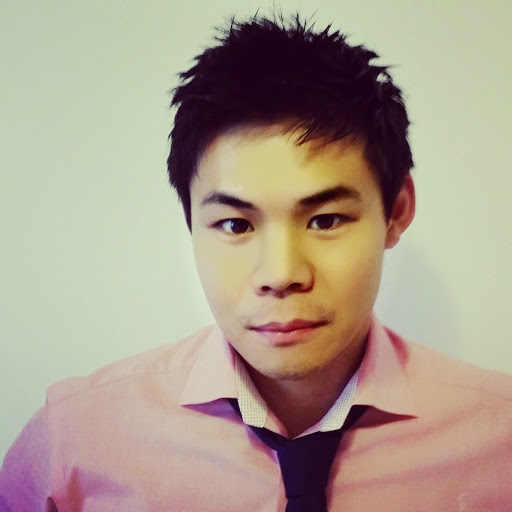

Paul L Tsang

age ~73

from Union City, CA

- Also known as:

-

- Paul Lukpong Tsang

- Paul T Tsang

- Paul L Ptsang

- Tsang Paul

- Phone and address:

-

4756 Loretta Way, Union City, CA 94587

(510)4895730

Paul Tsang Phones & Addresses

- 4756 Loretta Way, Union City, CA 94587 • (510)4895730 • (650)5933634

- 4755 Loretta Way, Union City, CA 94587

- San Carlos, CA

- San Jose, CA

- San Francisco, CA

- Foster City, CA

- Osceola, WI

Work

-

Company:Masterpiece portrait & wedding

-

Address:1160 El Camino Real, San Carlos, CA 94070

-

Phones:(650)5933634

-

Position:Owner

-

Industries:Photographic Studios, Portrait

Name / Title

Company / Classification

Phones & Addresses

Abbey Dental Centre

Dentists-General Practice

Dentists-General Practice

122 31935 S Fraser Way, Clearbrook, BC V2T 1V5

(604)8500768

(604)8500768

Owner

Masterpiece Portrait & Wedding

Photographic Studios, Portrait

Photographic Studios, Portrait

1160 El Camino Real, San Carlos, CA 94070

Website: mpwweb.com

Website: mpwweb.com

Owner

Masterpiece Portrait & Wedd

Photographic Studios, Portrait

Photographic Studios, Portrait

876 Laurel St, San Carlos, CA 94070

Website: aboutmasterpiece.com

Website: aboutmasterpiece.com

Owner

Masterpiece Portrait & Wedding

Photographers-Portrait

Photographers-Portrait

1160 El Camino Real, San Carlos, CA 94070

(650)5933634

(650)5933634

Treas

WELLS FARGO FLEET SERVICES, INC

C/O 4824 Park Gln Rd, Minneapolis, MN 55416

633 Folsom St, San Francisco, CA 94107

75 Pinehurst Way, San Francisco, CA 94117

633 Folsom St, San Francisco, CA 94107

75 Pinehurst Way, San Francisco, CA 94117

Mubeauty LLC

Retail and Wholesale and Online Sales of · Business Services at Non-Commercial Site · Nonclassifiable Establishments

Retail and Wholesale and Online Sales of · Business Services at Non-Commercial Site · Nonclassifiable Establishments

345 Capricorn Ave, Oakland, CA 94611

Abbey Dental Centre

Dentists-General Practice

Dentists-General Practice

(604)8500768

President

Hogan & Jones Chicken Inc

Us Patents

-

Method For Manufacturing Field Effect Transistors

view source -

US Patent:44425899, Apr 17, 1984

-

Filed:Mar 5, 1981

-

Appl. No.:6/240677

-

Inventors:Ven Y. Doo - San Jose CA

Paul J. Tsang - Poughkeepsie NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H01L 21265

H01L 2128 -

US Classification:29571

-

Abstract:A transistor and method of forming the same are disclosed. A thick mesa of dielectric material is grown on a semiconductor substrate and two or more layers of polycrystalline silicon grown on the vertical sides of the mesa serve a masking function to define the gate region of the transistor with high accuracy. The mesa and the two or more polycrystalline layers remain in the final device.

-

Bipolar Transistor

view source -

US Patent:43921493, Jul 5, 1983

-

Filed:Jun 15, 1981

-

Appl. No.:6/273705

-

Inventors:Cheng T. Horng - San Jose CA

Robert O. Schwenker - San Jose CA

Paul J. Tsang - Poughkeepsie NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H01L 2712

-

US Classification:357 49

-

Abstract:Disclosed is a self-aligned process for providing an improved bipolar transistor structure. The process includes the chemically etching of an intermediate insulating layer to undercut another top layer of a different insulating material in a self-aligned emitter process wherein the spacing of the emitter contact to the polysilicon base contact is reduced to a magnitude of approximately 0. 2 to 0. 3 micrometers. In addition, in the process an emitter plug is formed to block the emitter region from the heavy P+ ion dose implant of the extrinsic base.

-

Process For Fabricating Improved Bipolar Transistor Utilizing Selective Etching

view source -

US Patent:43098126, Jan 12, 1982

-

Filed:Mar 3, 1980

-

Appl. No.:6/126610

-

Inventors:Cheng T. Horng - San Jose CA

Robert O. Schwenker - San Jose CA

Paul J. Tsang - Poughkeepsie NY -

Assignee:International Business Machines Corporation - Armonk NY

-

International Classification:H01L 21265

H01L 21285

H01L 2131 -

US Classification:29578

-

Abstract:Disclosed is a self-aligned process for providing an improved bipolar transistor structure. The process includes the chemically etching of an intermediate insulating layer to undercut another top layer of a different insulating material in a self-aligned emitter process wherein the spacing of the emitter contact to the polysilicon base contact is reduced to a magnitude of approximately 0. 2 to 0. 3 micrometers. In addition, in the process an emitter plug is formed to block the emitter region from the heavy P+ ion dose implant of the extrinsic base.

Classmates

Alberta College, Edmonton...

view sourceGraduates:

Peter Tsang (1969-1973),

Dave Ottley (1964-1968),

Troy Weeks (1990-1992),

Paul Tsang Hong Yue (1967-1971),

Allan Campiou (1995-1999)

Dave Ottley (1964-1968),

Troy Weeks (1990-1992),

Paul Tsang Hong Yue (1967-1971),

Allan Campiou (1995-1999)

Hoover Middle School, San...

view sourceGraduates:

Paul Nathan (1952-1956),

Larry Minney (1956-1960),

Matthew Cogley (1987-1990),

Paul Tsang (1983-1987),

Hei Man Li (1999-2003)

Larry Minney (1956-1960),

Matthew Cogley (1987-1990),

Paul Tsang (1983-1987),

Hei Man Li (1999-2003)

Paul Tsang

view source

Paul Tsang

view source

Paul Tsang

view source

Paul C Tsang

view source

Paul Tsang

view source

Paul Tsang

view source

Paul Tsang

view source

Paul Tsang

view sourceMyspace

Youtube

Googleplus

Paul Tsang

Work:

Biglight - Designer

ACHICA - Graphic designer (2010-2013)

ACHICA - Graphic designer (2010-2013)

Paul Tsang

Education:

Leeds Metropolitan University - BSc Information System

Paul Tsang

Paul Tsang

Paul Tsang

Paul Tsang

Paul Tsang

Paul Tsang

Flickr

Get Report for Paul L Tsang from Union City, CA, age ~73