside High School, Dur...

view sourceGraduates:

Charles Singletary (1960-1964),

Julian Lunsford (1992-1996),

Mariam Kasuga (1999-2003),

Theresa Jones Jones (1983-1987)

Julian Lunsford (1992-1996),

Mariam Kasuga (1999-2003),

Theresa Jones Jones (1983-1987)

Sixth Ward Junior High Sc...

view sourceGraduates:

Charles Ernie Singletary (1963-1972)

Other Social Networks

Charles Singletary Google+

view sourceNetwork:

GooglePlus

15 Aug 2011 Charles Singletary - Well...if talk is cheap, consider my silence diamonds. - Sales Specialist - Cottondale, AL - Charles "Profex" ...

Youtube

Googleplus

Charles Singletary

Charles Singletary

Myspace

Get Report for Charles Andrew Singletary from Clarksville, TN, age ~72